Photosensitive phytic acid doped polyaniline-based ultraviolet curing anticorrosive coating and preparation method thereof

A polyaniline-based, anti-corrosion coating technology, applied in the direction of anti-corrosion coatings, polyester coatings, epoxy resin coatings, etc., can solve the problems of protonic acid without additional functional properties, poor resin compatibility, etc., and achieve cross-linking density and Adhesion improvement and effect of increasing crosslink density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

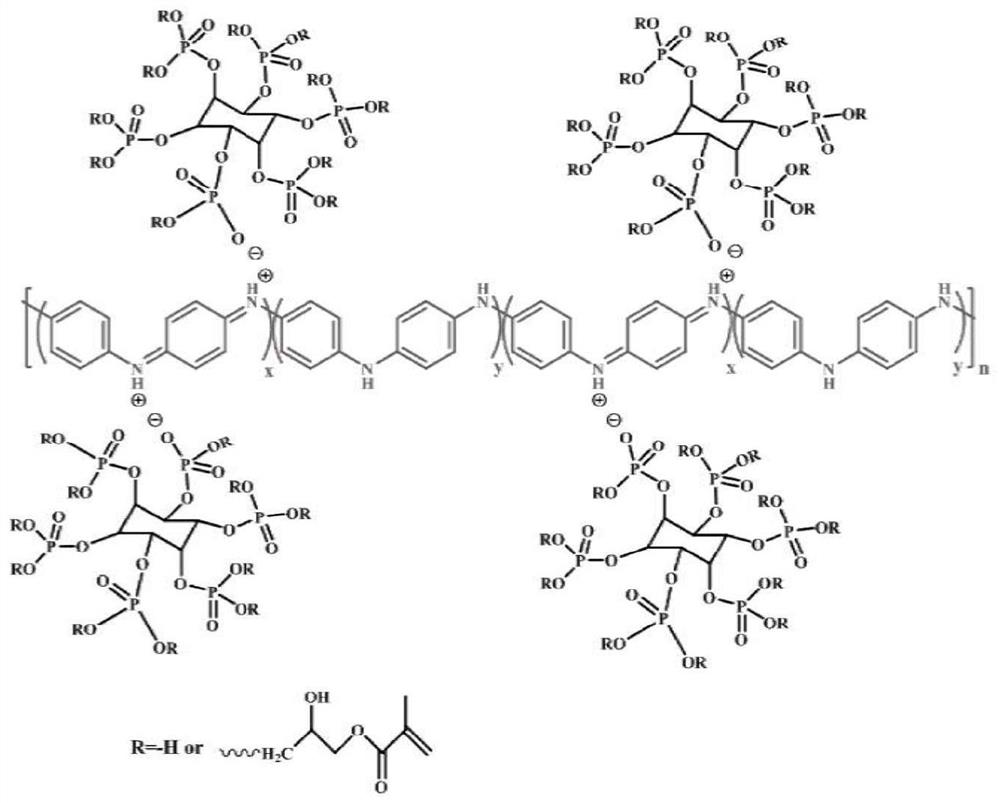

[0068] (1) Preparation of photosensitive phytic acid (PAGA-3): mix 0.025mol phytic acid with 40mL deionized water, then add 0.075mol GMA, add 0.1wt% terephthalic acid of phytic acid and glycidyl methacrylate Phenol as a polymerization inhibitor, phytic acid and glycidyl methacrylate in 0.5 wt% tetrabutylammonium bromide, after ultrasonic-assisted dispersion. The mechanical stirring speed was controlled at 150 rpm, and the reactant solution was reacted in an oil bath at 80°C for 0.5h to obtain a brown-yellow product, which was photosensitive phytic acid——PAGA-3.

[0069] (2) Preparation of photosensitive polyaniline: photosensitive phytic acid PAGA-3 is dispersed in deionized water to prepare a copolymer solution with a concentration of 0.2 g / mL, and photosensitive phytic acid and polyaniline (polyaniline particle size is 10 μm) are mixed in the solution. Add polyaniline at a mass ratio of 10:1, control the reaction time to 6.0 h under stirring, filter and wash to obtain photos...

