A light carbon fiber/carbon composite thermal field material and its preparation method

A thermal field material and carbon fiber technology, applied in the field of lightweight carbon fiber/carbon composite thermal field materials and their preparation, can solve the problems of poor interface bonding, poor bonding, and low production efficiency, and achieve less residual carbon and cross-linking. The effect of high density and small intermolecular distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

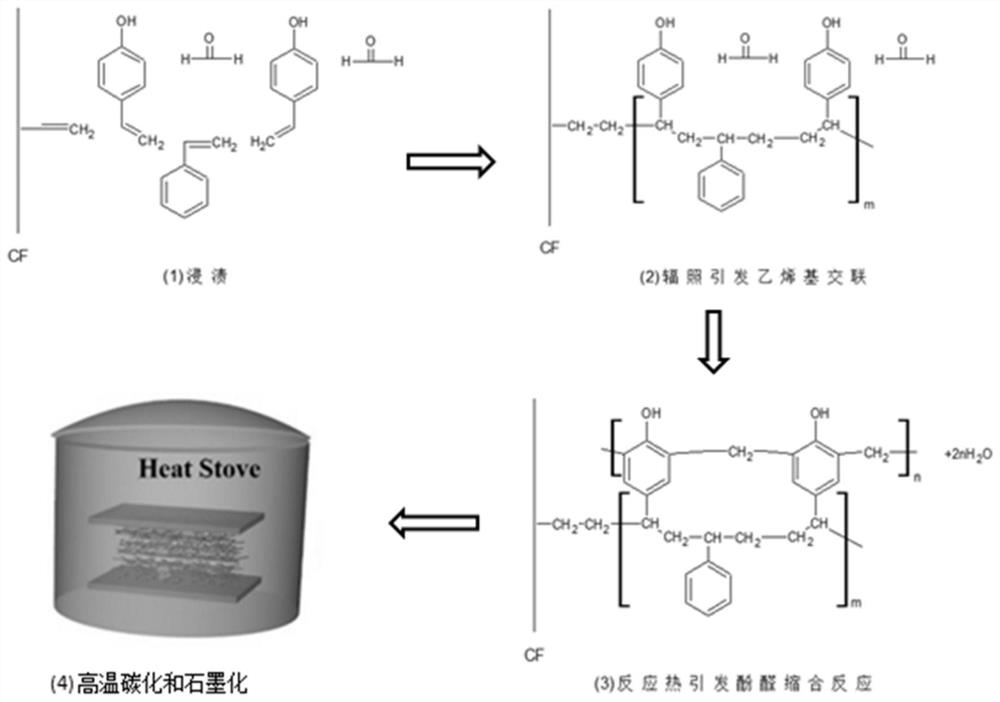

[0058] The preparation method of lightweight carbon fiber / carbon composite thermal field material comprises the following steps:

[0059] (1) Liquid phase impregnation: Prepare a new resin system (10 parts of vinylphenol, 1 part of styrene, 4 parts of formaldehyde and 0.4 parts of ammonia water), mix and stir evenly for later use; The carbon fiber soft felt is composited, and the final mass ratio of the spray liquid to the carbon fiber is 15:100;

[0060] (2) Irradiation-induced vinyl cross-linking: Lay the impregnated sample on the tray for radiation-induced vinyl cross-linking, and drive the radiation back and forth. The electron accelerator model and working conditions are GJ-2E-EB, 2MeV, 10mA. The irradiation time is 5min.

[0061] (3) Reaction heat triggers phenolic condensation reaction: the irradiated sample is quickly put into a mold for compression molding, the pressing pressure is 10MPa, no need to heat and cure for 5 hours, the vinyl cross-linked network and the p...

Embodiment 2

[0065] (1) Liquid phase impregnation: Prepare a new resin system (20 parts of vinyl phenol, 2 parts of vinyl co-crosslinking agent tripropylene glycol dipropylene ether ester, 8 parts of formaldehyde and 0.8 parts of ammonia water), mix and stir evenly for later use; then spray The method of liquid phase impregnation is used to compound it with the cut carbon fiber soft felt, and the final mass ratio of spray liquid to carbon fiber is 30:100;

[0066] (2) Irradiation-induced vinyl cross-linking: Lay the impregnated sample on the tray for radiation-induced vinyl cross-linking, and drive the radiation back and forth. The electron accelerator model and working conditions are GJ-2E-EB, 2MeV, 10mA. The irradiation time is 5min.

[0067] (3) Reaction heat triggers phenolic condensation reaction: the irradiated sample is quickly put into a mold for compression molding, the pressing pressure is 10MPa, no need to heat and cure for 5 hours, the vinyl cross-linked network and the phenol...

Embodiment 3

[0071] (1) Liquid phase impregnation: Prepare a new resin system (30 parts of vinyl phenol, 3 parts of triallyl isocyanurate, 12 parts of formaldehyde and 1.2 parts of ammonia water), mix and stir evenly for later use ; Then use the method of spraying liquid phase impregnation to compound it with the cut carbon fiber soft felt, and the final mass ratio of spraying liquid to carbon fiber is 45:100;

[0072] (2) Irradiation-induced vinyl cross-linking: Lay the impregnated sample on the tray for radiation-induced vinyl cross-linking, and drive the radiation back and forth. The electron accelerator model and working conditions are GJ-2E-EB, 2MeV, 10mA. The irradiation time is 5min.

[0073] (3) Reaction heat triggers phenolic condensation reaction: the irradiated sample is quickly put into a mold for compression molding, the pressing pressure is 10MPa, no need to heat and cure for 5 hours, the vinyl cross-linked network and the phenolic cross-linked network cross each other, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com