Preparation method of high-purity garlic polysaccharide

A garlic polysaccharide, high-purity technology, which is applied in the directions of medical preparations, pharmaceutical formulations, and digestive systems containing active ingredients, can solve the problems that the product purity is not high, it is difficult to realize industrialization, and it is not suitable for industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

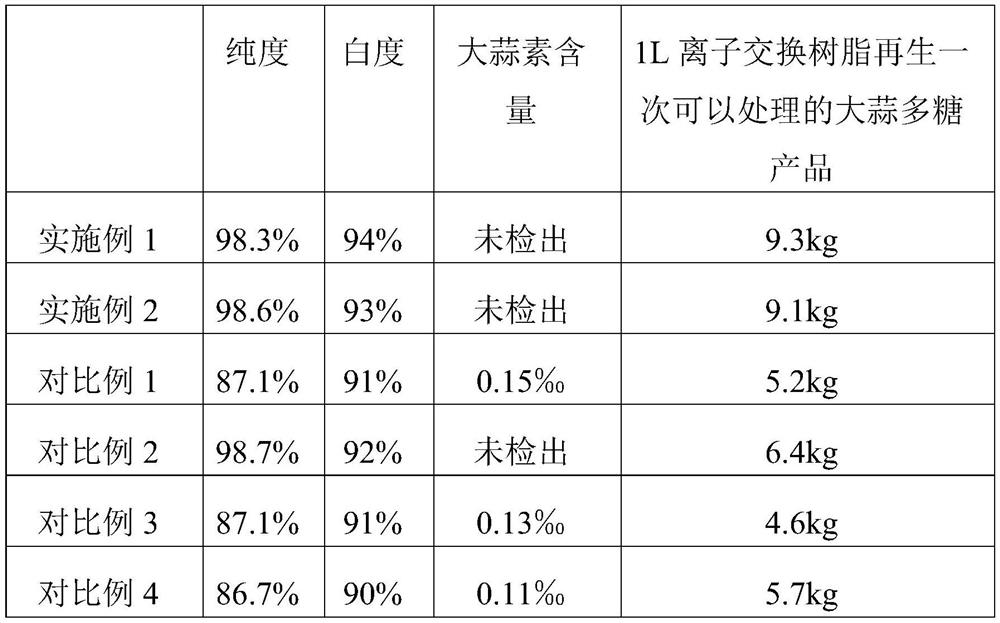

Embodiment 1

[0031] Take 500g of garlic slice water produced by processing dehydrated garlic slices, in which the garlic polysaccharide content is 6.4%, heat up to 30°C, add milk of lime to adjust the pH value to 9.0, keep warm for 10min, then heat up to 70°C, add lime with 1% of the weight of the feed liquid milk, keep warm for 20min; 2 Adjust the pH value to 9.0, heat up to 80°C after filtration, and pass CO 2 Adjust the pH value to 7.0, and filter again to obtain the clear liquid. Add 1% activated carbon to the clear liquid, raise the temperature to 30°C and stir for 30 minutes, filter and apply cation exchange resin LX-001 and anion exchange resin D296, then concentrate the column liquid and spray dry to obtain garlic polysaccharide. The garlic polysaccharide has a purity of 98.3%, a whiteness of 94%, no allicin detected, and no peculiar smell or taste of garlic. 1L ion exchange resin regeneration can process 9.3kg garlic polysaccharide product once.

Embodiment 2

[0033] After the garlic is crushed, extract it with water, take 500g of the extract, in which the garlic polysaccharide content is 7.5%, raise the temperature to 40°C, add lime milk to adjust the pH value to 10.0, heat it up to 80°C after holding for 30 minutes, add lime milk with 2% weight of the feed liquid , keep warm for 30min; pass CO 2 Adjust the pH value to 10.0, heat up to 90°C after filtration, and pass CO 2 Adjust the pH value to 7.5, and filter again to obtain the clear liquid. Add 1% activated carbon to the clear liquid, raise the temperature to 30°C and stir for 30 minutes, filter and apply cation exchange resin LX-001 and anion exchange resin D296, then concentrate the column liquid and spray dry to obtain garlic polysaccharide. The garlic polysaccharide has a purity of 98.6%, a whiteness of 93%, no allicin detected, and no peculiar smell or taste of garlic. 1L ion exchange resin regeneration can process 9.1kg garlic polysaccharide product once.

Embodiment 3

[0035] After the garlic is crushed, extract it with water, take 500g of the extract, in which the garlic polysaccharide content is 7.3%, raise the temperature to 35°C, add milk of lime to adjust the pH value to 9.5, heat it up to 85°C after holding for 30 minutes, add milk of lime with a weight of 2% of the feed liquid , keep warm for 30min; pass CO 2 Adjust the pH value to 10.0, heat up to 90°C after filtration, and pass CO 2 Adjust the pH value to 7.5, and filter again to obtain the clear liquid. Add 1% activated carbon to the clear liquid, raise the temperature to 30°C and stir for 30 minutes, filter the upper cation exchange resin LX-001 and anion exchange resin D296, and lower the column liquid for continuous chromatographic separation, using calcium-type strong cation resin as filler, optional Garlic polysaccharides with a degree of polymerization > 10 and garlic oligosaccharides with a degree of polymerization ≤ 10 are collected separately, concentrated, and spray-drie...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap