Cu-based flexible non-enzymatic lactic acid sensor electrode film and preparation method thereof

A sensor electrode, flexible technology, applied in the field of Cu-based flexible non-enzyme lactic acid sensor electrode film and its preparation, can solve the problems of inactivation, inability to monitor sweat lactic acid concentration, and affecting the stability of lactic acid sensor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

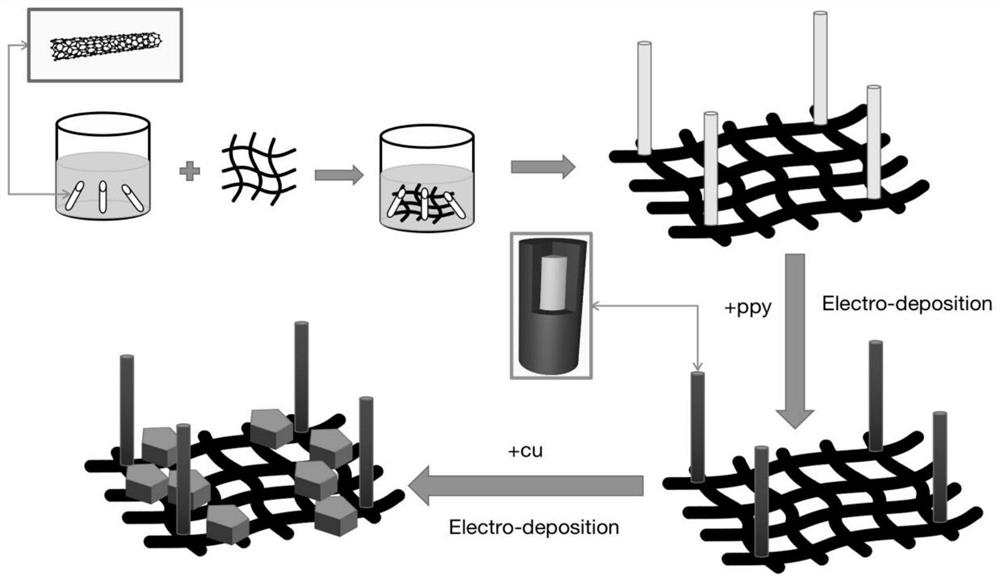

[0034] see figure 1 As shown, the invention provides a kind of preparation method of Cu-based flexible non-enzymatic lactic acid sensor electrode membrane, comprises the steps:

[0035] S1. Preparation of conductive BC / c-MWCNTs nanocomposite membrane: prepare c-MWCNTs suspension with a predetermined concentration; pretreat the BC membrane, and then soak the pretreated BC membrane in the c-MWCNTs suspension for ultrasonic treatment 4 ~6h, take it out and wash it, and prepare the conductive BC / c-MWCNTs nanocomposite film;

[0036] S2, preparation of BC / c-MWCNTs / PPy nanocomposite film: preparing pyrrole monomer solution; clamping the conductive BC / c-MWCNTs nanocomposite film with an electrode clamp as a working electrode, and using a platinum sheet electrode as a counter electrode, A saturated calomel electrode is used as a reference electrode, and the pyrrole monomer solution is used as an electrolyte to carry out electrochemical polymerization reaction, and after the polymeriz...

Embodiment 1

[0047] Embodiment 1 of the present invention provides a method for preparing a Cu-based flexible non-enzymatic lactic acid sensor electrode film, comprising the following steps:

[0048] S1, Preparation of conductive BC / c-MWCNTs nanocomposite film:

[0049] Prepare 100mL uniform suspension of c-MWCNTs (multi-walled carbon nanotubes) with a concentration of 1mg / mL, and a certain amount (9×10 -4 mol L -1 ) cetyl ammonium bromide (CTAB) was mixed with c-MWCNTs uniform suspension to improve its dispersibility, and then ultrasonically dispersed at room temperature for 5 hours through an ultrasonic cleaner with a power of 300W and a frequency of 40kHz to prepare c-MWCNTs suspension.

