Lithium iron manganese phosphate coated single crystal quaternary positive electrode material and preparation method thereof

A technology of lithium iron manganese phosphate and cathode material, applied in the growth of polycrystalline material, positive electrode, single crystal growth, etc., can solve the problems of poor ion conductivity, unable to protect the main material, easy to fall off, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

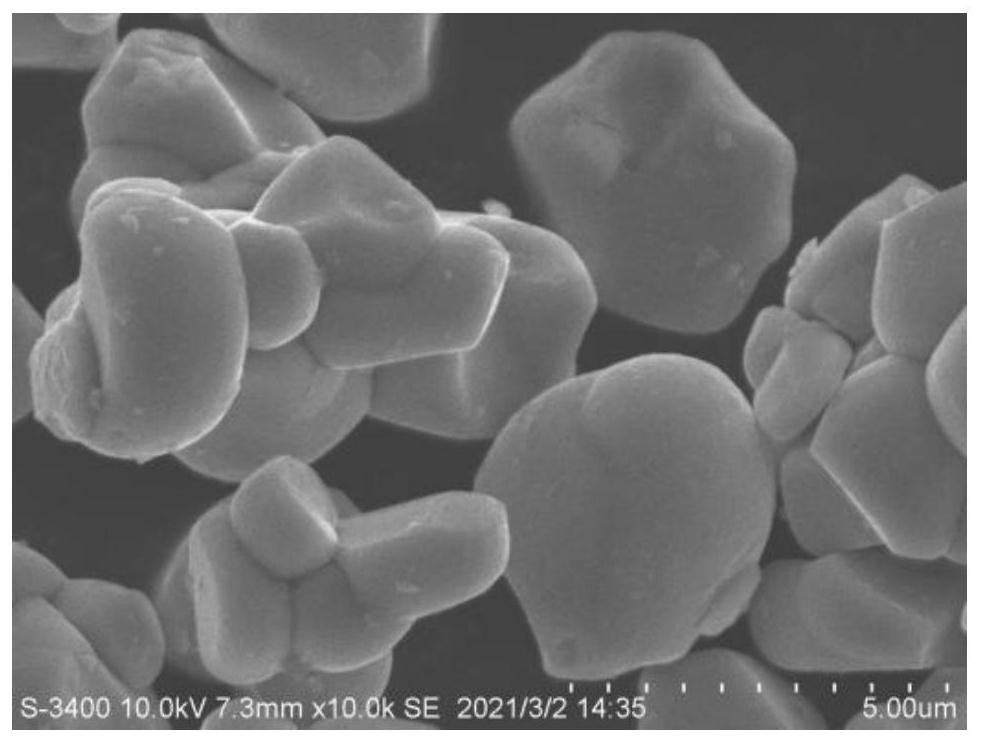

Embodiment 1

[0029] Precursor Ni of cathode material 0.83 mn 0.1 co 0.05 Al 0.02 (OH) 2 , lithium source (LiOH·H 2 O) Dry mixing according to the following ratio: among them, the cathode material quaternary precursor and the lithium source (LiOH·H 2 The Li element in O) is mixed at a molar ratio of 1:1.03, using high-speed mixing equipment, mixing uniformly at a rotating speed of the equipment, mixing time: 20 minutes, rotating speed: 2000rpm, and mixing temperature 25±5°C. The mixed material was sintered at 850° C. for 10 h, and the calcination process was carried out in an oxygen atmosphere (97% concentration), cooled, pulverized and sieved to obtain the first product single crystal quaternary positive electrode material, and the first product was mixed with nano-LiMn 0.8 Fe 0.2 PO 4 According to the mass ratio of 1:1%, the high-speed mixing equipment is used for mixing, and the equipment rotates to mix evenly. The mixing time: 10 minutes, and the rotation speed: 1500rpm. After m...

