Silicon-based composite material as well as preparation method and application thereof

A silicon-based composite material and composite material technology, which is applied in silicon compounds, chemical instruments and methods, silicon oxide, etc., can solve the problems of ineffective buffer volume expansion, poor battery cycle performance, and poor coating surface compactness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

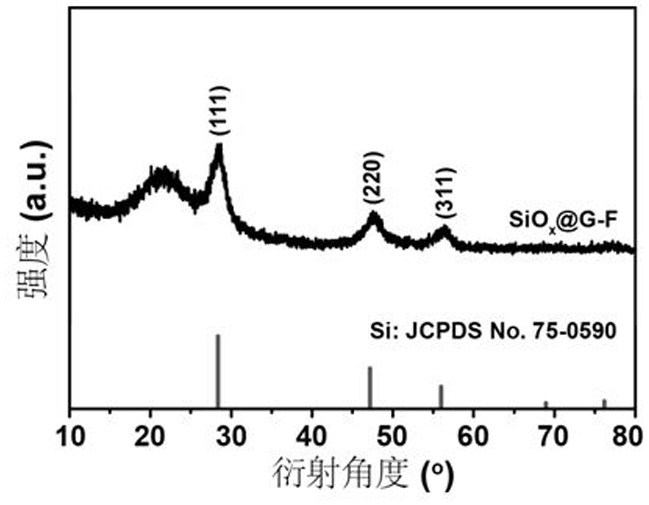

[0035] (1) Put the silicon element and silicon dioxide into the reactor at a mass ratio of 1:2, keep the temperature at 800 °C for 20 h at a vacuum of 0.1 Pa, and obtain silicon oxide after condensation and deposition.

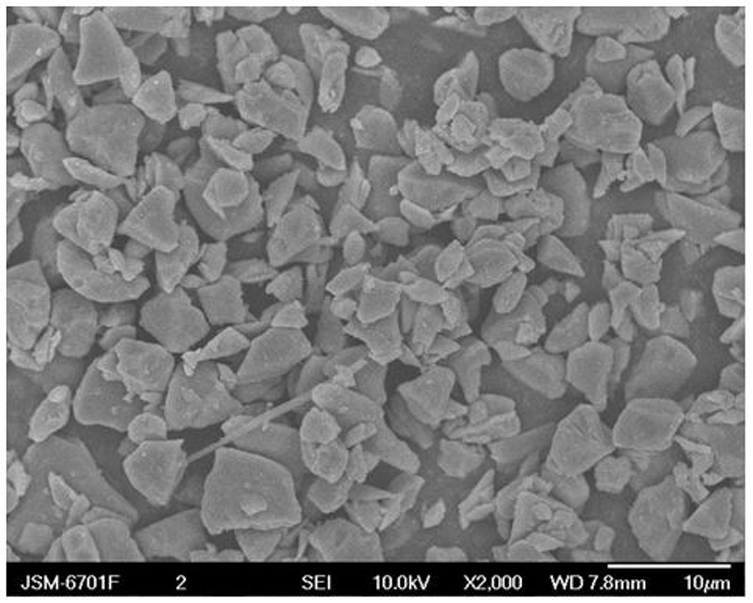

[0036] (2) Break the above-mentioned silicon oxide into particles with a particle size of 1-10 μm, and then add the particles into the reactor, place them in an inert atmosphere, and heat at 10 °C·min -1 After heating to 950 ℃, hydrogen and methane gas (volume flow ratio 1:3) are introduced to carry out carbon coating on the surface, and the coating is kept for 2 hours. After cooling to room temperature, silicon oxide coated with vertical graphene is obtained. Complex.

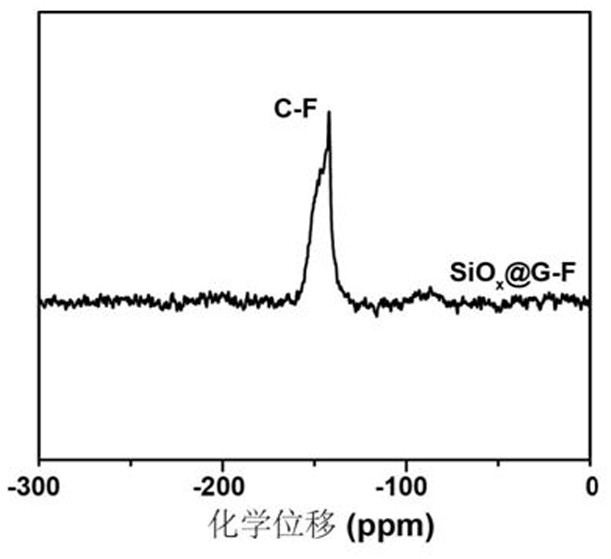

[0037] (3) Place the above-mentioned carbon-coated silicon-oxygen compound downstream of a dual-temperature zone heating furnace, and place polyvinylidene fluoride upstream, wherein the mass ratio of silicon-oxygen compound to polyvinylidene fluoride is 1:10; in an inert Atmosphere, upstream ...

Embodiment 2

[0045] The silicon-based composite material of the present invention was prepared according to the same method as in Example 1, except that the hydrogen gas in the step (2) was removed by treatment. Other steps are the same as the silicon-based composite negative electrode material obtained in Example 1.

Embodiment 3

[0047] The silicon-based composite material of the present invention was prepared in the same manner as in Example 1, except that the methane gas in the step (2) was replaced with acetylene. Other steps are the same as the silicon-based composite material obtained in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com