Low-birefringence polyimide film and preparation method thereof

A technology of polyimide film and low birefringence, which is applied in the field of optical materials, can solve the problems of light delay, increase the color shift of different viewing angles, reduce the black and white contrast of the display, and achieve the effect of low birefringence performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The present invention also proposes a preparation method of a low-birefringence polyimide film, specifically comprising:

[0037] (1) first in an organic solvent, alicyclic dianhydride, terephthaloyl dichloride and isophthaloyl dichloride are mixed and polycondensed with aromatic diamine to obtain a polyamic acid solution;

[0038] The above-mentioned solvent can be selected from N-methylpyrrolidone, N, N-dimethylacetamide, N, N-dimethylformamide, dimethyl sulfoxide, m-cresol, chloroform, tetrahydrofuran, γ-butyrolactone or at least one of 3-methyl-N,N-dimethylpropanamide.

[0039] (2) adding a dehydrating agent and a catalyst to the obtained polyamic acid solution for imidization reaction, and then dropping into a poor solvent for precipitation to obtain a polyimide;

[0040] The above-mentioned dehydrating agent can be selected as at least one of acetic anhydride, propionic anhydride, butyric anhydride or benzoic anhydride; the catalyst can be selected as pyridine, p...

Embodiment 1

[0046] A kind of low birefringence polyimide film, its preparation method comprises:

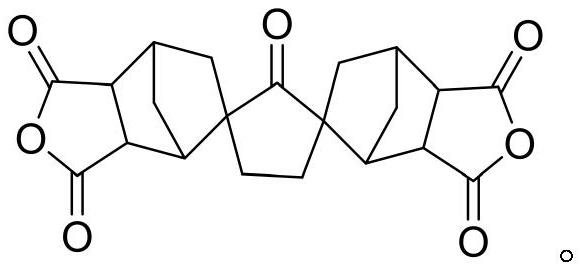

[0047] Under nitrogen protection, 2.2416g (7mmol) 2,2'-bis(trifluoromethyl)diaminobiphenyl (TFDB) and 1.0453g (3mmol) 9,9'-bis(4-aminophenyl)fluorene ( FDA) was added into 60mLN, N-dimethylacetamide and stirred to dissolve completely, then added 0.8885g (2mmol) 4,4'-hexafluoroisopropylphthalic anhydride (6FDA), 1.1523g (3mmol) Bornane-2-spironolactone-α-cyclopentanone-α'-spironolactone-2"-norbornane-5,5",6,6"-tetracarboxylic dianhydride (CpODA) and 1.0152g (5mmol) of Phthaloyl chloride (TPC), stirred and reacted at 30°C for 10h, then added 2.25g of isoquinoline and 2.65g of acetic anhydride, stirred at room temperature for 1h, continued stirring at 80°C for 1h, and added the resulting reaction solution dropwise to excess methanol Precipitated in the solution, filtered and rinsed with a large amount of methanol, then crushed the obtained precipitate, and dried in vacuum at 80°C for 5 hours t...

Embodiment 2

[0051] A kind of low birefringence polyimide film, its preparation method comprises:

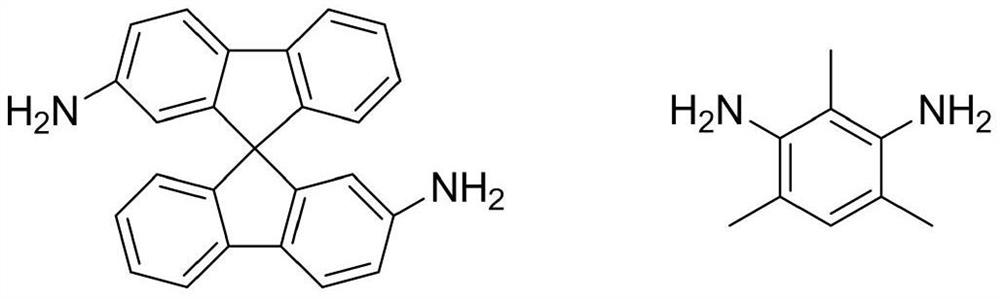

[0052] Under nitrogen protection, 2.2416g (7mmol) 2,2'-bis(trifluoromethyl)diaminobiphenyl (TFDB) and 0.4507g (3mmol) 2,4,6-trimethyl-1,3-benzene Add diamine (DAM) into 60mL N,N-dimethylacetamide and stir to dissolve completely, then add 0.8885g (2mmol) 4,4'-hexafluoroisopropylphthalic anhydride (6FDA), 1.1523g (3mmol) norbornane-2-spironolactone-α-cyclopentanone-α'-spirolactone-2"-norbornane-5,5",6,6"-tetracarboxylic dianhydride (CpODA) and 1.0152g (5mmol) terephthaloyl chloride (TPC), stirred and reacted at 30°C for 10h, then added 2.25g of isoquinoline and 2.65g of acetic anhydride, stirred at room temperature for 1h, continued to stir for 1h at 80°C, and the resulting reaction droplets Add to excess methanol to precipitate, filter and rinse with a large amount of methanol, then pulverize the obtained precipitate, and vacuum dry at 80°C for 5 hours to obtain polyimide powder;

[0053] A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com