Lithium-sulfur battery negative electrode with high-specific-surface mesoporous protective film as well as preparation and application of lithium-sulfur battery negative electrode

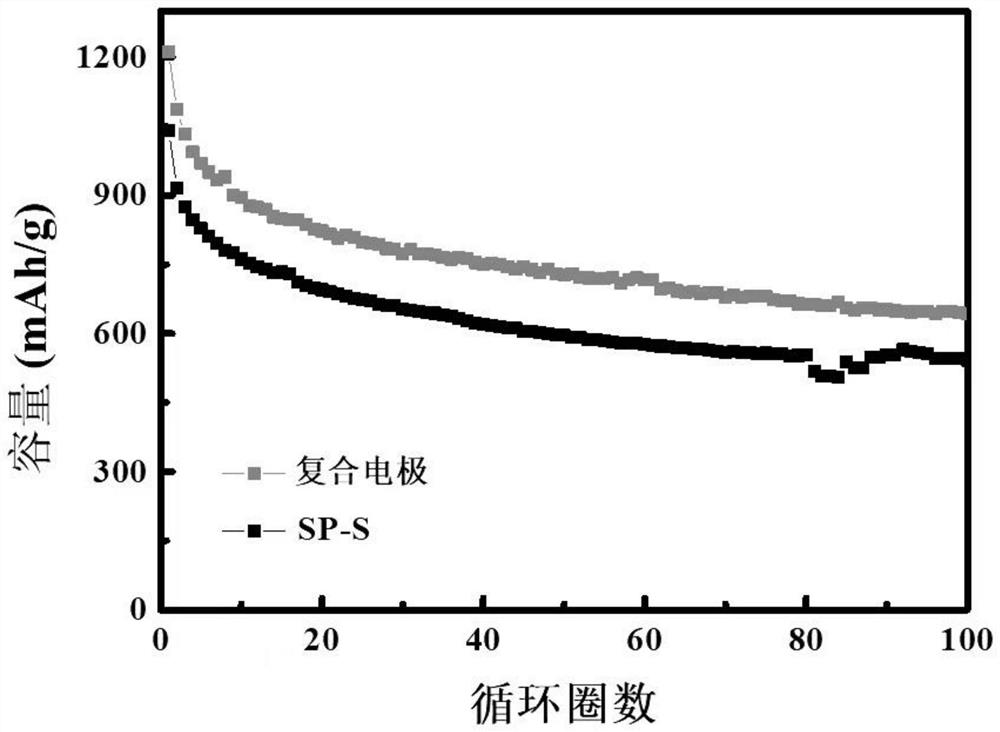

A lithium-sulfur battery, high specific surface technology, applied in the direction of battery electrodes, lithium batteries, negative electrodes, etc., can solve the problems of unsafe metal lithium anode, limit the application of metal lithium, and increase the irreversible capacity, so as to reduce the lithium current density, It is beneficial to industrial application and inhibits the effect of shuttle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

