Preparation method of biological piezoelectric coating on surface of titanium-based material

A titanium-based and coating technology, which is applied in the field of surface modification of biomedical materials, can solve the problems of poor biological activity, drug loading, and drug release performance that cannot meet the needs of clinical controllable long-term treatment, so as to promote osseointegration, The effect of reducing the risk of loosening and complications and shortening the bone repair process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

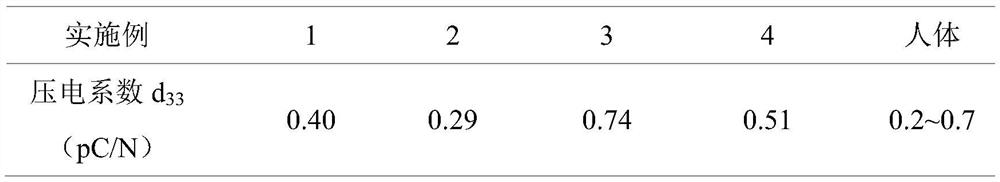

Embodiment 1

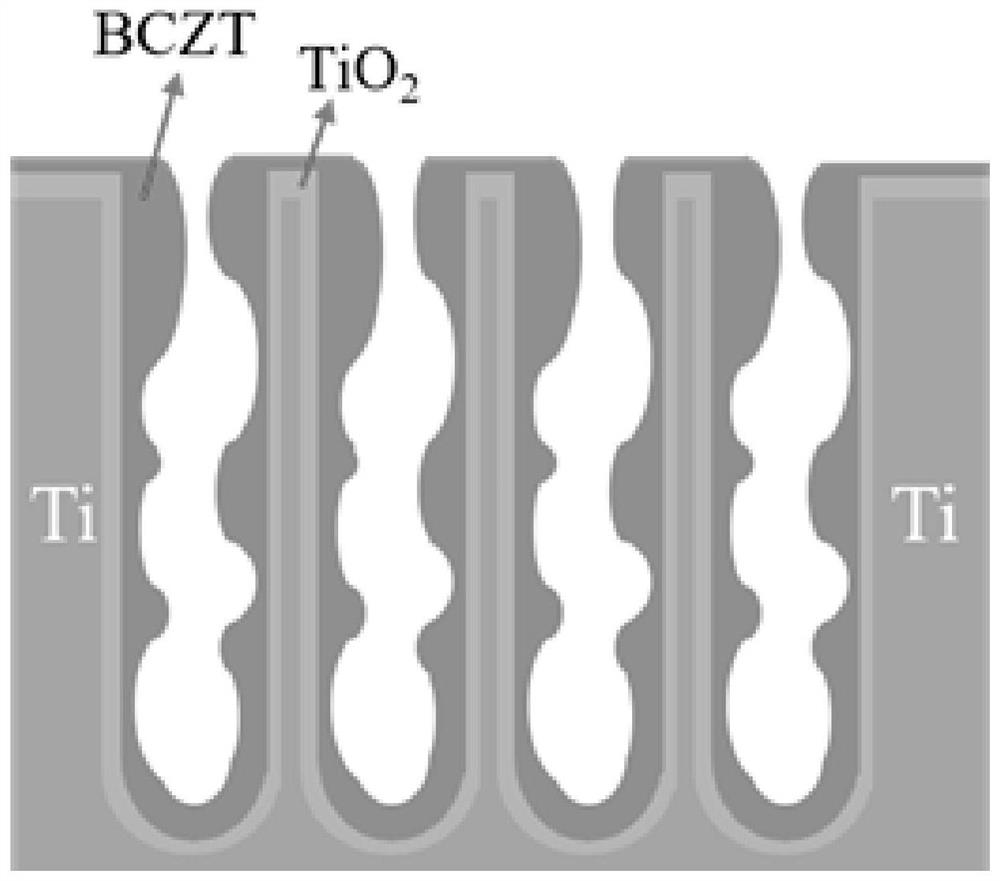

[0053] Preparation of Ba on the surface of pure titanium 0.85 Ca 0.15 Zr 0.10 Ti 0.90 o 3 Specific nanotube piezoelectric coating, specifically implemented according to the following steps:

[0054] Step 1, use SiC sandpaper to polish pure titanium until the surface is smooth, then immerse in the prepared acidic lotion for chemical polishing, pickle until no bubbles are generated, then ultrasonically clean with absolute ethanol and deionized water, and dry for backup use.

