Residual oil catalytic thermal cracking and coal-to-olefin waste alkali liquor resource utilization device

A waste lye and recycling technology, which is applied in the direction of grease/oily substance/suspton removal devices, inorganic chemistry, chemical instruments and methods, etc. Realize effective removal of sulfide and sodium thiosulfate and resource utilization, etc., to achieve the effect of reducing emissions, reducing solvent replenishment and loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

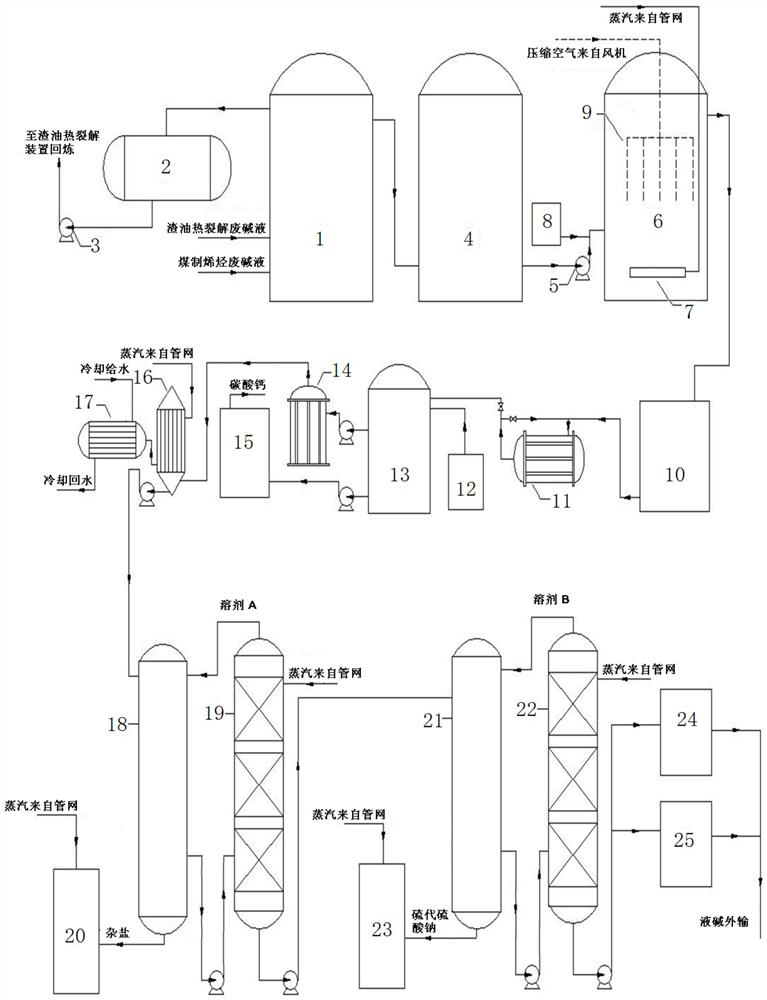

[0043] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. The examples are only used to explain the present invention, not to limit the protection scope of the present invention.

[0044] see figure 1 , the present invention proposes a waste lye mixed salt resource utilization device, which includes a waste lye degreasing section, an oxidation section, an organic matter removal section, a caustic chemical section, an evaporation concentration section, and a miscellaneous salt removal section in series , Sodium thiosulfate recovery section and liquid caustic soda modulation recovery section. Utilize above-mentioned each work section to the DCC device and MTO device in the factory area (the waste lye liquor produced by the DCC device in the factory area is much more than the waste lye liquor produced by the MTO device) in the process of alkali cleaning acid gas (referred to as slag respectively) The sp...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap