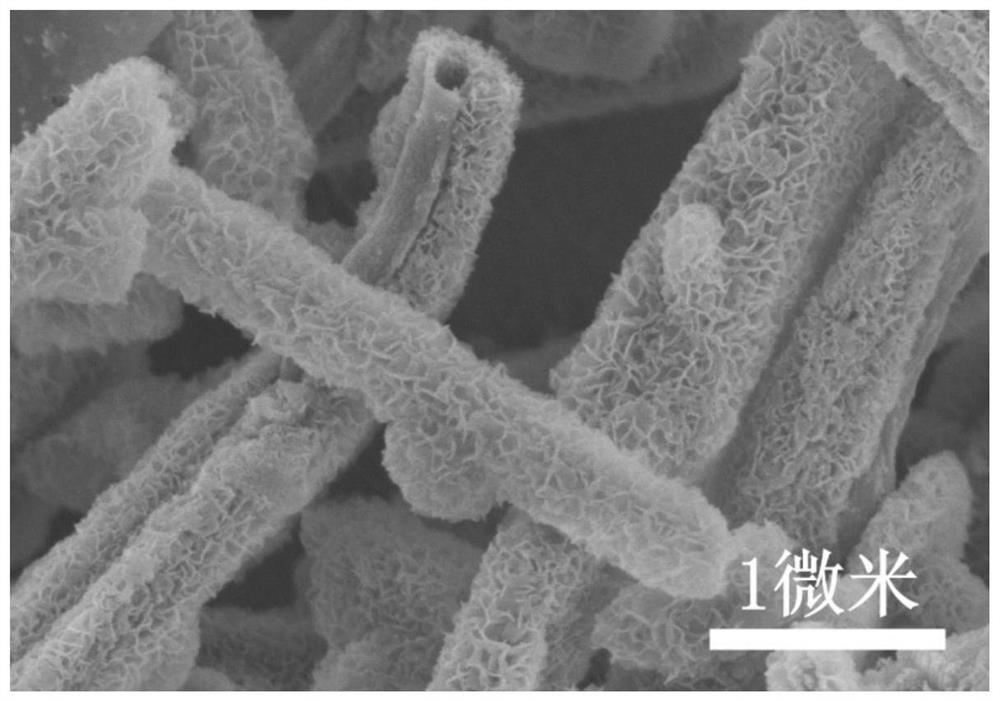

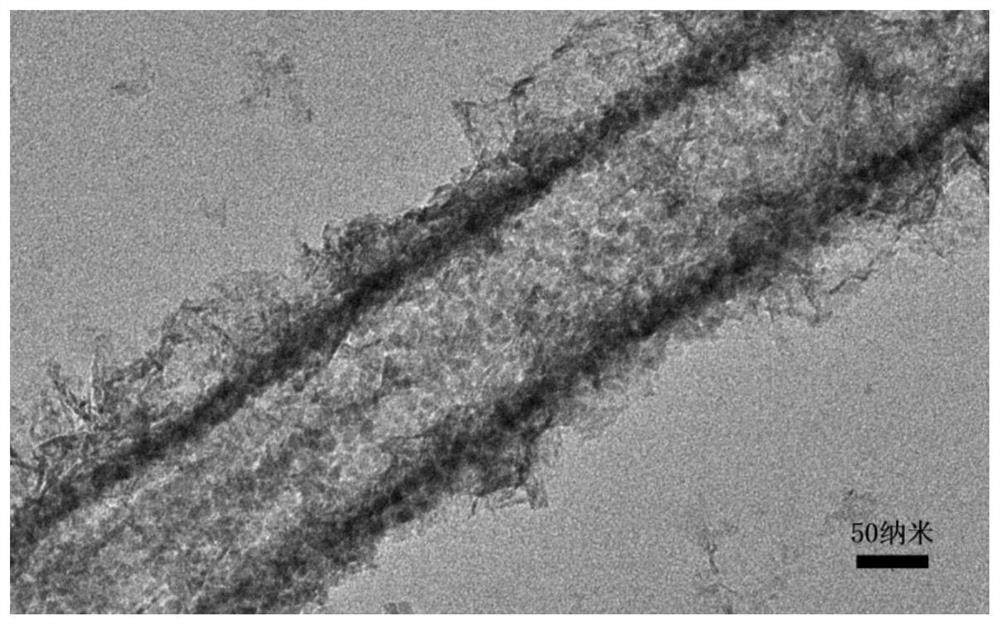

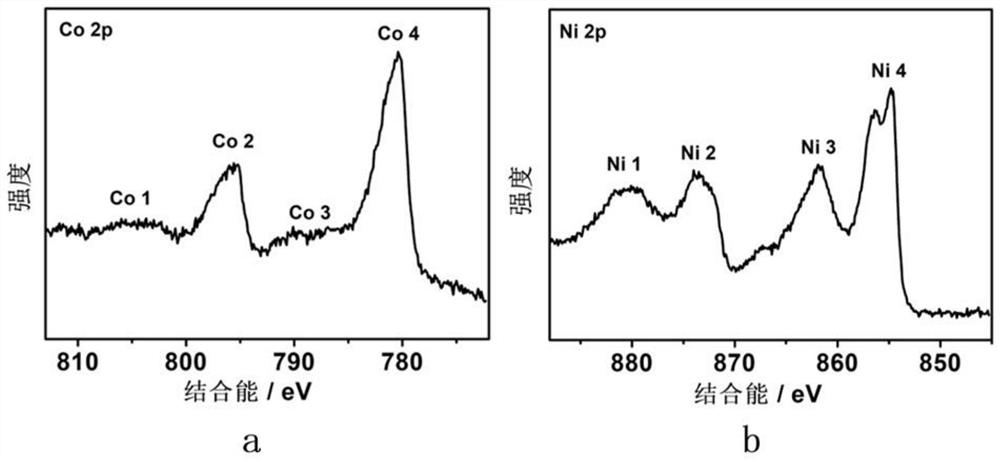

Cobaltosic oxide-nickel oxide double-layer mesoporous nanotube composite material as well as preparation method and application thereof

A technology of tricobalt tetroxide and composite materials, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, nanotechnology, etc., can solve problems such as hindering electron/mass transfer and internal material utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Step 1: Weigh 0.873g cobalt nitrate hexahydrate, 0.3993g L-aspartic acid in a 50mL polytetrafluoroethylene-lined stainless steel hydrothermal reaction kettle, and add 10mL deionized water and 18mL ethylene glycol to it, Add 3mL, 2mol / L sodium hydroxide solution under magnetic stirring, and stir magnetically at room temperature until the solution turns transparent reddish brown. Then transfer the reaction kettle to a 180°C electric blast drying oven and keep it for 5 hours. After the end, the pink solid is collected by centrifugation, and then washed with water and ethanol for four times, and finally placed in a vacuum drying oven at 40°C. Drying for 12 hours under the hood to obtain Co-Asp nanowires.

[0042] Step 2: Weigh 0.075 g of Co-Asp nanowires into a 100 mL beaker, add 20 mL of absolute ethanol therein, and stir to disperse the Co-Asp nanowires.

[0043] Step 3: Add 10mL (0.1mol L -1 ) ethanol solution of nickel nitrate hexahydrate, after mixing evenly, transfe...

Embodiment 2

