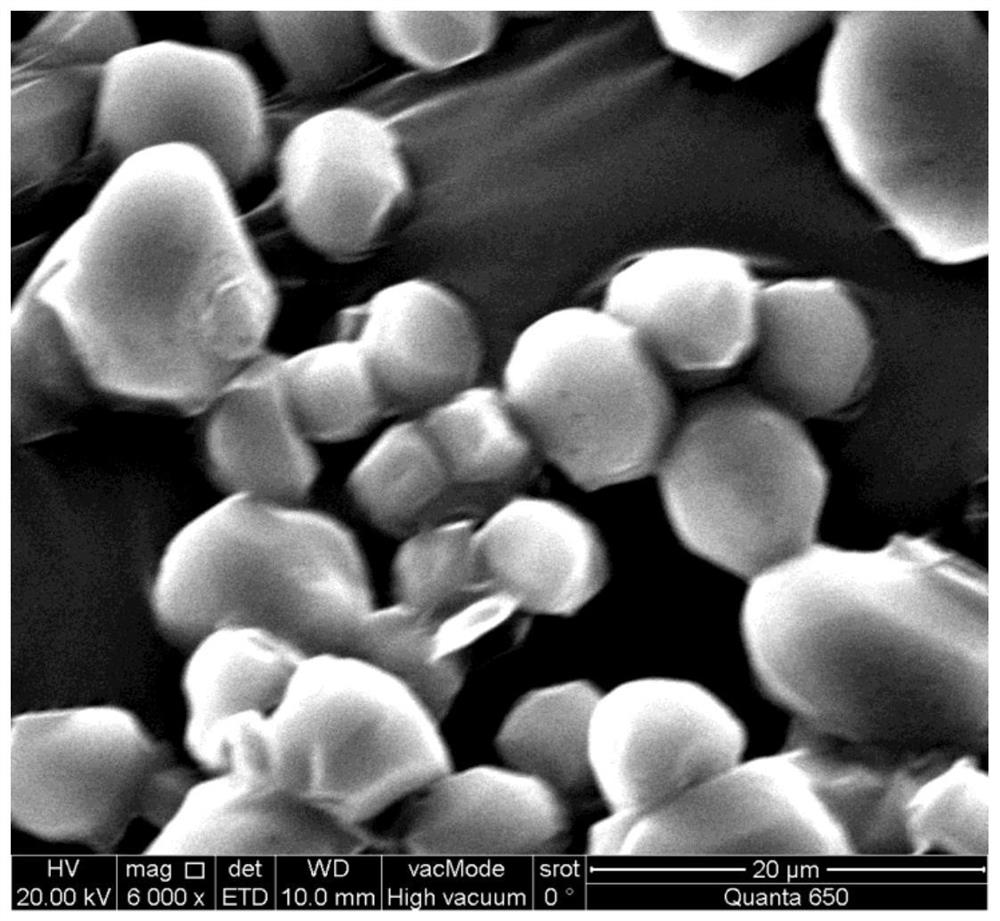

A kind of spherical adn particle, preparation method and application thereof

A particle and spherical technology, applied in chemical instruments and methods, offensive equipment, chemical/physical/physical-chemical reactors, etc., can solve the problems of difficult to prepare spherical ADN, high process risk, difficult implementation, etc., to reduce the temperature , high quality and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

