Nitrogen and sulfur co-doped carbon fiber grafted polythiophene/MnS composite material and preparation method of electrode thereof

A technology of nitrogen-sulfur co-doping and composite materials, which is applied in the field of composite materials and electrochemistry, and can solve the problems of large shrinkage and expansion of conductive polymers, poor cycle stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

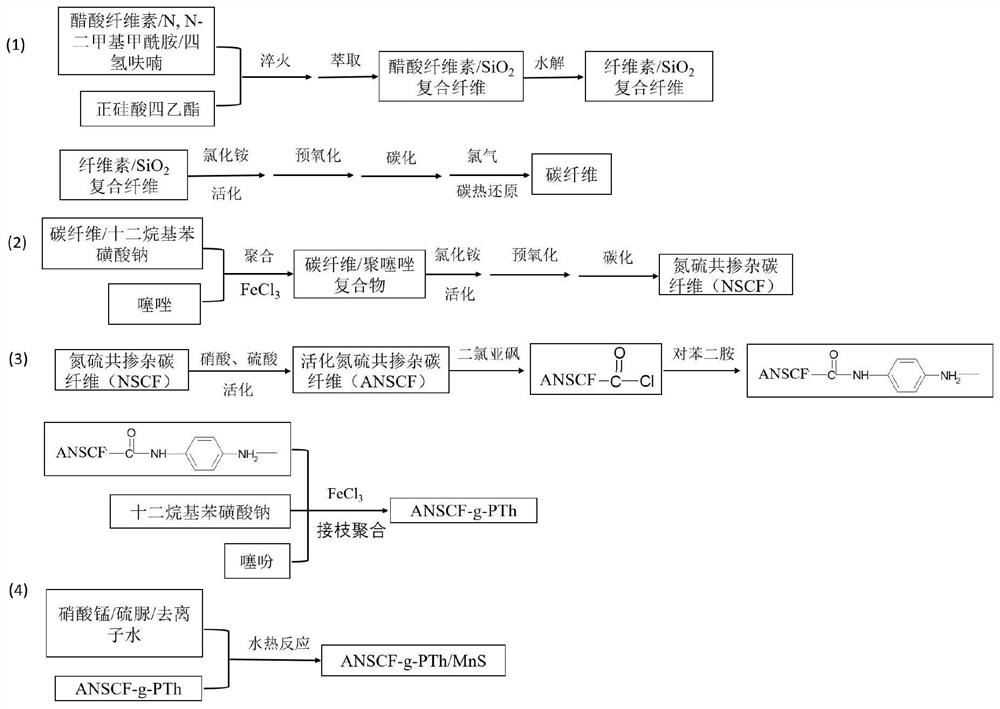

[0043] This embodiment relates to a preparation method of a nitrogen-sulfur co-doped carbon fiber grafted polythiophene / MnS composite electrode, such as figure 1 As shown, it specifically includes the following steps:

[0044] 1) Preparation of carbon fiber

[0045] Dissolve 2.8g of cellulose acetate (CA) in a mixed solvent of 30g of N,N-dimethylformamide and 20g of tetrahydrofuran, and stir magnetically at 50°C for 5h to form a solution. 0.8 g of tetraethyl orthosilicate was added dropwise into the solution, and the stirring was continued for 2 h to obtain a precursor quenching solution. After quenching the precursor quenching solution at -10°C for 100 minutes, take it out and soak it in distilled water to remove the mixed solvent, and change the distilled water once every 8 hours, and change the distilled water 3 times. After washing and drying, CA / SiO 2 Composite fibers. CA / SiO 2 The composite fiber was soaked in 0.1mol / L NaOH ethanol solution for 24h to convert CA int...

Embodiment 2

[0054] This embodiment relates to a preparation method of a nitrogen-sulfur co-doped carbon fiber grafted polythiophene / MnS composite electrode, which specifically includes the following steps:

[0055] 1) Preparation of carbon fiber

[0056] Dissolve 3.5g of cellulose acetate (CA) in a mixed solvent of 40g of N,N-dimethylformamide and 25g of tetrahydrofuran, and stir magnetically at 50°C for 5h to form a solution. 1.2 g of tetraethyl orthosilicate was added dropwise into the solution, and the stirring was continued for 2 h to obtain a precursor quenching solution. After quenching the precursor quenching solution at -25°C for 80 minutes, take it out and soak it in distilled water to remove the mixed solvent, change the distilled water once every 8 hours, and change the distilled water 3 times. After washing and drying, CA / SiO 2 Composite fibers. CA / SiO 2 The composite fiber was soaked in 0.1mol / L NaOH ethanol solution for 24h to convert CA into cellulose, washed with disti...

Embodiment 3

[0065] This embodiment relates to a preparation method of a nitrogen-sulfur co-doped carbon fiber grafted polythiophene / MnS composite electrode, which specifically includes the following steps:

[0066] 1) Preparation of carbon fiber

[0067] Dissolve 4g of cellulose acetate (CA) in a mixed solvent of 60g of N,N-dimethylformamide and 20g of tetrahydrofuran, and stir magnetically at 50°C for 5h to form a solution. Add 1 g of tetraethyl orthosilicate dropwise into the solution, and continue stirring for 2 h to obtain a precursor quenching solution. After quenching the precursor quenching solution at -15°C for 110 minutes, take it out and soak it in distilled water to remove the mixed solvent, and change the distilled water once every 8 hours, and change the distilled water 3 times. After washing and drying, CA / SiO 2 Composite fibers. CA / SiO 2 The composite fiber was soaked in 0.1mol / L NaOH ethanol solution for 24h to convert CA into cellulose, washed with distilled water and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com