Embodiment 2

[0073] (1) Preparation of photosensitive phytic acid (PAGA-5): mix 0.025mol phytic acid with 40mL deionized water, then add 0.125mol GMA, add phytic acid and 0.1wt% p-tert-butyl methacrylate of glycidyl methacrylate Hydroquinone as the polymerization inhibitor, phytic acid and glycidyl methacrylate in 1.0 wt% tetrabutylammonium bromide, after ultrasonic-assisted dispersion. The mechanical stirring speed was controlled at 150rpm, and the reactant solution was reacted in an oil bath at 90°C for 1.0h to obtain a brown-yellow product, which was photosensitive phytic acid——PAGA-5.

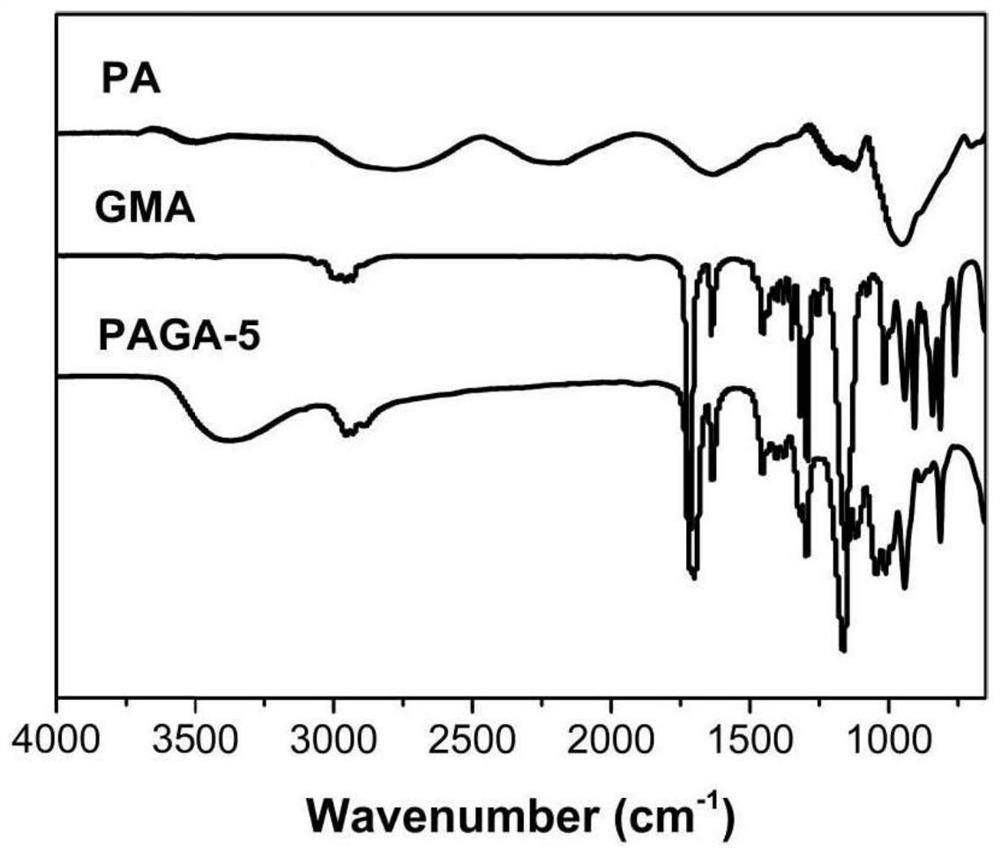

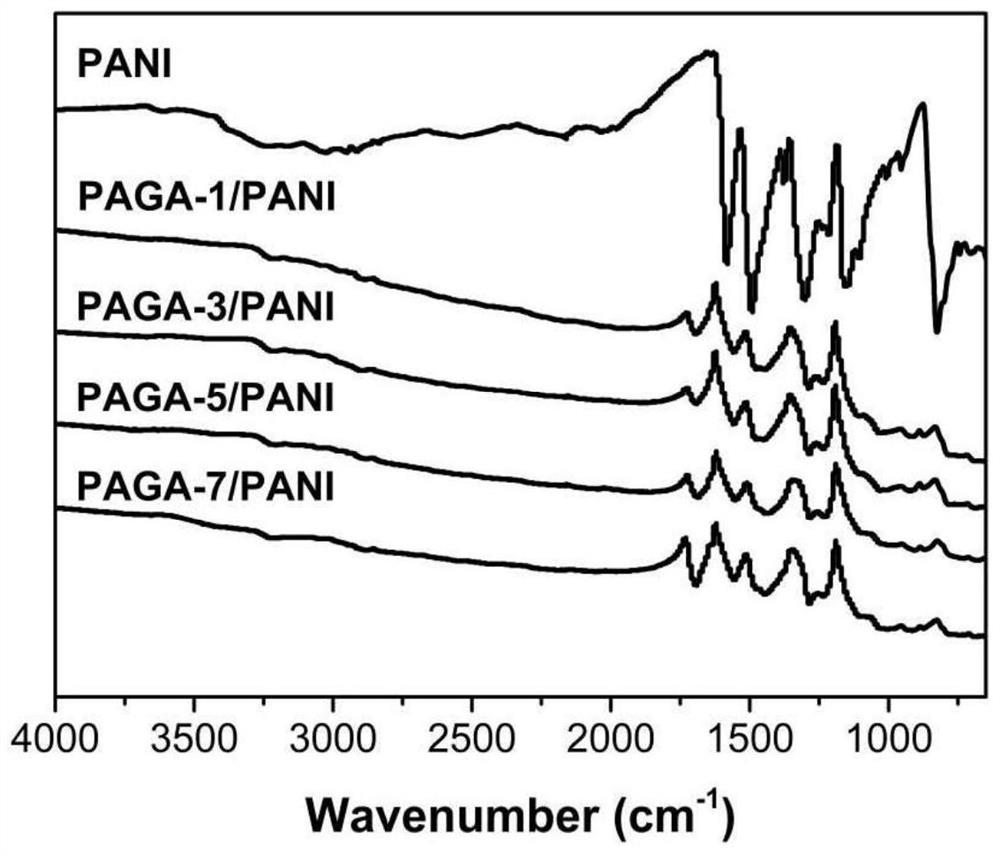

[0074] figure 1 Be the infrared spectrogram of PA, GMA and PAGA-5, there is the characteristic absorption peak (1164cm -1 ). For GMA, in addition to the characteristic absorption peak (910cm -1 ), you can also see the characteristic absorption peak of the unsaturated carbon-carbon double bond (1635cm -1 and 810cm -1 ) and the characteristic absorption peak attributed to the carbonyl group (1720cm ...

Embodiment 3

[0078] (1) Preparation of photosensitive phytic acid (PAGA-7): mix 0.025mol phytic acid with 40mL deionized water, then add 0.175mol GMA, add phytic acid and 0.5wt% of glycidyl methacrylate p-tert Butylcatechol as a polymerization inhibitor, phytic acid and glycidyl methacrylate with 1.0 wt% triphenylphosphine, after ultrasonic-assisted dispersion. The mechanical stirring speed was controlled at 150 rpm, and the reactant solution was reacted in an oil bath at 85°C for 2.0 hours to obtain a brownish-yellow product, which was photosensitive phytic acid——PAGA-7.

[0079] (2) Preparation of photosensitive polyaniline: photosensitive phytic acid PAGA-7 is dispersed in deionized water to prepare a copolymer solution with a concentration of 1.0 g / mL, and polyaniline is added to the solution at a mass ratio of photosensitive phytic acid to polyaniline of 25:1. Aniline, control the reaction time to 10h under stirring, filter and wash to obtain photosensitive polyaniline.

[0080] (3) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com