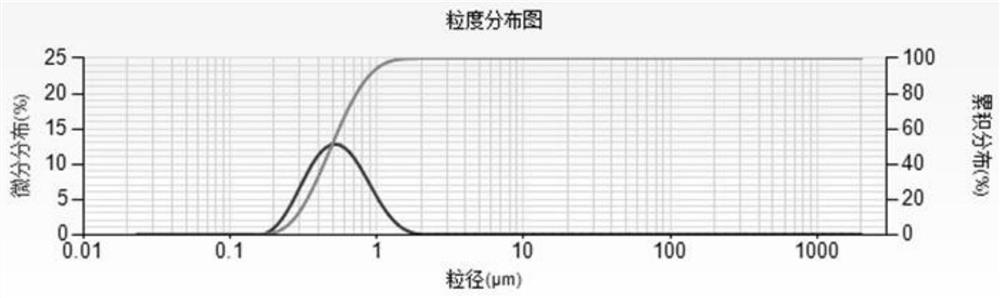

Embodiment 1

[0052] Weigh 5 g of ADN and dissolve in 15 g of acetone, and stir at 25° C. to completely dissolve the ADN to form an ADN solution. Take 100mL of simethicone in a beaker as anti-solvent A, and take 200mL of simethicone in a three-necked flask as anti-solvent B. Take a coaxial microchannel reactor with an inner channel inner diameter of 0.1 mm and an outer channel inner diameter of 0.5 mm, respectively use a peristaltic pump to inject the ADN solution into the inner channel of the microreactor at a drop rate of 0.05 mL / min, and simultaneously inject anti-solvent A with Dropping speed 0.5mL / min into the outer channel of the microreactor to form micro-droplets, drop the micro-droplets into the anti-solvent B, keep the reaction solution ultrasonically stirred, wherein the ultrasonic power is 800W, the stirring speed is 500rpm, after the dropwise addition, Turn off the ultrasound, continue to react for 2 hours, filter with suction, wash with dichloromethane three times, and dry the...

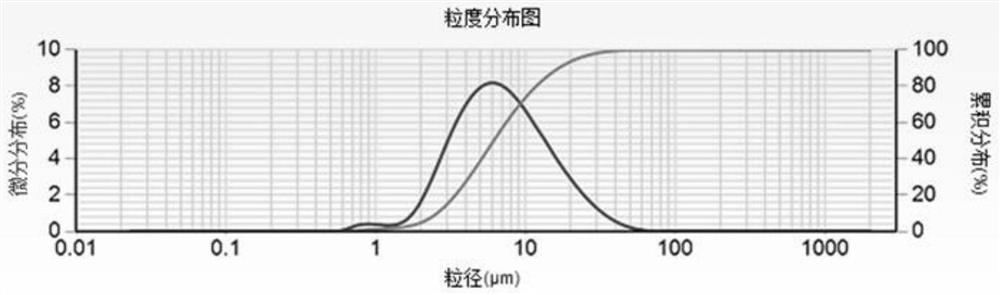

Embodiment 2

[0054] Weigh 4g of ADN and dissolve in 15g of acetonitrile, and stir to completely dissolve ADN to form an ADN solution. Take 100mL liquid paraffin in a beaker as anti-solvent A. Take 200mL liquid paraffin in a three-necked flask as anti-solvent B. Take a coaxial microchannel with an inner channel inner diameter of 0.8 mm and an outer channel inner diameter of 2 mm, respectively use a peristaltic pump to inject the ADN solution into the inner channel of the microreactor at a drop rate of 0.3 mL / min, and simultaneously inject anti-solvent A at a rate of 1.5 mL / min. Inject the micro-droplets into the outer channel of the microreactor at a drop speed of min to form micro-droplets, drop the micro-droplets into the anti-solvent B, and keep the reaction solution ultrasonically stirred, wherein the ultrasonic power is 1000W, and the stirring speed is 500rpm. After the dropwise addition, the ultrasound was turned off, and the reaction was continued for 2 hours, filtered with suction,...

Embodiment 3

[0056] Weigh 5g of ADN and dissolve in 20g of methyl ethyl ketone, and stir to completely dissolve ADN to form an ADN solution. Take 100mL white oil in a beaker as anti-solvent A. Take 200mL white oil in a three-necked flask as anti-solvent B. Take a coaxial microchannel reactor in which the inner diameter of the inner channel is 0.2 mm and the inner diameter of the outer channel is 1 mm. Use a peristaltic pump to inject the ADN solution into the inner channel of the microreactor at a drip rate of 0.2mL / min, inject the anti-solvent A0.8mL / min into the outer channel of the microreactor to form micro-droplets, and drop the micro-droplets into In the anti-solvent B, keep the reaction solution under ultrasonic stirring, wherein the ultrasonic power is 800W, and the stirring speed is 500rpm. After the dropwise addition, the ultrasound was turned off, and the reaction was continued for 2 hours, filtered with suction, washed with dichloromethane three times, and the solid was vacuu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com