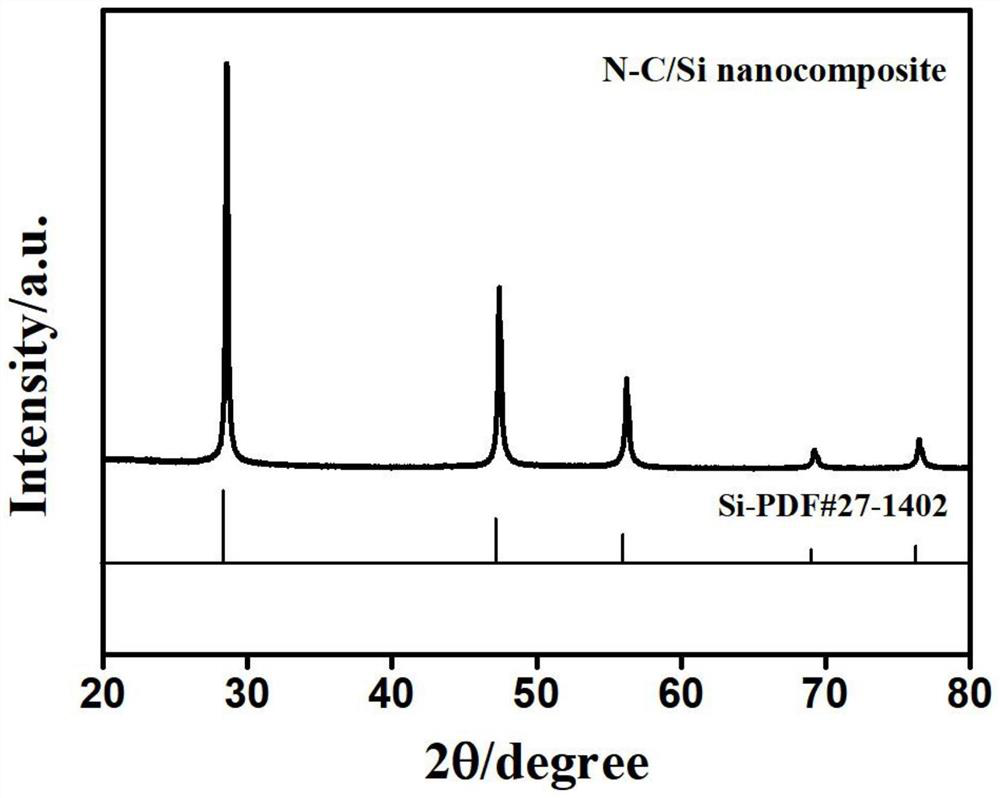

Preparation method and application of nitrogen-doped carbon/silicon nano composite material

A technology of nitrogen-doped carbon and composite materials, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of limited large-scale preparation, complicated preparation process, and poor product consistency. Achieve the effects of reducing energy consumption and labor costs, simplifying experimental steps, and excellent material performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

