Prednisone acetate micro-tablet and preparation method thereof

A technology of prednisone acetate and microtablets, which is applied in the direction of medical formulas, medical preparations containing no active ingredients, medical preparations containing active ingredients, etc., and can solve the problems of slow dissolution of prednisone acetate tablets, relatively large dose differences, Problems such as difficulty in medication for patients, to achieve the effect of solving the slow dissolution rate of tablets, reducing the loss of raw materials, and strong controllability of the method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

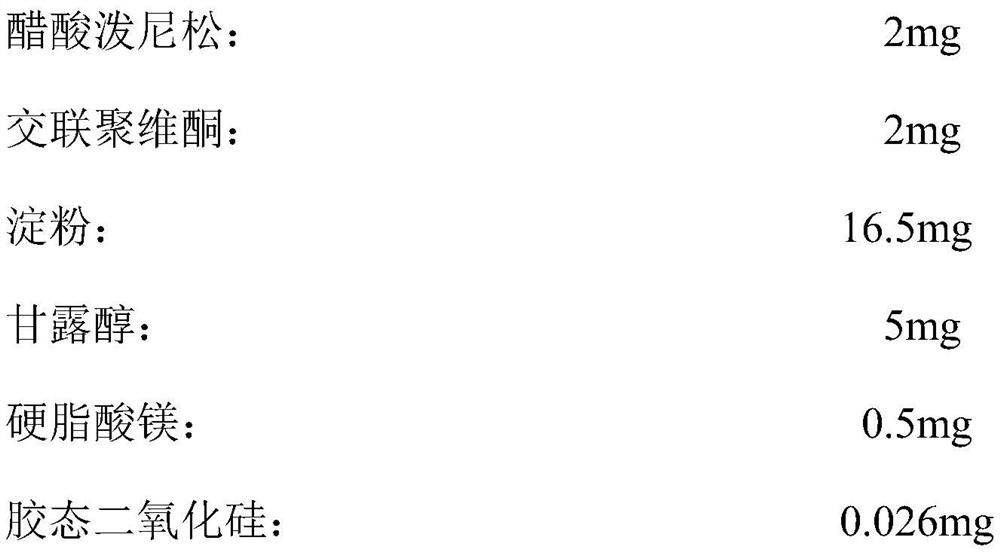

[0033] Composition of prednisone acetate microtablets:

[0034]

[0035] The preparation method of prednisone acetate microchips:

[0036] (1) Pretreatment of raw and auxiliary materials: mix prednisone acetate and starch at a ratio of 1:2 and then pulverize. Starch and other auxiliary materials are passed through a 40-mesh sieve, and auxiliary materials that cannot be sieved are crushed and sieved;

[0037] (2) Pre-mixing: put the pre-treated mixed powder in the prescribed amount, the remaining starch and the prescribed amount of crospovidone and mannitol in a mixer and mix for 20 minutes;

[0038] (3) Granulation: use an appropriate amount of 50% ethanol solution to obtain a soft material with suitable hardness, use a 20-mesh sieve to granulate, dry at 60°C, and measure the moisture to be 5.1%;

[0039] (4) Total blending: the obtained granules were mixed with colloidal silicon dioxide for 3 minutes, then the prescription amount of magnesium stearate was added and mixed...

Embodiment 2

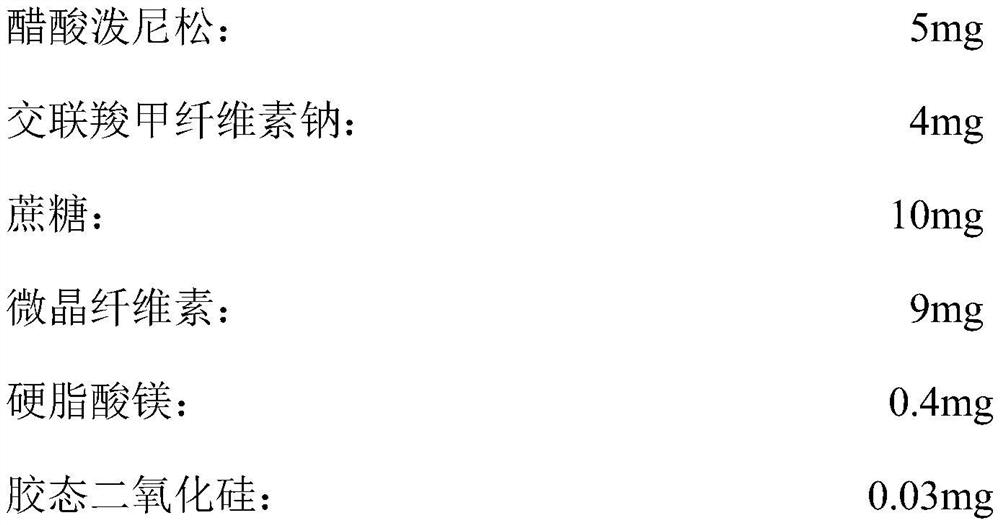

[0042] Composition of prednisone acetate microtablets:

[0043]

[0044] The preparation method of prednisone acetate microchips:

[0045] (1) Pretreatment of raw and auxiliary materials: mix prednisone acetate and sucrose at a ratio of 1:2 and then pulverize. Starch and other auxiliary materials are passed through a 40-mesh sieve, and auxiliary materials that cannot be sieved are crushed and sieved;

[0046] (2) Premixing: put the pretreated obtained recipe amount mixed powder, recipe amount croscarmellose sodium, and microcrystalline cellulose in a mixer and mix for 20 minutes;

[0047] (3) Granulation: use an appropriate amount of 50% ethanol solution to obtain a soft material with suitable hardness, use a 20-mesh sieve to granulate, dry at 60°C, and the measured moisture content is 5.4%;

[0048] (4) Total blending: the obtained granules were mixed with colloidal silicon dioxide for 3 minutes, then the prescription amount of magnesium stearate was added and mixed for ...

Embodiment 3

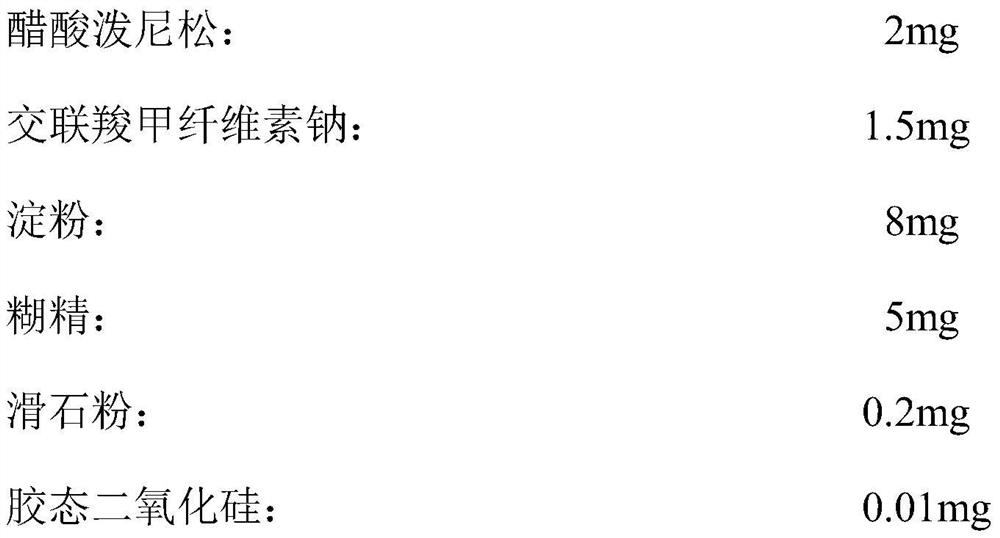

[0051] Composition of prednisone acetate microtablets:

[0052]

[0053]Preparation Process:

[0054] (1) Pretreatment of raw and auxiliary materials: mix prednisone acetate and starch at a ratio of 1:1 and then pulverize. Starch and other auxiliary materials are passed through a 40-mesh sieve, and auxiliary materials that cannot be sieved are crushed and sieved;

[0055] (2) Pre-mixing: put the pretreated mixed powder in the prescribed amount, the remaining starch, the prescribed amount of croscarmellose sodium, and dextrin in a mixer and mix for 30 minutes;

[0056] (3) Granulation: use an appropriate amount of 50% ethanol solution to obtain a soft material with suitable hardness, use a 20-mesh sieve to granulate, dry at 60°C, and measure the water content to be 4.6%;

[0057] (4) Total blending: the obtained granules are mixed with colloidal silicon dioxide for 2 minutes, then the prescription amount of magnesium stearate is added and mixed for 2 minutes;

[0058] (5)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com