Embodiment 2

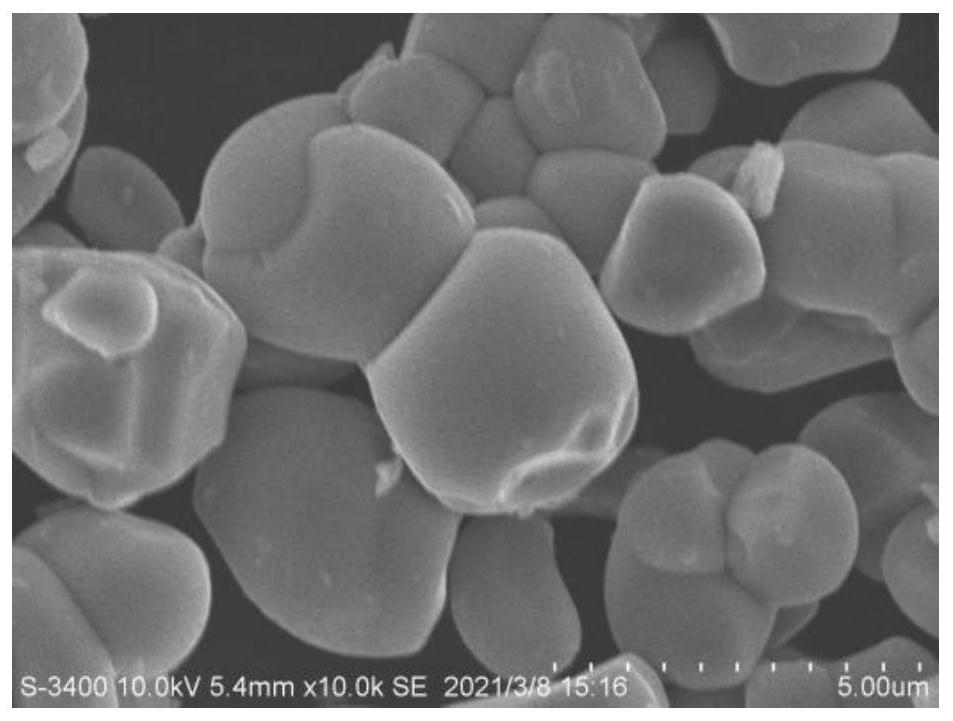

[0031] Precursor Ni of cathode material 0.83 mn 0.1 co 0.05 Al 0.02 (OH) 2 , lithium source (LiOH·H 2 O) Dry mixing according to the following ratio: among them, the cathode material quaternary precursor and the lithium source (LiOH·H 2The Li element in O) is mixed at a molar ratio of 1:1.03, using high-speed mixing equipment, mixing uniformly at a rotating speed of the equipment, mixing time: 20 minutes, rotating speed: 2000rpm, and mixing temperature 25±5°C. The mixed material was sintered at 850° C. for 10 h, and the calcination process was carried out in an oxygen atmosphere (97% concentration), cooled, pulverized and sieved to obtain the first product single crystal quaternary positive electrode material, and the first product was mixed with nano-LiMn 0.8 Fe 0.2 PO 4 According to the mass ratio of 1:3%, the high-speed mixing equipment is used for mixing, and the equipment rotates to mix evenly. The mixing time: 10 minutes, and the rotation speed: 1500rpm. After mi...

Embodiment 3

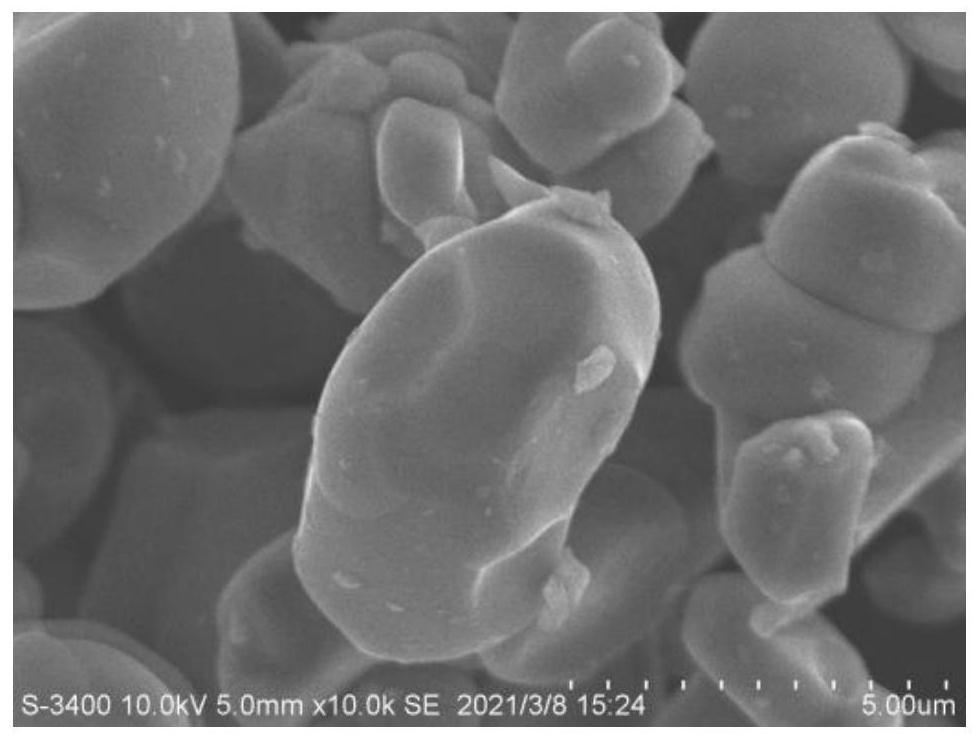

[0033] Precursor Ni of cathode material 0.83 mn 0.1 co 0.05 al 0.02 (OH) 2 , lithium source (LiOH·H 2 O) Dry mixing according to the following ratio: among them, the cathode material quaternary precursor and the lithium source (LiOH·H 2 The Li element in O) is mixed at a molar ratio of 1:1.03, using high-speed mixing equipment, mixing uniformly at a rotating speed of the equipment, mixing time: 20 minutes, rotating speed: 2000rpm, and mixing temperature 25±5°C. The mixed material was sintered at 850° C. for 10 h, and the calcination process was carried out in an oxygen atmosphere (97% concentration), cooled, pulverized and sieved to obtain the first product single crystal quaternary positive electrode material, and the first product was mixed with nano-LiMn 0.8 Fe 0.2 PO 4 According to the mass ratio of 1:5%, high-speed mixing equipment is used for mixing, and the equipment rotates to mix evenly. The mixing time is 10 minutes and the rotation speed is 1500rpm. After mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com