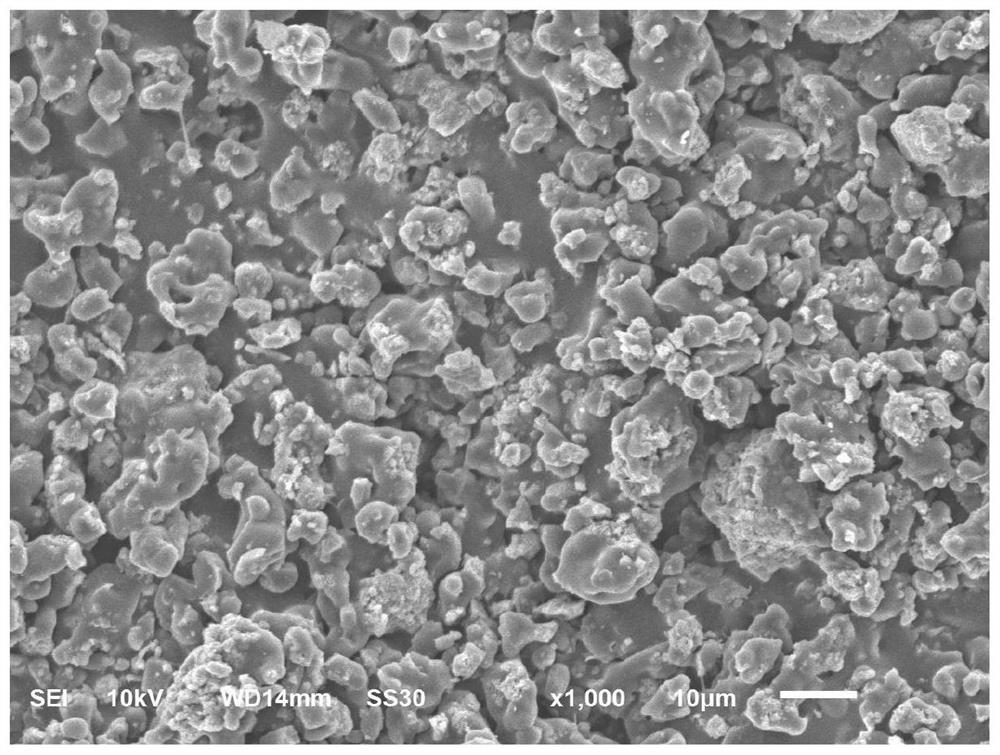

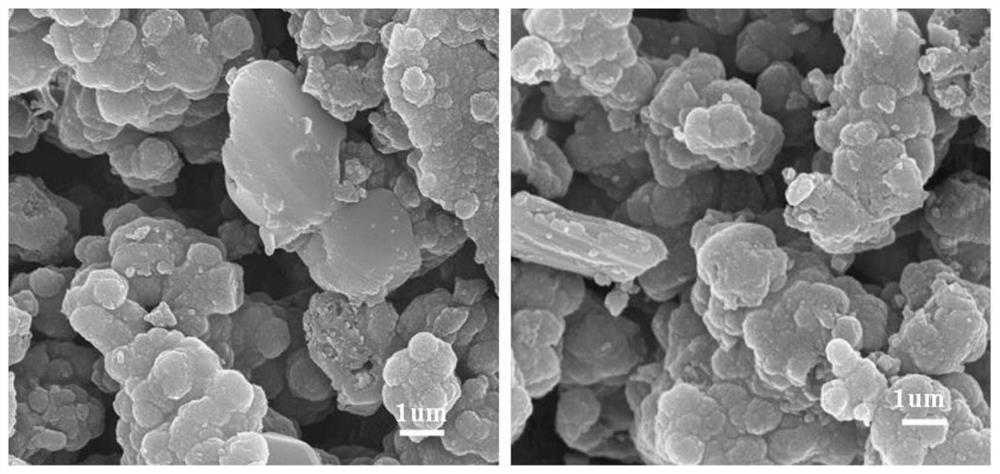

[0037] Embodiment 1: a kind of preparation method of nitrogen-doped carbon / silicon nanocomposite material, comprises the steps:

[0038] 1) Ball mill silicon powder (40-100 μm) at a ball-to-material ratio of 40:1 at 500 rpm for 12 hours;

[0039] 2) Disperse 0.5g of silicon powder after ball milling in step 1) into 80mL of deionized water, disperse with 400W ultrasonic wave for 2h to obtain a dispersion, then add 4.5g of acrylic acid, 1.5g of melamine and 0.10g of dodecylbenzene to the dispersion Sodium sulfonate, and stirred for 3h; then add 2mL ammonium persulfate aqueous solution with a mass percentage of 5%, and stir to obtain a mixed solution, then transfer the mixed solution to a large crucible, stir evenly, and then put the large crucible into In a small mobile muffle furnace, under air conditions, the temperature was raised to 80°C at a heating rate of 5°C / min for a polymerization reaction, and the temperature was kept for 3 hours to obtain a polymer / silicon composite ...

Embodiment 2

[0043] Embodiment 2: a kind of preparation method of nitrogen-doped carbon / silicon nanocomposite material, comprises the following steps:

[0044] 1) Ball mill silicon powder (40-100 μm) at a ball-to-material ratio of 40:1 at 500 rpm for 12 hours;

[0045] 2) Disperse 0.5g of silicon powder after ball milling in step 1) into 80mL of deionized water, disperse with 400W ultrasonic wave for 2h to obtain a dispersion, and then add 5.0g of acrylic acid, 1.0g of urea and 0.12g of dodecylbenzene to the dispersion Sodium sulfonate, and stirred for 3h; then add 2mL ammonium persulfate aqueous solution with a mass percentage of 5%, and stir to obtain a mixed solution, then transfer the mixed solution to a large crucible, stir evenly, and then put the large crucible into In a small mobile muffle furnace, under air conditions, the temperature was raised to 80°C at a heating rate of 5°C / min for a polymerization reaction, and the temperature was kept for 3 hours to obtain a polymer / silicon ...

Embodiment 3

[0047] Embodiment 3: a kind of preparation method of nitrogen-doped carbon / silicon nanocomposite material, comprises the steps:

[0048] 1) Ball mill silicon powder (40-100 μm) at a ball-to-material ratio of 40:1 at 500 rpm for 12 hours;

[0049] 2) Disperse 0.5g of silicon powder after ball milling in step 1 into 80mL of deionized water, disperse with 400W ultrasonic for 2h to obtain a dispersion, then add 20.0g of acrylic acid, 5.0g of melamine and 0.15g of dodecylbenzene to the dispersion Sodium sulfonate, and stirred for 3h; then add 2mL ammonium persulfate aqueous solution with a mass percentage of 5%, and stir to obtain a mixed solution, then transfer the mixed solution to a large crucible, stir evenly, and then put the large crucible into In a small mobile muffle furnace, under air conditions, the temperature was raised to 80°C at a heating rate of 5°C / min for a polymerization reaction, and the temperature was kept for 3 hours to obtain a polymer / silicon composite mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com