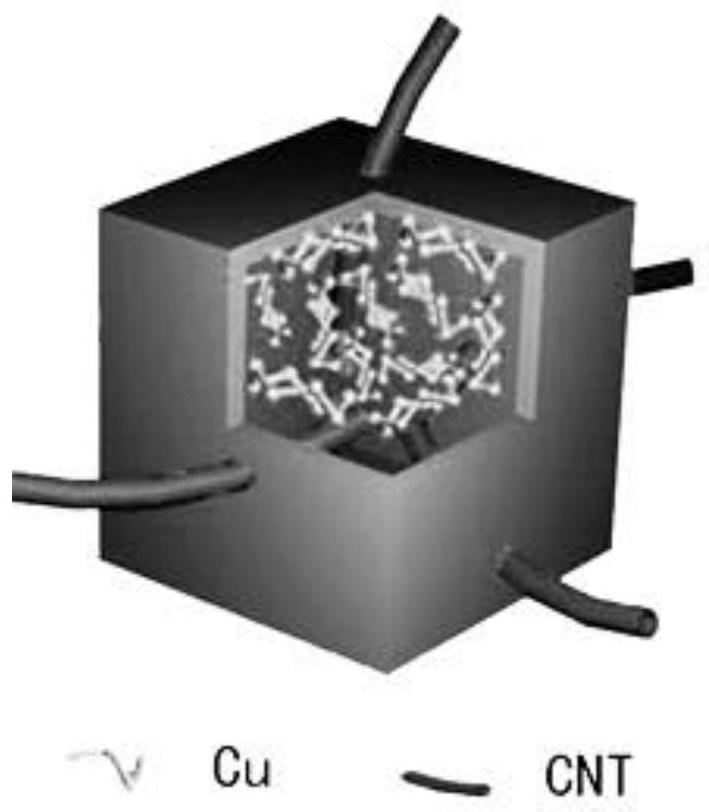

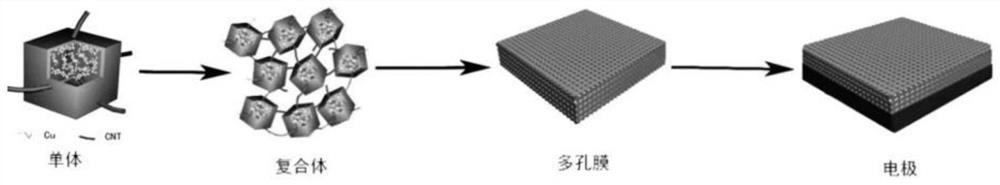

[0033] The preparation method of the polar complex is as follows:

[0034]The transition metal potassium cyanide is dissolved in water to obtain a mixed solution A, the concentration of the A solution is 1 wt%, and the transition metal is Fe; the transition metal chloride and the tubular conductive carbon material are added to water and mixed uniformly to obtain a mixed solution B, the described The concentration of solution B is 0.8wt%, and the mass ratio of conductive carbon material to transition metal chloride is 4:1; solution A is slowly dropped into solution B, heated in a water bath at 60°C for 3 hours to obtain solution C, and solution C is avoided Centrifuge after light treatment for 8 hours, wash with water and ethanol several times to obtain powder D; use different carbon sources to treat powder D with carbon coating, and then in N 2 Calcined at 400°C for 2 hours in the atmosphere to obtain egg yolk-shell polar complex E. The carbon source is sucrose; the mass rati...

Embodiment 2

[0038] The preparation method of the polar complex is as follows:

[0039] The transition metal potassium cyanide is dissolved in water to obtain a mixed solution A, the concentration of the A solution is 5 wt%, and the transition metal is Co; the transition metal chloride and the lamellar conductive carbon material are added to water and mixed uniformly to obtain a mixed solution B, The concentration of the solution B is 1.2wt%, and the mass ratio of the conductive carbon material to the transition metal chloride is 1:4; the solution A is slowly dropped into the solution B, and heated in a water bath at 70° C. for 5 hours to obtain the solution C, and the solution C After 24 hours of dark treatment, it was centrifuged, washed with water and ethanol several times to obtain powder D; powder D was treated with carbon coating with different carbon sources, and then calcined at 800°C for 5 hours in an Ar atmosphere to obtain egg yolk-shell polar complex E. The carbon source is glu...

Embodiment 3

[0043] The preparation method of the polar complex is as follows: the transition metal potassium cyanide is dissolved in water to obtain a mixed solution A, the concentration of the A solution is 1wt%, and the transition metal is Ni; the transition metal chloride and the lamellar conductive carbon material are added Mix uniformly in water to obtain a mixed solution B, the concentration of the solution B is 1.2wt%, and the mass ratio of the conductive carbon material to the transition metal chloride is 1:4; the solution A is slowly dropped into the solution B, and heated in a water bath at 70°C After 5 hours, solution C was obtained, and solution C was treated in the dark for 24 hours, then centrifuged, washed with water and ethanol several times to obtain powder D; powder D was treated with carbon coating by using different carbon sources, and then calcined at 800 ° C for 5 hours in an Ar atmosphere to obtain Yolk-shell polar complex E. The carbon source is phenolic resin; the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com