Preparation process of antibacterial and deodorant socks

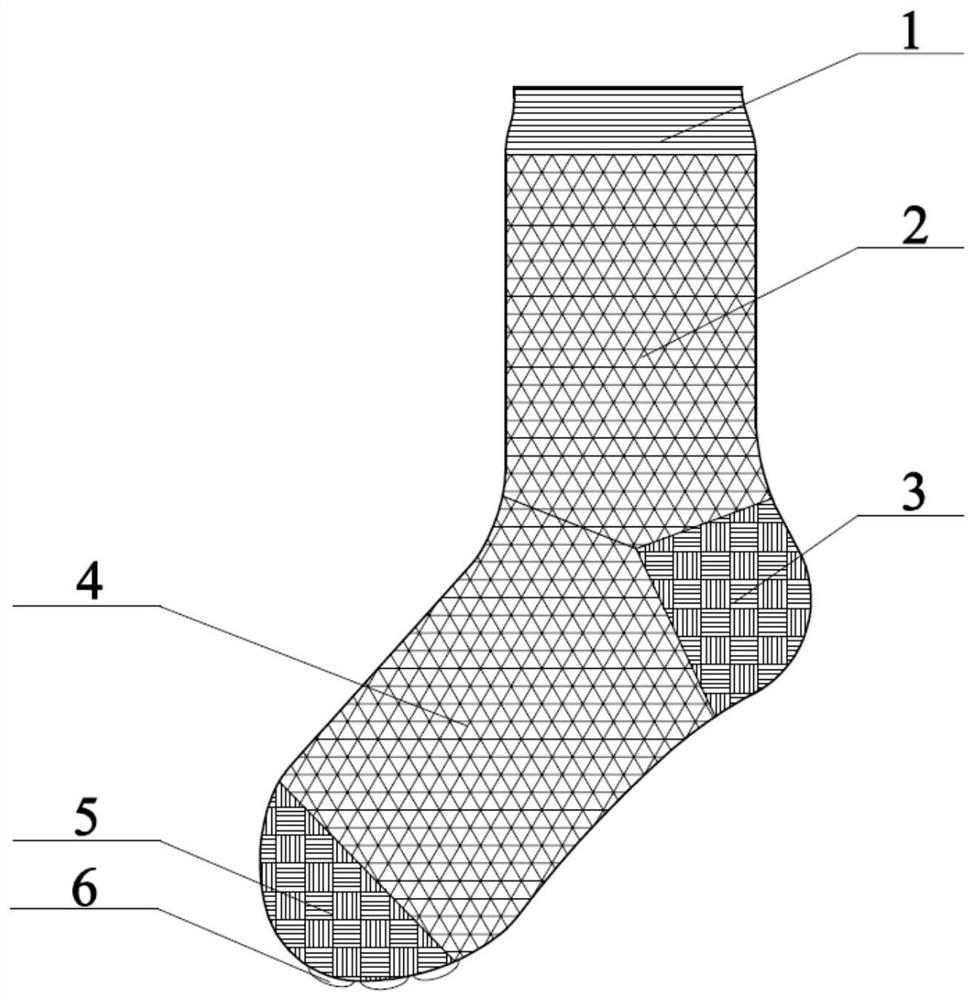

A preparation process, a technology for socks, applied in the manufacture of socks, pantyhose, rayon, etc., can solve the problems of easy yellowing of nano silver, easy generation of static electricity, poor dispersion of polyester chips, etc., to improve flammability and antistatic ability, enhanced friction, improved wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

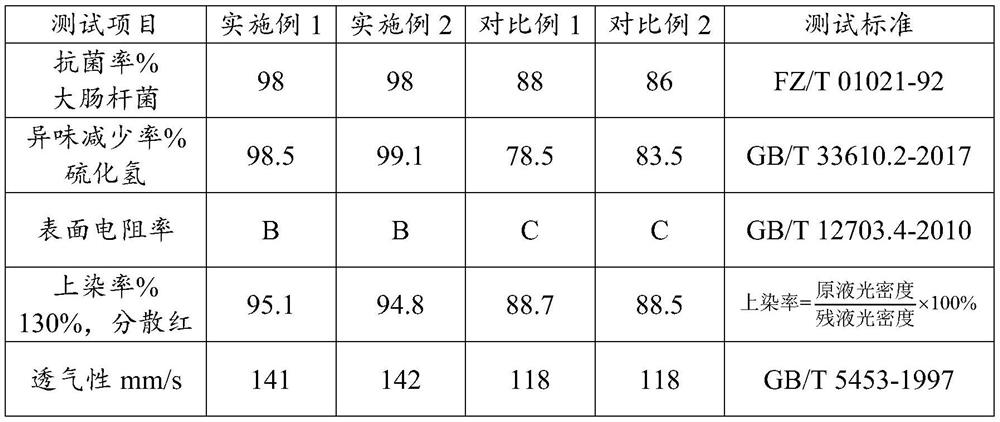

Examples

example 1

[0041] a) Weigh a certain amount of citric acid, zinc nitrate hexahydrate and silver nitrate and dissolve them in a deionized water-triethanolamine mixed solution with a volume ratio of 1:4, the zinc nitrate hexahydrate: citric acid: silver nitrate mass The ratio is 263:130:1. Stir continuously at room temperature, and add sodium hydroxide solution with a concentration of 2Kg / L to the mixed solution dropwise within 30 minutes. After stirring for 20 minutes, heat up to 160°C. Control the temperature at React at 160°C for 16 hours, and obtain Ag / ZnO powder after filtration;

[0042] b) Weigh a certain amount of Ag / ZnO powder, add ethanol and stir for 30 minutes, the mass ratio of ethanol:Ag / ZnO powder is 2:1, heat up to 80°C, add polyvinyl alcohol at 80°C, The mass ratio of the polyvinyl alcohol:Ag / ZnO powder is 2.4:1, the reaction is 2.5 in the state of stirring and condensing and reflux, standing for stratification, removing the lower layer of powder, drying and grinding to ob...

example 2

[0047] a) Weigh a certain amount of citric acid, zinc nitrate hexahydrate and silver nitrate and dissolve them in the deionized water-triethanolamine mixed solution with a volume ratio of 1:6. The ratio is 263:132:1.1. Stir continuously at room temperature, and slowly add sodium hydroxide solution with a concentration of 2Kg / L to the mixed solution within 30 minutes, stir fully for 25 minutes, and react at constant temperature for 16 hours at 160°C. After filtration Obtain Ag / ZnO powder;

[0048] b) Weigh a certain amount of Ag / ZnO powder, add ethanol and stir for 30min, the mass ratio of ethanol:Ag / ZnO powder is 2:1, add polyvinyl alcohol at 80°C, the polyvinyl alcohol: The mass ratio of Ag / ZnO powder is 3.1:1, react for 3.0h in the state of stirring and condensing and refluxing, let stand for stratification, remove the lower layer of powder, dry and grind to obtain PVA-coated Ag / ZnO powder;

[0049] c) Weigh quantitative PVA-coated Ag / ZnO powder, chitosan, and graphene oxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com