Nanoparticles prepared by applying microfluidic technology, preparation method and device and application

A microfluidic technology and nanoparticle technology are applied in the fields of preparing nanoparticles by applying microfluidic technology, preparation, devices and uses, which can solve the problems of unstable system, easy carrier material, low dispersibility, etc., and achieve good dispersibility. stability, good biocompatibility, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

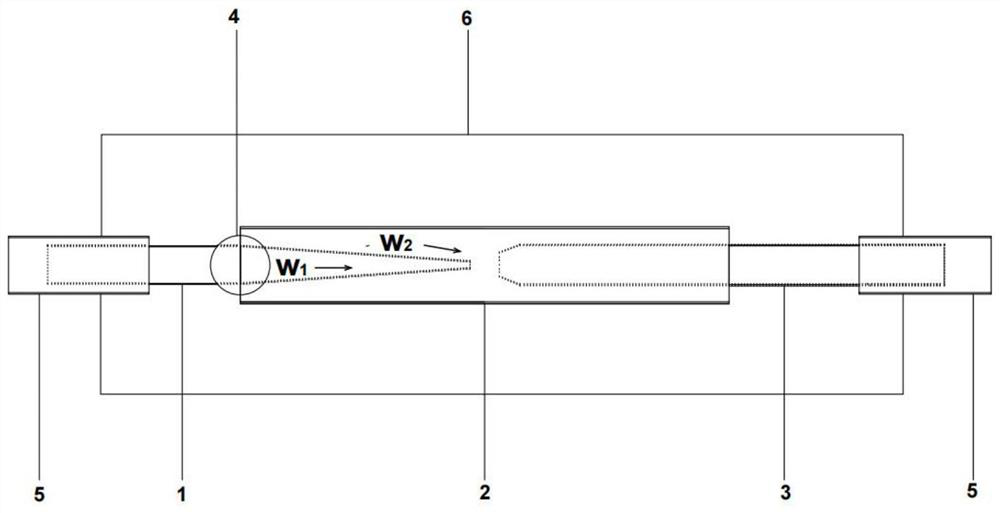

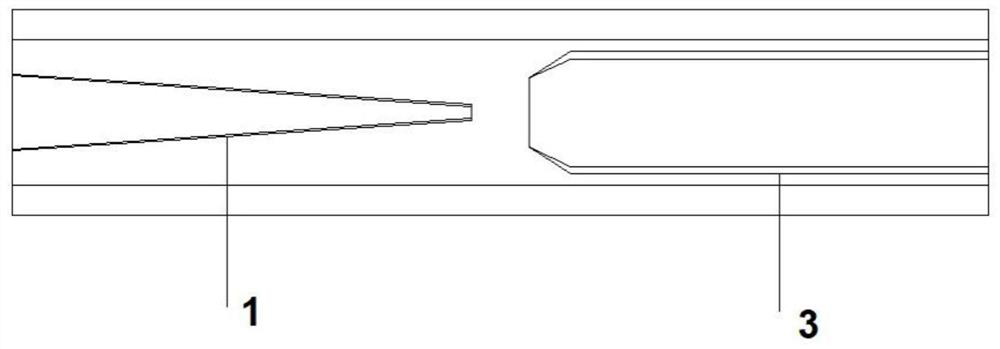

[0049] Example 1: Construction of a glass microfluidic device

[0050] The glass microfluidic device is a single-emulsion device prepared by a self-made one-step method, including an inner phase capillary 1, an outer phase capillary 3, a square tube 2, a sampling needle 4, two iron tubes 5 and a glass slide 6. Use a needle pulling device to burn a long capillary into two to three sections, and then use a needle grinder to burn and pull the needle pulling device to prepare the two capillary tips required for the experiment to be polished to 40-60μm and 200-400μm respectively. , as inner phase capillary 1 and outer phase capillary 3. Specifically, place the two polished capillaries on the observation platform of an inverted microscope, and observe whether the thickness of the tips of the two capillaries meets the experimental requirements through the microscope eyepiece and the JIFEI microscope-specific measurement software on the computer side connected to the microscope. Firs...

Embodiment 2

[0051] Embodiment 2: the preparation of nanoparticle

[0052] (1) Preparation of two-phase solution

[0053] Weigh a part of CAPE (0.01-0.1% w / v) and shellac (0.5-4.0% w / v) and dissolve in 1ml of ethanol, place on a magnetic stirrer and stir until completely dissolved (if the stirring is not completely dissolved, use a vortex Mixer to aid in dissolving) to prepare the inner aqueous phase solution, dissolve gum arabic (0-2.5% w / v) in deionized water, place the solution on a vortex mixer to quickly dissolve the gum arabic, and obtain the outer aqueous phase Solution, wherein the ratio of ethanol to water is (1:5, 1:10, 1:15 and 1:20).

[0054] (2) Preparation of nanoparticles

[0055] Inhale the inner aqueous phase solution into a 1ml disposable sterile medical syringe, and at the same time use a 5ml disposable sterile medical syringe to absorb the outer aqueous phase solution, fix the inner phase and outer phase syringes on two syringe pumps respectively, The tetrafluoroethy...

Embodiment 3

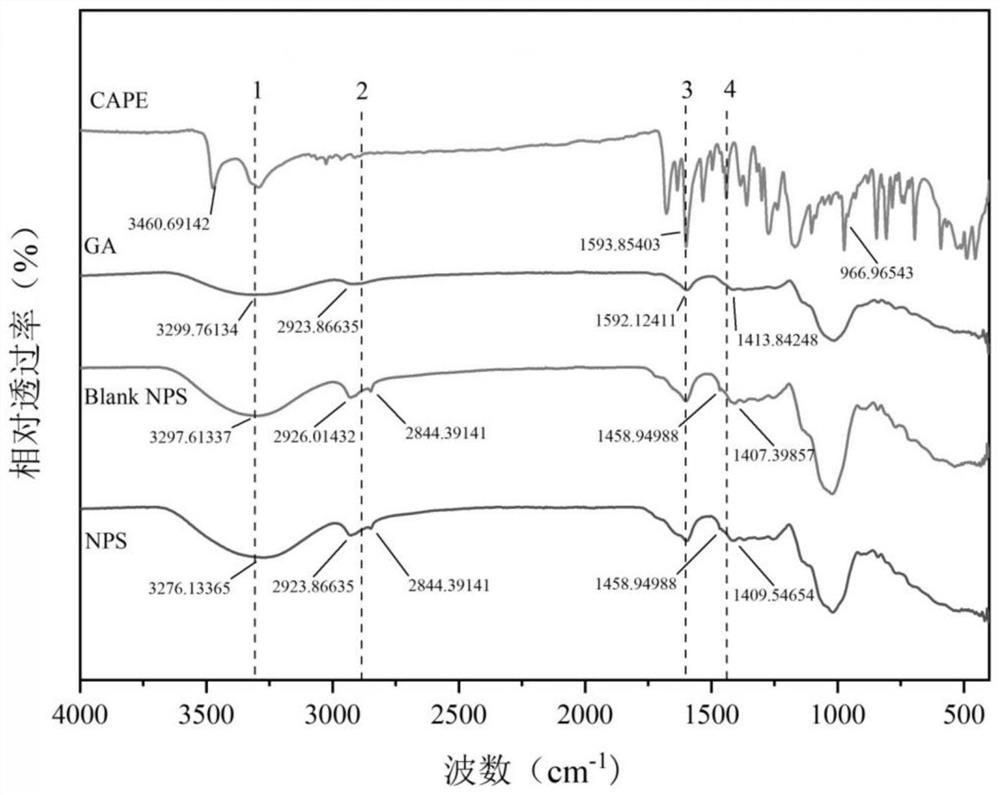

[0059] Example 3: Characterization of Nanoparticles

[0060] (1) Characterization of the particle size of the nanoparticles: the effect of the used material parameters on the particle size and potential of the nanoparticles was investigated.

[0061] Under the condition that the above-mentioned conditions for the preparation of nanoparticles remain unchanged, the effects of the concentration of gum arabic, the concentration of shellac, and the ratio of solvent to antisolvent on the particle size and potential of nanoparticles were investigated respectively, and the particle size was measured by Anton Paar laser particle size analyzer (Litesizer500). Particle Size Distribution and Zeta Potential.

[0062] Discussion of results: attached Figure 4 , 5 , 6, through different groups of single factor experiments, it was found that the particle size and potential measurement results of nanoparticles prepared with different concentration groups of gum arabic concentration showed th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com