Plastic degradation agent for alkaline soil remediation and preparation method thereof

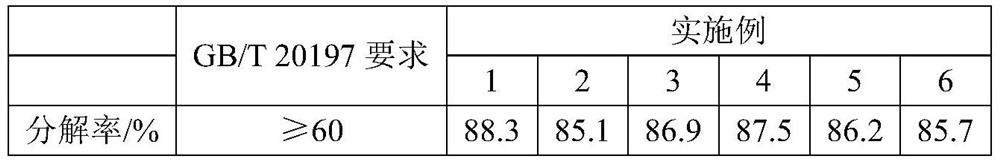

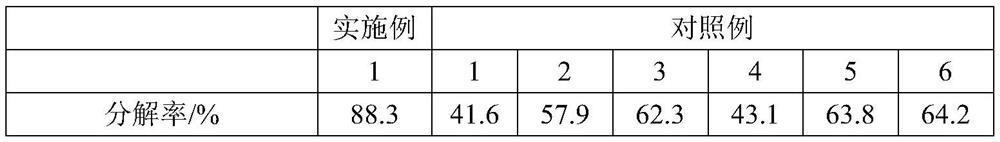

A technology of soil remediation and degradation agent, which is applied in the field of plastic degradation agent for alkaline soil remediation and its preparation, which can solve the problems of indigestion and degradation of waste plastics, destruction of soil ecosystem, soil compaction, etc., and achieve excellent water absorption and safety and environmental protection , Improve the degradation efficiency and the effect of increasing the degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A kind of plastic degradation agent for alkaline soil restoration, its preparation method comprises the following steps:

[0020] (1), 6 parts of extracellular hydrolase, 2.6 parts of dioxygenase, 3.8 parts of monooxygenase, 4.6 parts of oxidoreductase, 1.8 parts of bone enzyme, 2.3 parts of fatty acid oxidase, 0.08 part of carbo resin, 4.5 parts 1 part of bone meal and 66 parts of water were added to the reaction kettle, and the reaction was carried out for 45 minutes while maintaining the mixing temperature of the system at 30°C. The product was spray-dried to obtain an enzyme preparation;

[0021] (2), 12 parts of 2-acrylamide-2-methylpropanesulfonic acid, 5.5 parts of acrylic acid, 5.3 parts of butyl acrylate, 1.8 parts of vinyl acetate, 43 parts of water, 30 parts of ethanol, 0.18 parts of 819 photoinitiator and 7.8 parts of Sr-10 emulsifier were added to the reaction kettle, the stirring speed was 360r / min, and the reaction temperature was 33°C for 43 minutes. The...

Embodiment 2

[0025] A kind of plastic degradation agent for alkaline soil restoration, its preparation method comprises the following steps:

[0026] (1), 6 parts of extracellular hydrolase, 2 parts of dioxygenase, 2 parts of monooxygenase, 1 part of oxidoreductase, 1 part of bone enzyme, 1 part of fatty acid oxidase, 0.05 part of carbo resin, 3 parts of 1 part of bone powder and 51 parts of water were added to the reaction kettle, and the reaction was carried out at a temperature of 30°C for 45 minutes, and the product was spray-dried to obtain an enzyme preparation;

[0027] (2), 12 parts of 2-acrylamide-2-methylpropanesulfonic acid, 2 parts of acrylic acid, 1 part of butyl acrylate, 0.5 part of vinyl acetate, 39 parts of water, 12 parts of ethanol, 0.03 part of 819 photoinitiator and 3 parts of Sr-10 emulsifier were added to the reaction kettle, the stirring speed was 360r / min, and the reaction temperature was 33°C for 43min. The product was exposed to 100W high-pressure mercury lamp fo...

Embodiment 3

[0031] A kind of plastic degradation agent for alkaline soil restoration, its preparation method comprises the following steps:

[0032] (1), with 6 parts of extracellular hydrolase, 5 parts of dioxygenase, 7 parts of monooxygenase, 8 parts of oxidoreductase, 4 parts of bone enzyme, 5 parts of fatty acid oxidase, 0.8 part of carbo resin, 6 parts of 1 part of bone powder and 76 parts of water were added to the reaction kettle, and the reaction was carried out for 45 minutes while maintaining the mixing temperature of the system at 30°C, and the product was spray-dried to obtain an enzyme preparation;

[0033] (2), 12 parts of 2-acrylamide-2-methylpropanesulfonic acid, 7 parts of acrylic acid, 6 parts of butyl acrylate, 4 parts of vinyl acetate, 51 parts of water, 36 parts of ethanol, 0.3 part of 819 photoinitiator and 9 parts of Sr-10 emulsifier were added to the reaction kettle, the stirring speed was 360r / min, and the reaction temperature was 33°C for 43min. The product was e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com