Yellow-light carbon dot with high light and heat stability and preparation of yellow-light carbon dot

A technology of thermal stability and yellow light, applied in the field of fluorescent light-emitting materials, can solve the problem that the crystallinity needs to be further improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

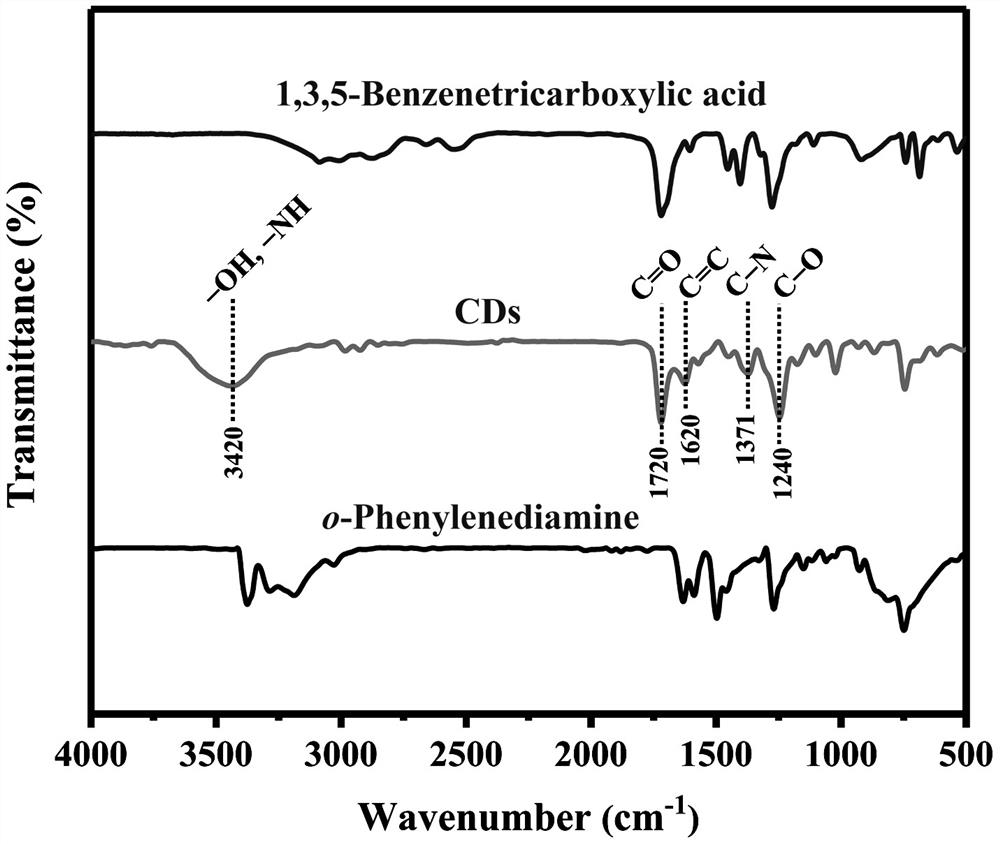

[0039] Weigh 0.42g of trimesic acid and 0.21g of o-phenylenediamine, add them into 30mL of absolute ethanol, ultrasonically dissolve them evenly, place them in a 100mL reaction kettle, and conduct solvothermal reaction in an oven at 200°C for 10h. After the reaction was completed, air-cooled to room temperature to obtain a brown carbon dot solution.

[0040] Take out the above-mentioned carbon dot solution, filter it with a 0.22 μm filter membrane, place the filtrate in a 500 Da dialysis bag, and perform dialysis treatment in absolute ethanol for 48 hours, during which the absolute ethanol is replaced every 8 hours to remove the fluorescent light in the filtrate. Molecules and other impurities are prepared to prepare yellow carbon dots with high photothermal stability.

