Organic-solvent-free combined extraction method of thyme essential oil and thyme total flavonoids

An organic solvent and combined extraction technology, which is applied in the direction of essential oils/fragrances, anti-toxic agents, drug combinations, etc., can solve the problems of easy oxidation of thyme essential oil, lower volatility, lower yield, etc., achieve short preparation time and reduce the total amount , the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

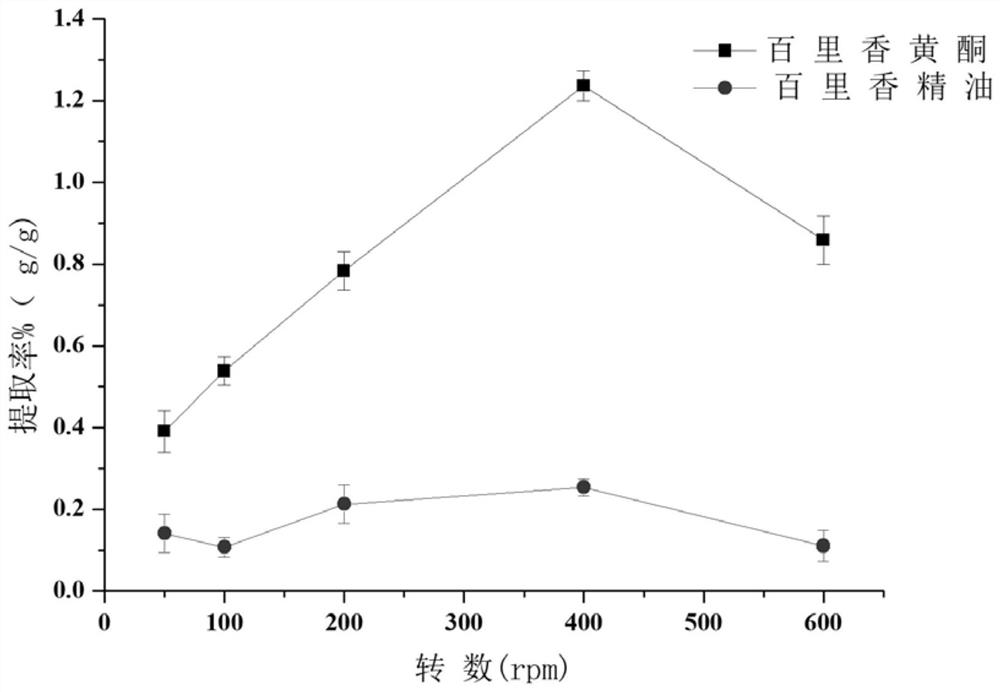

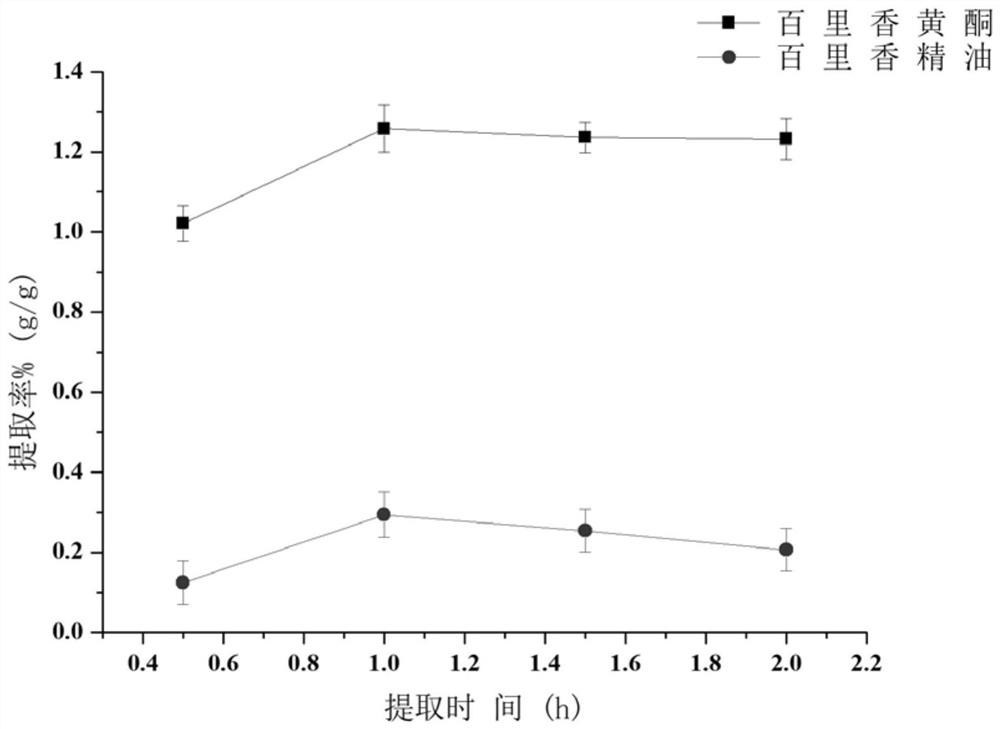

Embodiment 1

[0028] Add thyme powder (50.0g) and sodium hydroxide (5g) in the 200mL stainless steel ball mill jar, then add stainless steel ball mill beads as the grinding medium, the diameter of the ball mill beads is 10mm, and the control filling rate is 58% ((ball volume × ball number) / the total volume of the ball milling tank), after mixing evenly, put the ball milling tank into the planetary ball mill, set the rotating speed to 400rpm, and the time is 1.5 hours. After the ball milling, take out the powder, put the powder in a beaker, add 200mL petroleum ether and stir at room temperature After extracting for 5 minutes and filtering, concentrate the filtrate under reduced pressure at 35°C to constant weight, which is thyme essential oil, and accurately record the quality of the oily liquid; Wash the filter cake with 50 mL of deionized water. Combine the filtrates and concentrate to 50mL, slowly add 8.20g of citric acid to completely neutralize and filter, the obtained solid is the tot...

Embodiment 2

