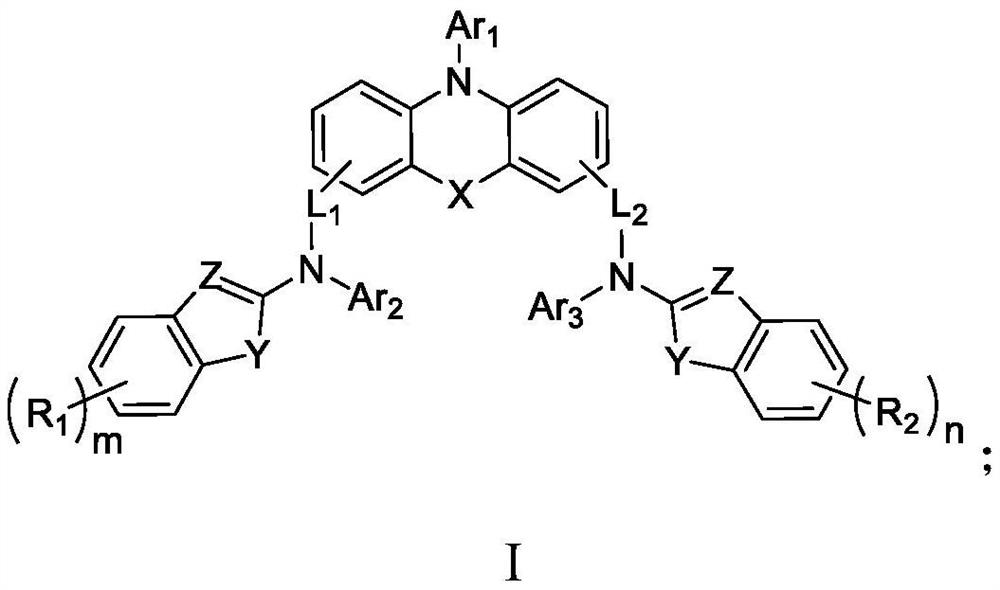

Capping layer material and preparation method thereof, organic electroluminescent device and display device

A technology of capping layer and organic layer, applied in the field of chemistry and organic luminescent materials, can solve the problems of low luminous efficiency and cannot meet high refractive index, and achieve high refractive index, improve luminous efficiency, improve luminous efficiency and service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

