Miniature gas chromatographic column capable of using air as carrier gas and manufacturing method thereof

A technology of micro gas chromatography and production method, which is applied in the separation of complex multi-component organic compound gas, high reliability micro gas chromatography column, and high resolution field, which can solve the problem of increasing the coating area of stationary phase, poor stability, and insufficient separation performance and other problems, to achieve the effect of increasing the coating surface area, increasing the roughness of the inner wall, and better thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

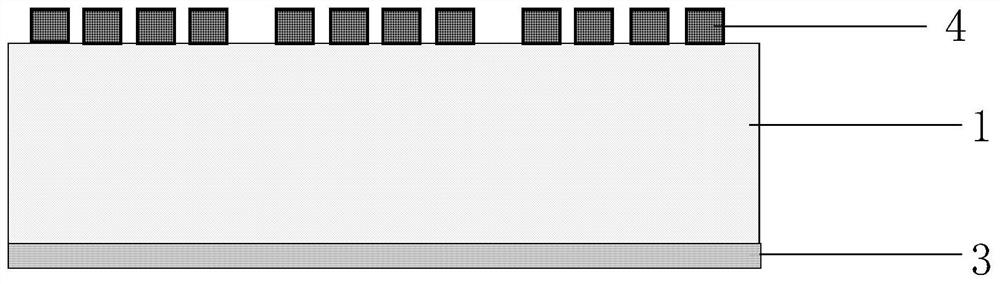

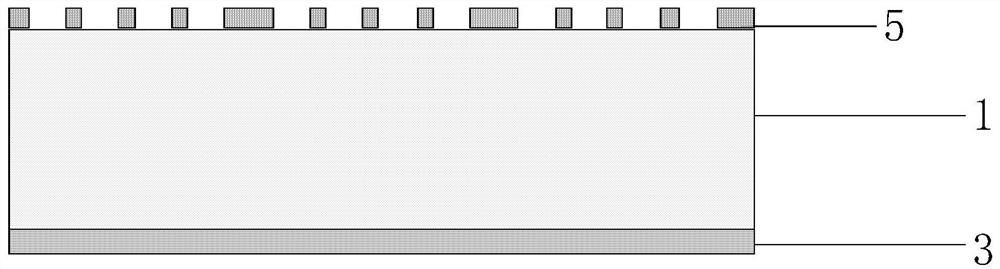

[0074] Step 1) Perform photolithography on a 4-inch 500nm thick N-type double-sided polished and single-sided oxidized silicon wafer 1, and form a 160nm thick aluminum mask layer 5 by electron beam evaporation and stripping.

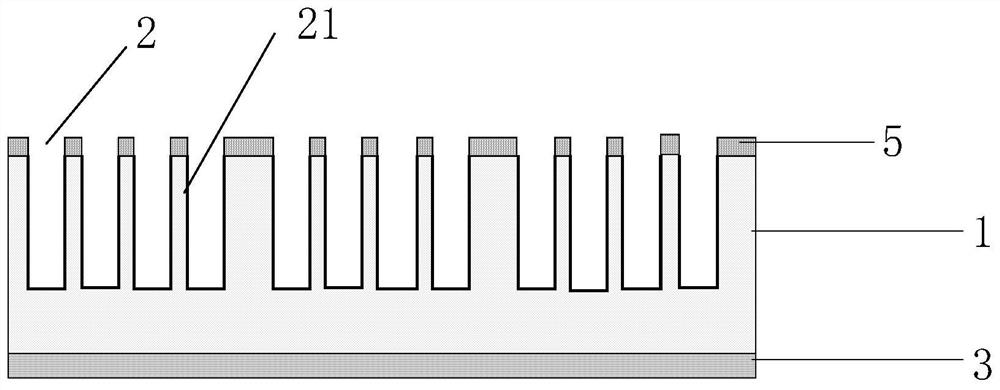

[0075] In step 2), using aluminum as a mask, the chromatographic column microchannel 2 is formed by a deep reactive ion etching method. The size of the microchannel of the chromatographic column is: total length 3m; width 200um; depth 250um; microcolumn arrays are regularly arranged in the microchannel of the chromatographic column, the column cross section is circular, the diameter is 30um, and the spacing on the flow velocity section is 26um. The distance from the wall in the direction of vertical flow velocity is 29um.

[0076] Step 3), use concentrated sulfuric acid with a mass ratio of 60°C: water: nitric acid = 16:4:1 mixed solution and a mixed solution with a mass ratio of concentrated sulfuric acid: hydrogen peroxide = 3:1 to soak and clean the m...

Embodiment 2

[0096] Step 1) Perform photolithography on a 4-inch 600nm thick N-type double-sided polished and single-sided oxidized silicon wafer 1, electron beam evaporation and stripping to form an aluminum mask layer 5 with a thickness of 150nm.

[0097] In step 2), using aluminum as a mask, the chromatographic column microchannel 2 is formed by a deep reactive ion etching method. The size of the column microchannel is as follows: the total length is 1m; the width is 200um; the depth is 100um; the microcolumn array is regularly arranged in the column microchannel, the cross section of the column is square, the side length is 30um, and the spacing on the flow velocity section is 25um, 30um away from the wall in the direction of vertical flow velocity.

[0098] Step 3), use concentrated sulfuric acid with a mass ratio of 60°C: water: nitric acid = 16:4:1 mixed solution and a mixed solution with a mass ratio of concentrated sulfuric acid: hydrogen peroxide = 3:1 to soak and clean the micro...

Embodiment 3

[0117] Step 1) Perform photolithography on a 4-inch 800nm thick N-type double-sided polished and single-sided oxidized silicon wafer 1, and form a 170nm aluminum mask layer 5 by electron beam evaporation and stripping.

[0118] In step 2), using aluminum as a mask, the chromatographic column microchannel 2 is formed by a deep reactive ion etching method. The size of the microchannel of the chromatographic column is: total length 3m; width 200um; depth 300um; microcolumn arrays are regularly arranged in the microchannel of the chromatographic column, the cross section of the column is circular, the diameter is 30um, and the spacing on the flow velocity section is 25um , 30um away from the wall in the direction of vertical flow velocity.

[0119] Step 3), use concentrated sulfuric acid with a mass ratio of 60°C: water: nitric acid = 16:4:1 mixed solution and a mixed solution with a mass ratio of concentrated sulfuric acid: hydrogen peroxide = 3:1 to soak and clean the microcha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com