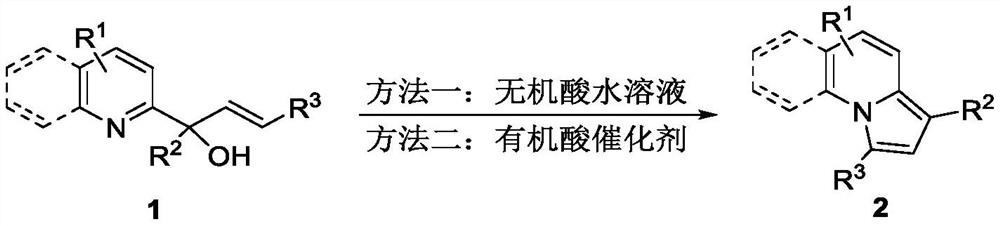

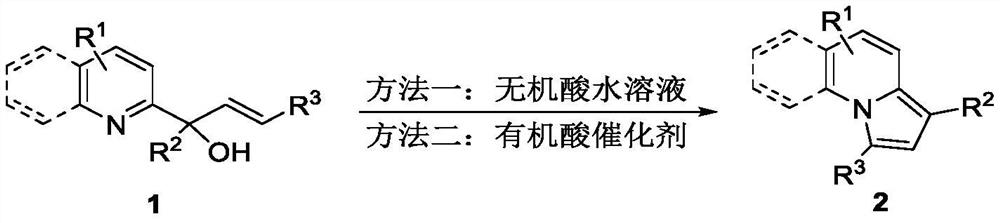

Simple synthesis method of 1-alkyl-3-aryl substituted indolizine compound

A synthesis method and compound technology, applied in organic chemistry and other directions, can solve the problems of complex synthesis method, time-consuming and labor-intensive substrate synthesis, etc., and achieve the effects of simple synthesis process, simple operation, and easy availability of raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

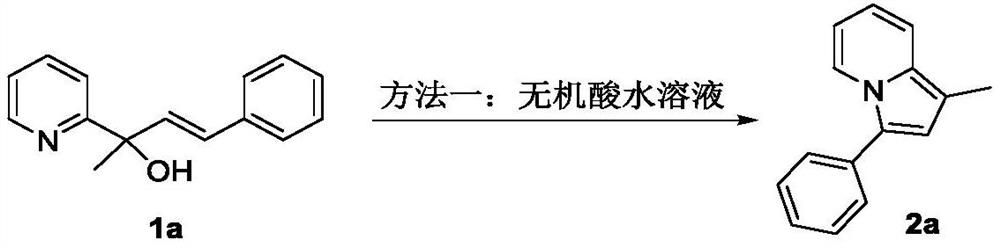

Embodiment 1

[0026]

[0027] Method 1: Into a 10mL reaction tube equipped with a reflux condensing device, add compound 1a and an aqueous inorganic acid solution, place in an oil bath to heat up and stir for reaction. After the reaction is completed, cool to room temperature, dilute with water, and then add potassium carbonate to neutralize the acidic aqueous solution until the reaction solution is alkaline and has a pH of 8-10. Ethyl acetate was extracted three times, the combined organic phases were dried, filtered and spin-dried, and separated on a silica gel column (petroleum ether) to obtain the green oily product 2a.

[0028] By changing reaction conditions such as inorganic acid concentration, solvent amount and reaction temperature of reaction, reaction result is as follows:

[0029] Synthesis of 2a under different conditions in table 1 a

[0030]

Embodiment 2

[0032]

[0033] Method 2: Add compound 1a, an organic acid catalyst, and an organic solvent into a 10mL reaction tube equipped with a reflux condensing device, mix thoroughly, and place in an oil bath to heat up and stir for reaction. After the reaction was completed, it was cooled to room temperature, spin-dried, and separated on a silica gel column (petroleum ether) to obtain the green oily product 2a.

[0034] By changing reaction conditions such as the organic acid catalyst of reaction and its consumption, organic solvent, solvent amount and reaction temperature, reaction result is as follows:

[0035] Synthesis of 2a under different conditions in table 2 a

[0036]

Embodiment 3

[0038]

[0039] Method 1: Add (E)-4-phenyl-2-pyridyl-3-enyl-2-ol (1a, 45.0mg, 0.2mmol) and 3.5M Aqueous hydrochloric acid solution (3 mL) was mixed thoroughly, and then stirred at 100° C. for 12 hours under an air atmosphere. After the reaction is completed, cool to room temperature, dilute with water, then add potassium carbonate to neutralize the acidic aqueous solution until the reaction solution is alkaline pH=8-10, extract three times with ethyl acetate, combine the organic phases to dry, filter with suction, spin dry, and pass through a silica gel column Isolation (petroleum ether) gave the product 2a (39.0 mg, 94%) as a green oil.

[0040] Method 2: Add (E)-4-phenyl-2-pyridyl-3-enyl-2-ol (1a, 45.0mg, 0.2mmol), p-toluene to a 10mL reaction tube equipped with a reflux condenser Sulfonic acid (3.8mg, 0.01mmol) and N,N-dimethylformamide (3mL) were thoroughly mixed and stirred at 100°C for 12 hours under air atmosphere. After the reaction was completed, it was cooled to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com