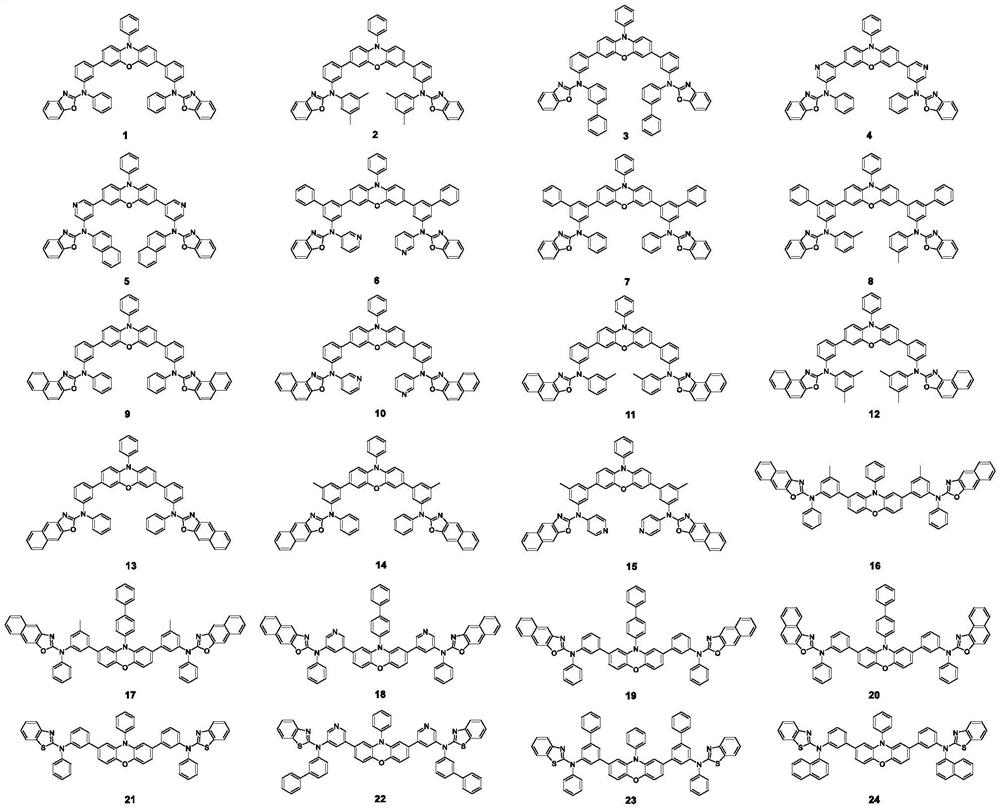

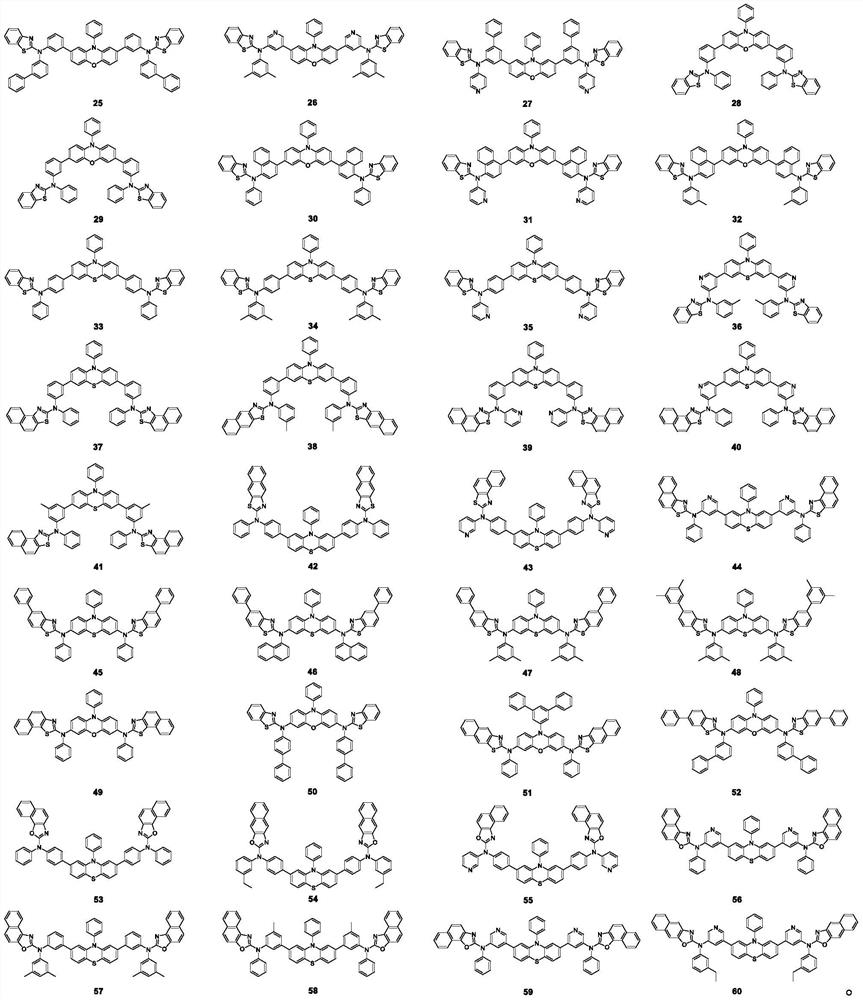

Examples

preparation example Construction

[0047] In the above technical solution, the preparation method of the capping layer material may specifically include the following steps:

[0048] S1. Under the protection of a protective atmosphere such as nitrogen, dissolve raw material A (1.0eq) and raw material B (1.0eq) in toluene, ethanol and water (Vtol:V:V=3:0.5-1.5:0.5-1.5) Add tetrakistriphenylphosphine palladium (0.005-0.015eq) and potassium carbonate (1.5-2.5eq) to the mixed solution, stir evenly, heat up to 90±2°C, and reflux for 4-6 hours, after the solution is cooled to room temperature , retain the organic phase, and then extract the aqueous phase with ethyl acetate; after combining the organic phases, use anhydrous magnesium sulfate to dry, and use a rotary evaporator to remove the solvent to obtain a solid organic matter; recrystallize in toluene, filter, and The filter cake was rinsed with petroleum ether and dried in an oven at 65±2°C for 10-14 hours to obtain Intermediate 1.

[0049] S2. Under the protec...

Embodiment 1

[0054] This embodiment provides a capping layer material, and its preparation method is as follows:

[0055] step 1:

[0056]

[0057] Under nitrogen protection, raw material A-6 (30.00mmol) and raw material B-6 (30.00mmol) were dissolved in a mixed solution of 220.00ml toluene, ethanol and water (Vtol:V:V=3:1:1), Add tetrakistriphenylphosphine palladium (0.30mmol) and potassium carbonate (60.00mmol), stir evenly, raise the temperature to 90°C, and reflux for 5 hours. After the solution is cooled to room temperature, keep the organic phase, and then extract the water with ethyl acetate phase; after combining the organic phases, drying was performed using anhydrous magnesium sulfate, and the solvent was removed using a rotary evaporator to obtain solid organic matter. Place it in toluene for recrystallization, filter, rinse the filter cake with petroleum ether, and dry it in a 65°C oven for 12 hours to obtain intermediate 1 (15.98g, yield: 86.43%).

[0058] Step 2:

[005...

Embodiment 2

[0074] This embodiment provides a capping layer material, and its preparation method is as follows:

[0075] step 1:

[0076]

[0077] Under nitrogen protection, raw material A-15 (30.00mmol) and raw material B-15 (30.00mmol) were dissolved in a mixed solution of 220.00ml toluene, ethanol and water (Vtol:V:V=3:1:1), Add tetrakistriphenylphosphine palladium (0.30mmol) and potassium carbonate (60.00mmol), stir evenly, raise the temperature to 90°C, and reflux for 5 hours. After the solution is cooled to room temperature, keep the organic phase, and then extract the water with ethyl acetate phase; after combining the organic phases, drying was performed using anhydrous magnesium sulfate, and the solvent was removed using a rotary evaporator to obtain solid organic matter. Place it in toluene for recrystallization, filter, rinse the filter cake with petroleum ether, and dry it in a 65°C oven for 12 hours to obtain intermediate 1 (14.37g, yield: 86.41%).

[0078] Step 2:

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com