Method for realizing comprehensive utilization of iron, vanadium and titanium through low-temperature reduction roasting of vanadium titano-magnetite

A vanadium-titanium magnetite and low-temperature technology, which is applied in the field of low-temperature reduction roasting of vanadium, iron, vanadium-titanium magnetite, and comprehensive utilization of titanium, can solve the problems of strong corrosion, easy volatilization, and only a few times of use, and achieve Corrosion and volatilization are weakened, reducing dosage is small, and the effect of reducing carbon emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

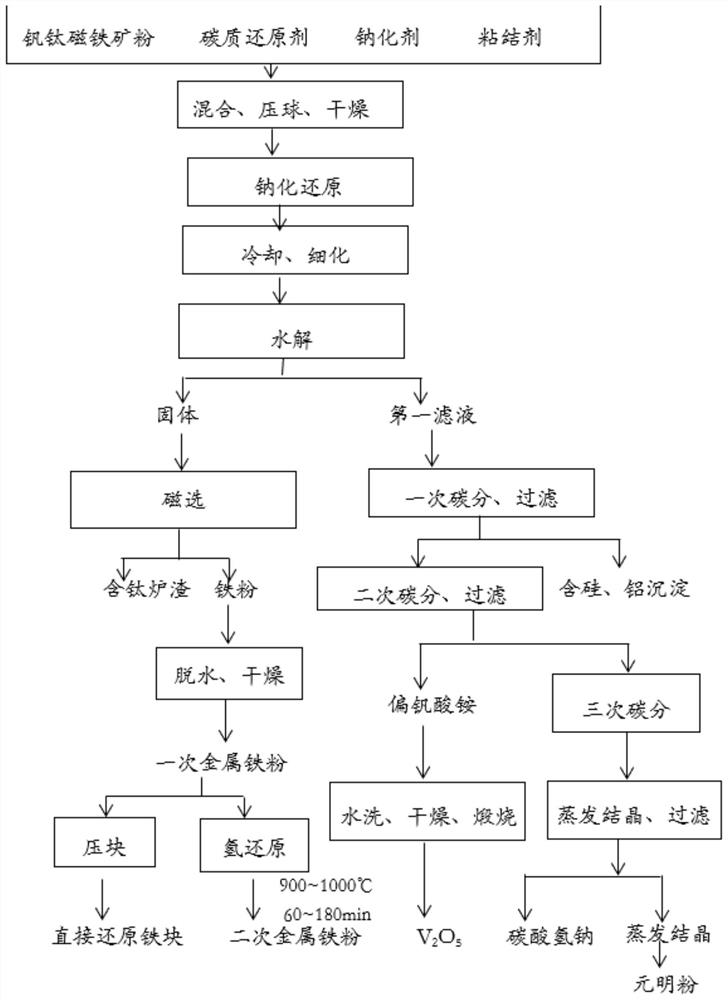

[0084] This embodiment provides a method for realizing the comprehensive utilization of iron, vanadium and titanium by low-temperature reduction roasting of vanadium-titanium magnetite. Using the above-mentioned method, the process flow chart is as follows figure 1 shown. The specific details are as follows:

[0085] The main components of the vanadium-titanium magnetite fine powder used in this embodiment are shown in Table 1; the main components of the coal powder used as a reducing agent are shown in Table 2; Binder.

[0086] Vanadium-titanium magnetite fine powder, carbonaceous reducing agent, sodium bicarbonate, and binder are mixed according to the mass ratio of 100:18:31:5, mixed, and cold-pressed to obtain pellets. The pellets are ellipsoids with a particle size of 35 ~ 50mm. Dry on a continuous dryer, the drying air temperature is 300°C, stay for 30min, and the moisture content of the pellets is 1.8%.

[0087] The pellets enter the heating reduction device for sod...

Embodiment 2

[0095] This embodiment provides a method for realizing the comprehensive utilization of iron, vanadium and titanium by low-temperature reduction roasting of vanadium-titanium magnetite. Using the above-mentioned method, the process flow chart is as follows figure 1 shown. The details are as follows:

[0096] The main components of vanadium-titanium magnetite fine powder used in this embodiment are shown in Table 3; the coal powder used as reducing agent is shown in Table 4; the sodium bicarbonate agent is sodium bicarbonate with a purity greater than 95%, and the binder is an organic binder.

[0097] Vanadium-titanium magnetite fine powder, carbonaceous reducing agent, sodium bicarbonate, and binder are mixed according to the mass ratio of 100:21:48:8, mixed, and cold-pressed to obtain pellets. The pellets are ellipsoids with a particle size of 30-40mm. The pellets are dried on a continuous dryer, the drying air temperature is 300°C, the drying time is 30 minutes, and the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com