A kind of silicon matrix composite material and its preparation method and application

A technology of silicon-based composite materials and composite materials, applied in the direction of silicon compounds, chemical instruments and methods, silicon oxide, etc., can solve the problems of battery performance attenuation, destruction of silicon oxide silicon oxide structure, battery cycle performance deterioration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

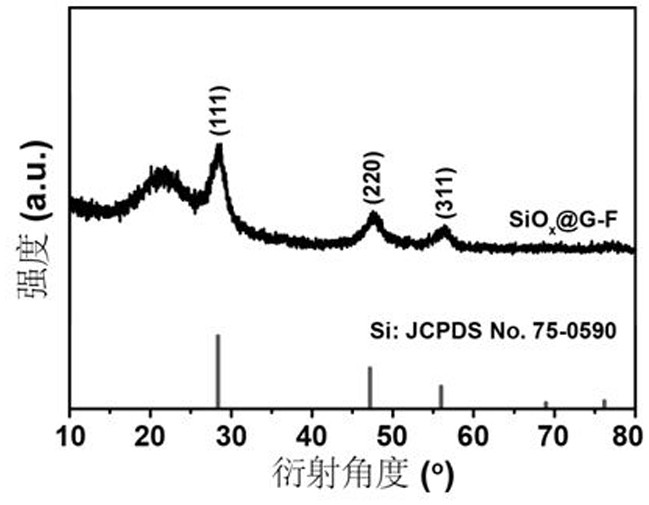

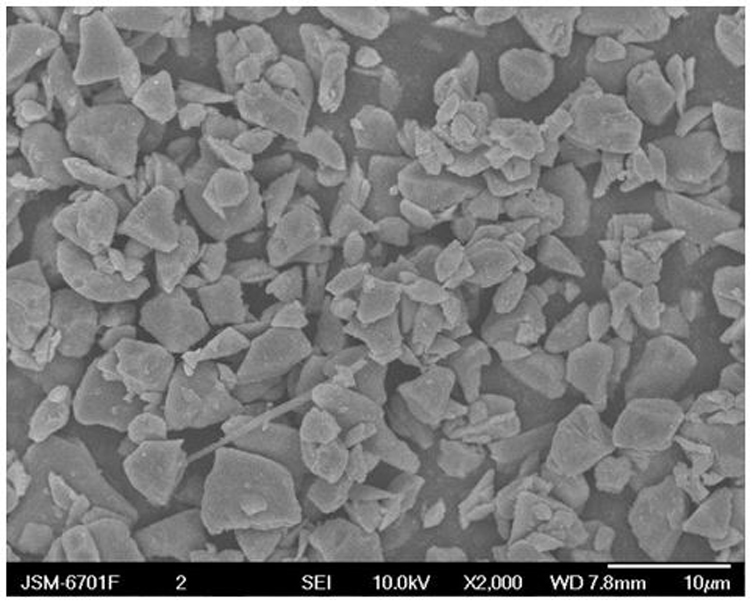

[0035] (1) Elemental silicon and silicon dioxide were added to the reactor at a mass ratio of 1:2, and kept for 20 h under the conditions of a vacuum degree of 0.1 Pa and a heating temperature of 800 °C, and silicon oxide was obtained after condensation deposition.

[0036] (2) The above silicon oxide is crushed to particles with a particle size of 1-10 μm, and then the particles are added to the reactor, placed in an inert atmosphere, and heated at 10 °C·min -1 After heating to 950 °C at a high heating rate at a high temperature, hydrogen and methane gas (volume flow ratio 1:3) were introduced for carbon coating on the surface, and the coating was kept for 2 h. After cooling to room temperature, a vertical graphene coating layer of silicon oxide was obtained. Complex.

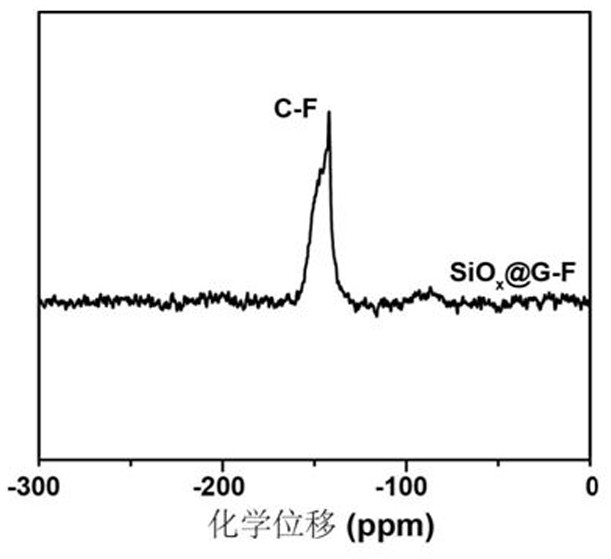

[0037] (3) The above carbon-coated silicon-oxygen composite is placed downstream of the dual-temperature zone heating furnace, and polyvinylidene fluoride is placed upstream, wherein the mass ratio of silicon-...

Embodiment 2

[0045] The silicon-based composite material of the present invention was prepared according to the same method as in Example 1, except that the hydrogen treatment in the step (2) was removed. Other steps are the same as the silicon-based composite negative electrode material obtained in Example 1.

Embodiment 3

[0047] The silicon-based composite material of the present invention was prepared according to the same method as in Example 1, except that the methane gas in the step (2) was replaced with acetylene. Other steps are the same as those of the silicon-based composite material obtained in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com