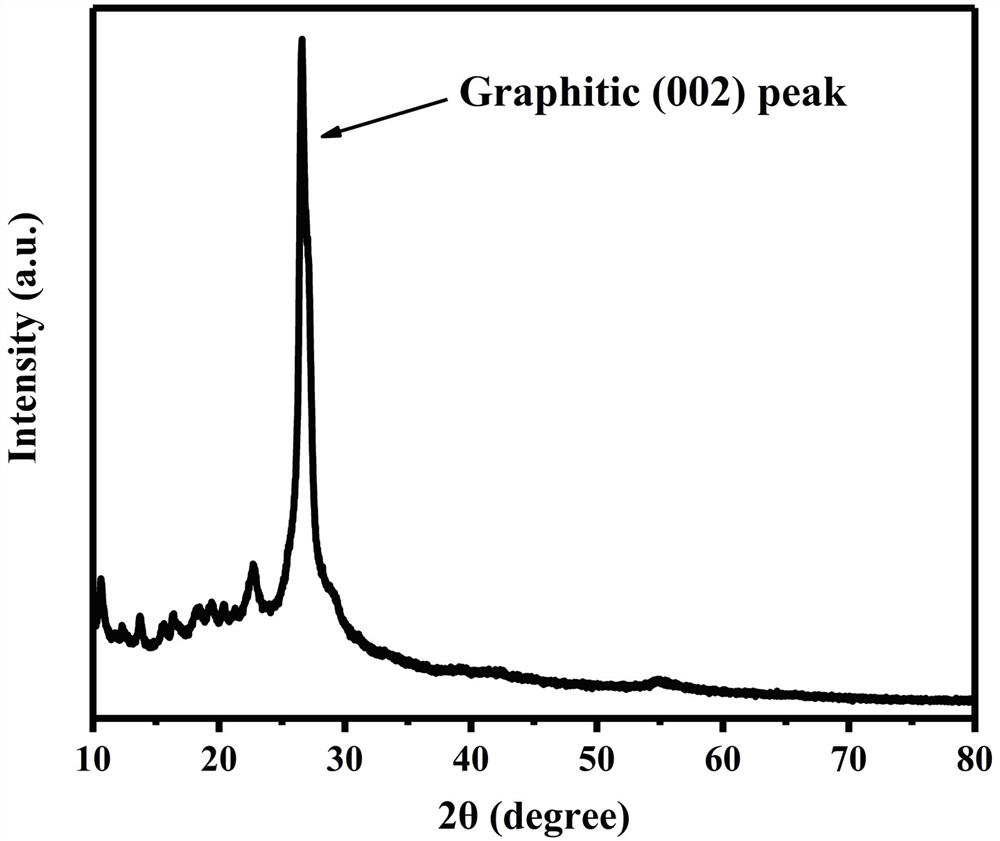

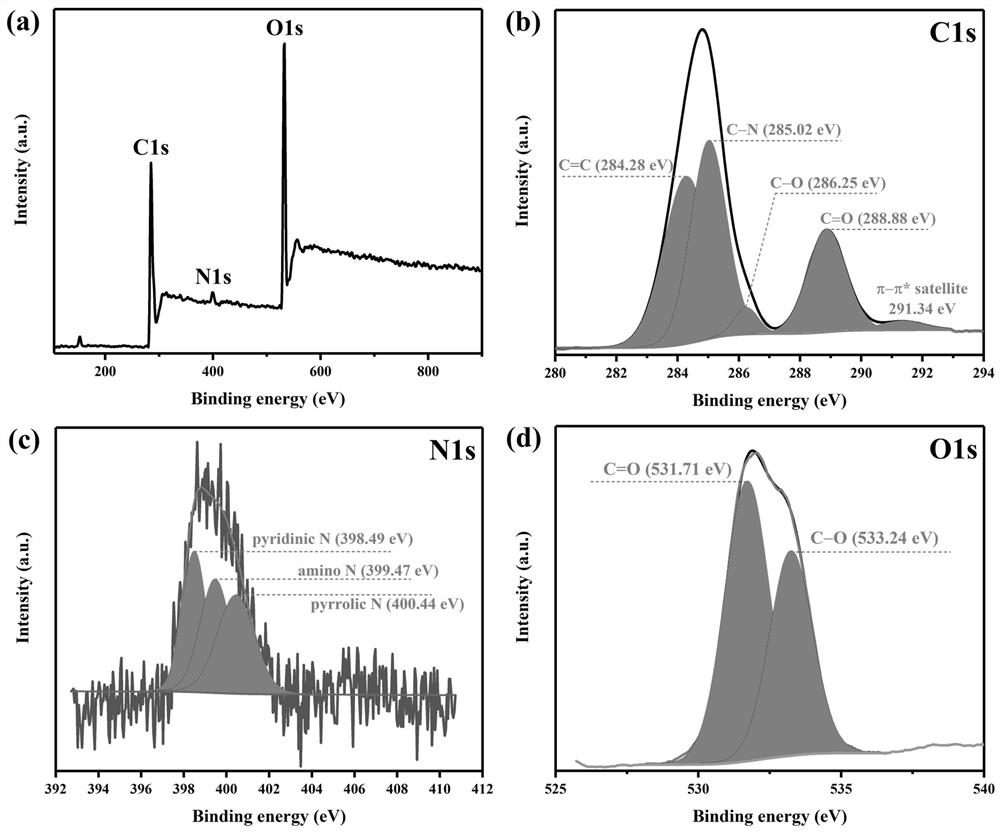

[0041] In this example, the morphology, structure and particle size distribution of the prepared yellow carbon dots were firstly characterized by TEM. The appearance of yellow carbon dots is as follows figu...

Embodiment 2

[0056] Weigh 8mg of the carbon dot solid powder prepared in Example 1, add 1mL of absolute ethanol, after it is fully dissolved, continue to add 1mL of silane coupling agent KH-792 and 0.5mL of deionized water to the solution, ultrasonic 5min, make the solution Mix well to obtain a clear brown solution.

[0057] Add the above solution into a weighing bottle with a specification of 25×25 mm, and put it in an oven at 50° C. for 4 hours to dry.

[0058] After the solution in the weighing bottle became viscous, the solution was added dropwise onto a sapphire glass sheet, and placed in an oven at 60°C, and solidified after 8 hours to form a yellow carbon dot fluorescent film with bright yellow light emission.

[0059] The optical properties of the yellow carbon dot fluorescent film prepared above were investigated under the same conditions. Figure 7 (a) In the emission spectrum of the yellow carbon dot fluorescent film, as the excitation wavelength increases from 365nm to 485nm, ...

Embodiment 3

[0074] Weigh 0.21g of trimesic acid and 0.21g of o-phenylenediamine, add them into 40mL of absolute ethanol, ultrasonically dissolve them evenly, place them in a 100mL reaction kettle, and react in a solvothermal oven at 180°C for 12h. After the reaction was completed, air-cooled to room temperature to obtain a brown carbon dot solution.

[0075] Take out the above-mentioned carbon dot solution, filter it with a 0.22 μm filter membrane, place the filtrate in a dialysis bag of 500 Da, and perform dialysis treatment in absolute ethanol for 42 hours. Molecules and other impurities are prepared to prepare yellow carbon dots with high photothermal stability.

[0076] After the dialysis is finished, the solution in the dialysis bag is taken out and subjected to rotary evaporation treatment to obtain solid carbon dot powder.

[0077] Weigh 10mg of carbon dot solid powder, add 1.2mL of absolute ethanol, after it is fully dissolved, continue to add 1.1mL of silane coupling agent KH-79...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Interplanar spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com