[0030]Add thyme powder (50.0g) and sodium carbonate (5g) in the 200mL stainless steel ball mill jar, then add stainless steel ball mill beads as the grinding medium, the diameter of the ball mill beads is 10mm, and the control filling rate is 58% ((ball volume × ball number) / The total volume of the ball milling tank), after mixing evenly, put the ball milling tank into the planetary ball mill, set the rotation speed to 400rpm, and the time is 1.5 hours. After the ball milling, take out the powder, put the powder in a beaker, add 200mL petroleum ether and stir at room temperature to extract After 5 minutes of filtration, concentrate the filtrate under reduced pressure at 40°C to constant weight, which is the thyme essential oil. Accurately record the quality of the oily liquid; after the filter residue is evaporated, add 500mL of deionized water and stir for 5 minutes at room temperature, and filter to obtain a clear filtrate and use Wash the filter cake with 50 mL of deionized...

Embodiment 3

[0032] Add thyme powder (50.0g) and sodium bicarbonate (5g) in the 200mL stainless steel ball mill jar, then add stainless steel ball mill beads as the grinding medium, the diameter of the ball mill beads is 10mm, and the control filling rate is 58% ((ball volume × ball number) / the total volume of the ball milling tank), after mixing evenly, put the ball milling tank into the planetary ball mill, set the rotating speed to 400rpm, and the time is 1.5 hours. After the ball milling, take out the powder, put the powder in a beaker, add 200mL petroleum ether and stir at room temperature After extraction for 5 minutes and filtration, concentrate the filtrate under reduced pressure at 40°C to constant weight, which is the thyme essential oil. Accurately record the quality of the oily liquid; after the filter residue is evaporated, add 500mL deionized water and stir for extraction at room temperature for 5 minutes, and filter to obtain a clear filtrate And wash the filter cake with 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com