[0050] Soak the BC membrane in a concentration of 1mol L -1 NaOH solution, treated in a constant temperature water bath at 80°C for 2 hours to remove nutrients and live bacteria, then take out the treated BC membrane and rinse it with deionized water until the pH value is 7; then, clean the treated ...

Embodiment 2 to 6

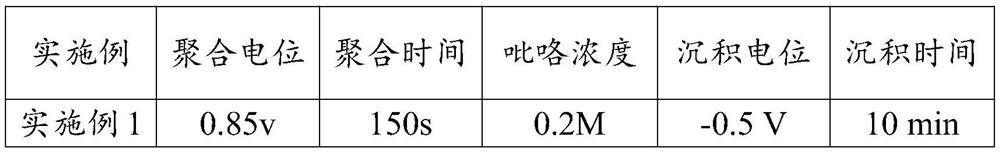

[0063] The difference from Embodiment 1 of the present invention lies in that the process parameter settings in step S2 and step S3 are different, as shown in the table below.

[0064]

[0065]

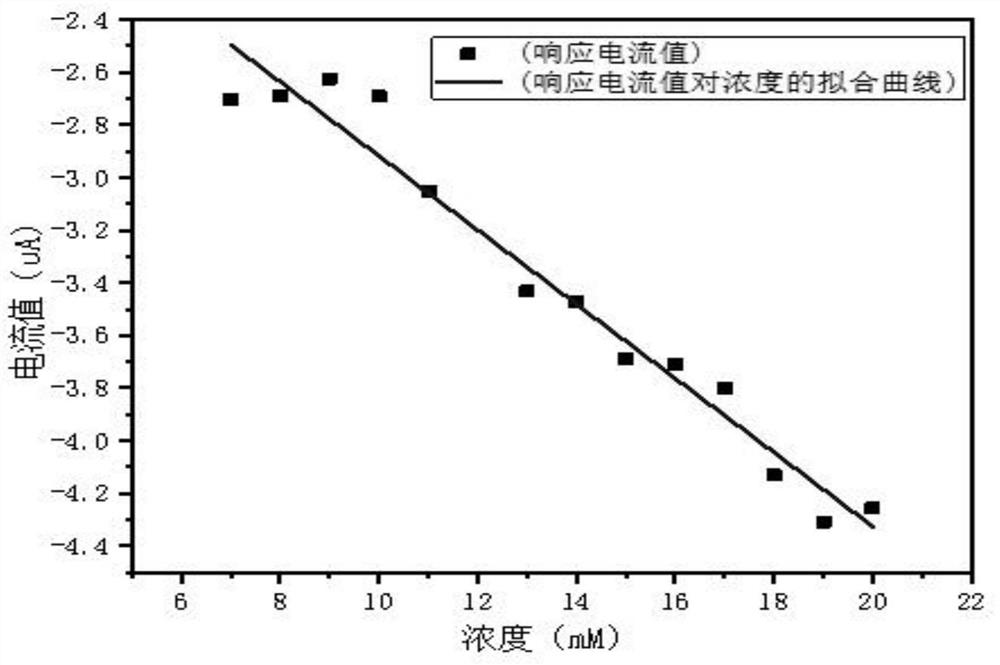

[0066] In conjunction with Table 1, embodiments 1 to 7 are analyzed:

[0067]1) The influence of electrochemical polymerization process settings on the detection range of the prepared Cu-based flexible non-enzymatic lactic acid sensor electrode film is: electrochemical polymerization reactions are mostly carried out within a certain voltage range, and the voltage determines the electrode membrane. The extent and rate at which chemical deposition reactions occur. The higher the voltage, the faster the polymerization reaction and the denser the resulting polymer layer, but if the voltage is too high, the transmission between polymer particles will be hindered and the subsequent reaction will be affected.

[0068] When polymerizing pyrrole, when the polymerization voltage is the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com