Carbon monoxide segmented heat transfer half-reaction shift process capable of adjusting water-gas ratio and used for carbonyl synthesis

A carbonylation and carbon monoxide technology, which is applied in the chemical industry, hydrogen/synthesis gas production, sustainable manufacturing/processing, etc., can solve the problems of difficult control means, increased reaction depth, overtemperature, etc., to ensure medium and high pressure Effects of steam production, life extension, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

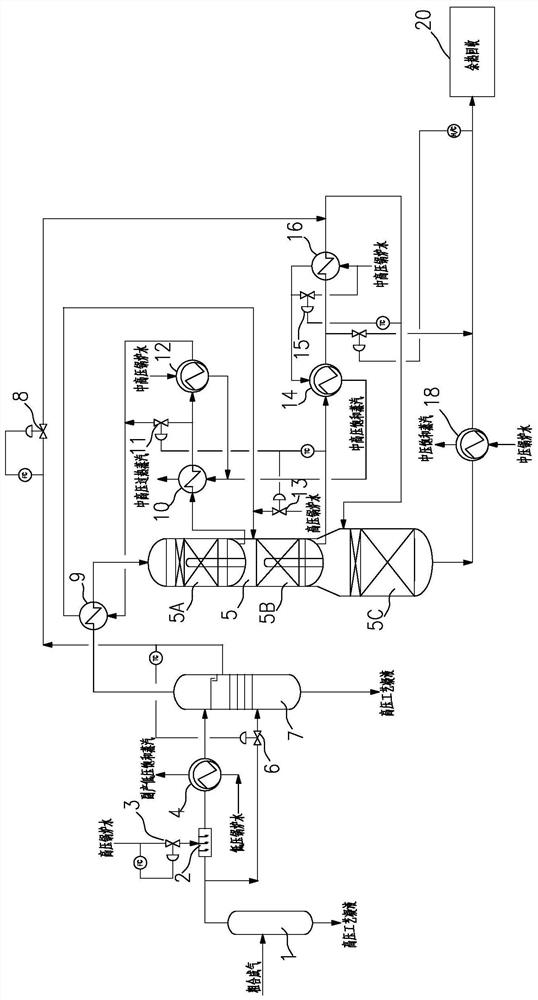

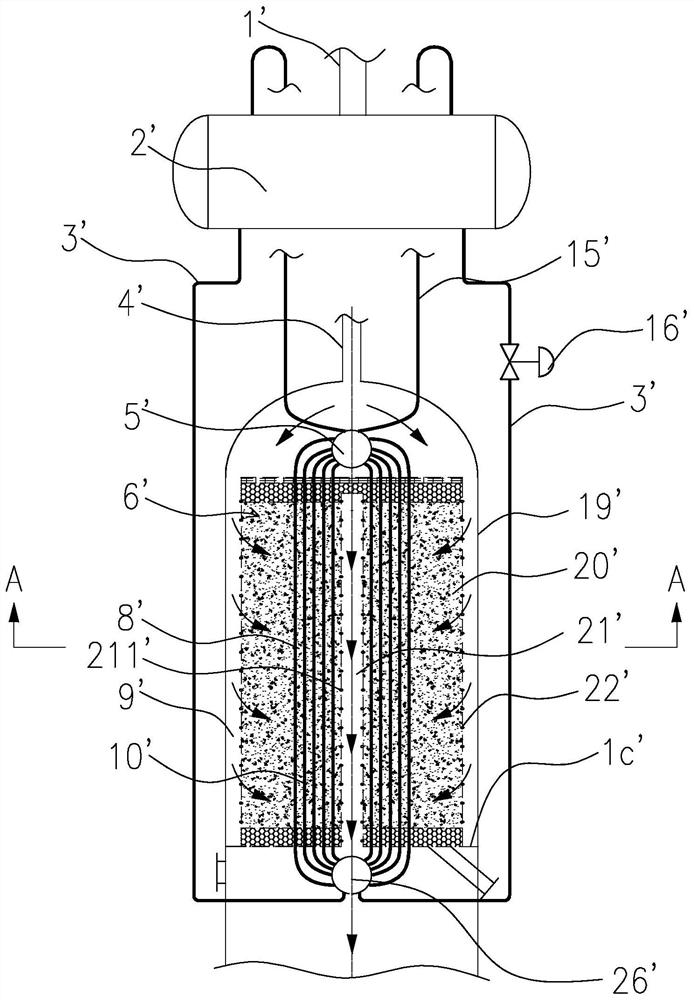

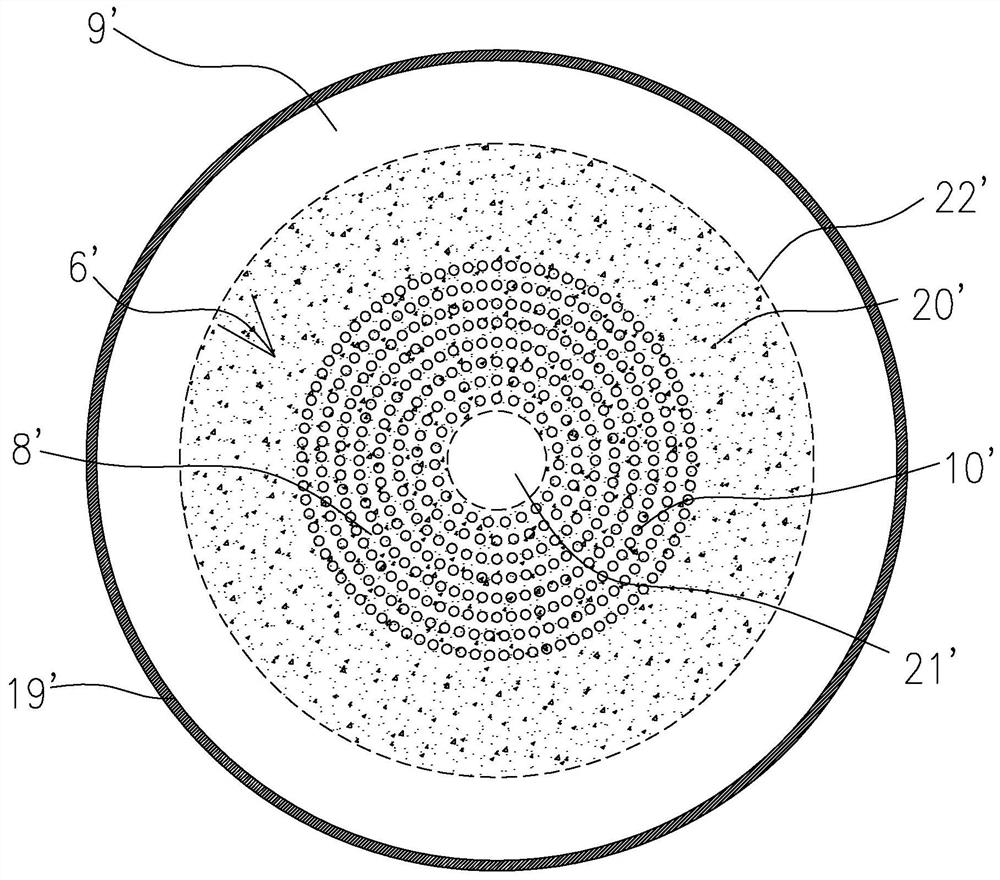

[0041] like Figure 4 As shown, the carbon monoxide staged heat transfer and semi-reaction conversion process for oxo synthesis that can adjust the water-gas ratio in this embodiment adopts the following methods: Figure 4 The reaction system shown includes gas-liquid separator 1, mixer 2, washing boiler water control valve 3, low-pressure steam generator 4, staged heat transfer converter 5, crude synthesis gas bypass control valve 6, high-pressure condensing Liquid separation tower 7, non-shifted gas bypass regulating valve 8, crude synthesis gas heater 9, medium and high pressure steam superheater 10, medium and high pressure steam generator bypass control valve 11 in stage I, medium and high pressure steam generator I12, stage II Inlet high pressure boiler water control valve 13, medium and high pressure steam generator II14, medium and high pressure boiler water preheater bypass control valve 15, medium and high pressure boiler water preheater 16, stage III bypass control ...

Embodiment 2

[0061] The difference between this embodiment and embodiment 1 is: as figure 1 As shown, when the requirements for organic sulfur content in the downstream are not particularly high, the process can also be simplified and the hydrolysis tank can be eliminated.

Embodiment 3

[0063] like figure 1 As shown, this embodiment is used in a device for producing methanol by pulverized coal gasification in a chilling process. The crude synthesis gas from the upstream gasification unit has a temperature of 206°C, a pressure of 3.84MPaG, a carbon monoxide dry basis content of 70%, and a water-gas ratio of 0.9. First enter the raw gas separator 1 for preliminary liquid separation, and then divide it into two streams: one stream of 60% crude synthesis gas is sprayed into a small amount of boiler water from the washing boiler water control valve 3 through the mixer, and enters the low-pressure steam generator 4 by-product The 0.8MPaG low-pressure saturated steam enters the upper layer of the high-pressure condensate separation tower 7; another 40% crude synthesis gas enters the lower layer of the high-pressure condensate separator tower 7 through the crude synthesis gas bypass control valve 6. The crude synthesis gas coming out from the top of the high-pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com