[0046] Step 1: Weigh 1.746g cobalt nitrate hexahydrate, 0.7986g L-aspartic acid in a 50mL polytetrafluoroethylene-lined stainless steel hydrothermal reaction kettle, and add 10mL deionized water and 18mL ethylene glycol to it, Add 6 mL of 2 mol / L sodium hydroxide solution under magnetic stirring, and stir magnetically at room temperature until the solution turns transparent reddish brown. Then transfer the reaction kettle to a 180°C electric blast drying oven and keep it for 5 hours. After the end, the pink solid is collected by centrifugation, and then washed with water and ethanol for four times, and finally placed in a vacuum drying oven at 40°C. Drying for 12 hours under the hood to obtain Co-Asp nanowires.

[0047] Step 2: Weigh 0.075 g of Co-Asp nanowires into a 100 mL beaker, add 20 mL of absolute ethanol therein, and stir to disperse the Co-Asp nanowires.

[0048] Step 3: Add 10mL (0.1mol L -1 ) ethanol solution of nickel nitrate hexahydrate, after mixing evenly, tra...

Embodiment 3

[0051] Step 1: Weigh 0.873g cobalt nitrate hexahydrate, 0.3993g L-aspartic acid in a 50mL polytetrafluoroethylene-lined stainless steel hydrothermal reaction kettle, and add 10mL deionized water and 18mL ethylene glycol to it, Add 3mL, 2mol / L sodium hydroxide solution under magnetic stirring, and stir magnetically at room temperature until the solution turns transparent reddish brown. Then transfer the reaction kettle to a 180°C electric blast drying oven and keep it for 5 hours. After the end, the pink solid is collected by centrifugation, and then washed with water and ethanol for four times, and finally placed in a vacuum drying oven at 40°C. Drying for 12 hours under the hood to obtain Co-Asp nanowires.

[0052] Step 2: Weigh 0.150 g of Co-Asp nanowires into a 100 mL beaker, add 20 mL of absolute ethanol therein, and stir to disperse the Co-Asp nanowires.

[0053] Step 3: Add 20mL (0.1mol L -1 ) ethanol solution of nickel nitrate hexahydrate, after mixing evenly, transfe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com