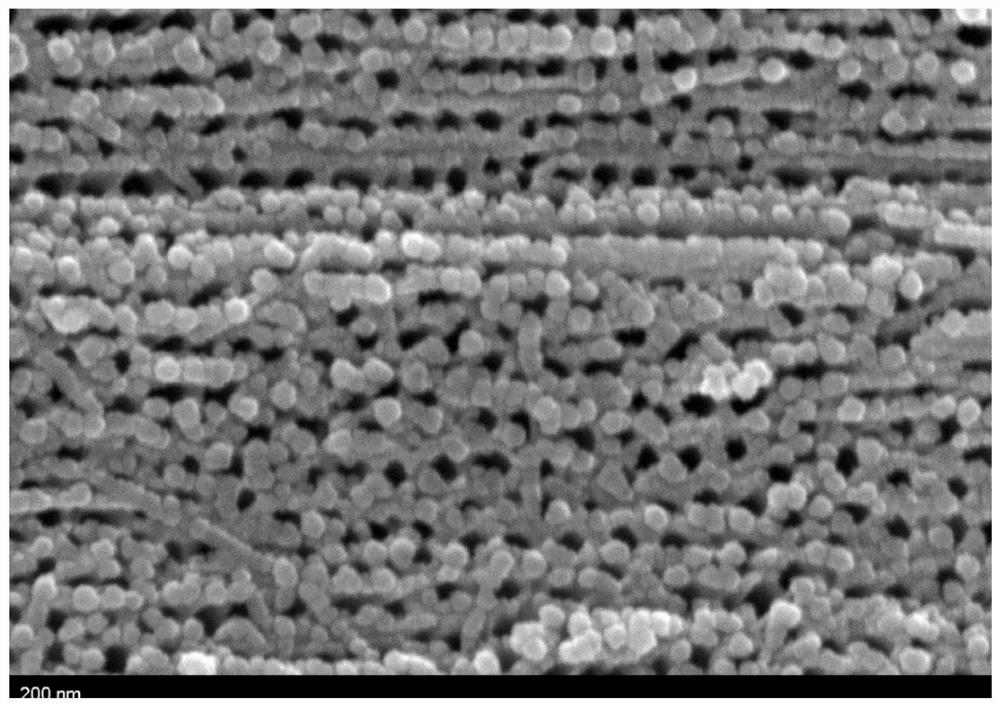

[0055] Step 2, add ammonium fluoride and deionized water to ethylene glycol at 0.5wt%, 2vol%, and stir evenly to obtain an electrolyte; use the platinum sheet as the cathode, and the pure titanium treated in step 1 as the anode, and fix the anode and the cathode. The distance between them is 5mm, the voltage of primary anodic oxidation is 60V, the time is 1h, the voltage of secondary anodic oxidation is 60V, and the time is 0.5h, so that the titanium sheet undergoes anodic oxidation reaction. Ultrason...

Embodiment 2

[0059] Preparation of Ba on the surface of titanium nails 0.85 Ca 0.15 Zr 0.10 Ti 0.90 o 3 Specific nanotube piezoelectric coating, specifically implemented according to the following steps:

[0060] Step 1, use SiC sandpaper to polish the titanium nails until the surface is smooth, then immerse in the prepared acidic lotion for chemical polishing, pickle until no bubbles are generated, then ultrasonically clean with absolute ethanol and deionized water, and dry for backup use.

[0061] Step 2, add ammonium fluoride and deionized water to ethylene glycol at 0.2wt%, 10vol%, and stir evenly to obtain an electrolyte; use the platinum sheet as the cathode, and the titanium nail treated in step 1 as the anode, and fix the anode and the cathode. The distance between them is 30mm, the voltage of the first anodization is 40V, the time is 4h, the voltage of the second anodization is 40V, the time is 1h, so that the anodization reaction occurs on the titanium nail, and the titanium...

Embodiment 3

[0065] Preparation of Ba on the surface of titanium alloy stent 0.85 Ca 0.15 Zr 0.10 Ti 0.90 o 3 Specific nanotube piezoelectric coating, specifically implemented according to the following steps:

[0066]Step 1, use SiC sandpaper to polish the titanium alloy bracket until the surface is smooth, then immerse in the prepared acidic lotion for chemical polishing, pickle until no bubbles are generated, then ultrasonically clean with absolute ethanol and deionized water, and dry Backup.

[0067] Step 2, add ammonium fluoride and deionized water at 0.6wt%, 5vol% to ethylene glycol and stir evenly to obtain an electrolyte; use the platinum sheet as the cathode, and the titanium alloy bracket treated in step 1 as the anode, and fix the anode and cathode The distance between them is 20mm, the voltage of primary anodic oxidation is 60V, the time is 1h, the voltage of secondary anodic oxidation is 60V, and the time is 0.5h, so that the anodic oxidation reaction of titanium alloy br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com