Preparation method of cassava residue/polyvinyl alcohol semi-penetrating network super absorbent microspheres

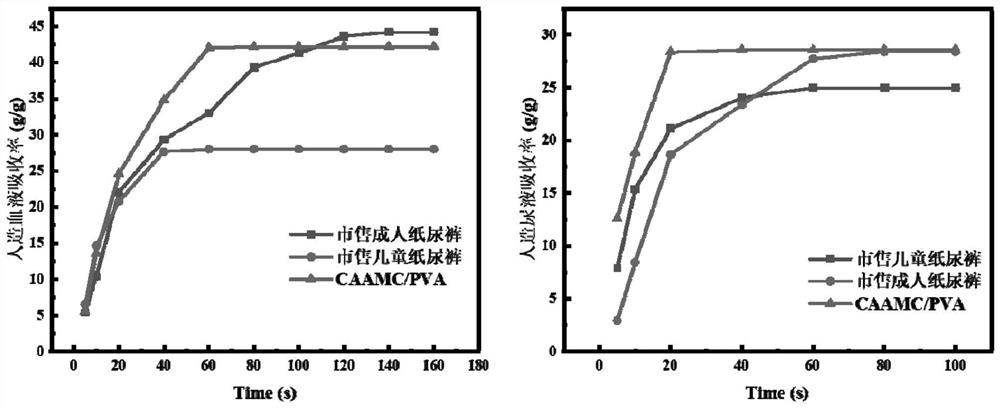

A technology of polyvinyl alcohol and cassava dregs, which is applied in the field of superabsorbent resin preparation, can solve the problems of slow water-absorbing materials, etc., and achieve the effects of increasing water absorption speed, low viscosity of the system, and promoting sustainable development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Cassava residue pretreatment: The cassava residue (CR) is mechanically crushed and passed through a 50-mesh sieve. Weigh 100 parts of sieved cassava residue and 80 parts of sodium hydroxide into a beaker, then measure 2000 parts of ionized water into the beaker, stir and react in a constant temperature water bath at 80°C for 2 hours, after the reaction is completed, take out the reaction solution and centrifuge and wash until neutral The above-mentioned cassava residue and 25 parts of sodium hydroxide, 20 parts of sodium bicarbonate are poured into the large beaker together, adding 1000 parts of deionized water, and then 75 parts of glacial acetic acid. Mechanically stir and react at 80°C for 6 hours, take out the centrifuge and wash the paint until it is neutrally dry, and then pulverize to obtain the treated cassava residue.

[0029] (2) Preparation of modified bentonite: Weigh 1 part of bentonite and 50 parts of ethyl acetate into a beaker, stir ultrasonically fo...

Embodiment 2

[0036] (1) Cassava residue pretreatment: The cassava residue (CR) is mechanically crushed and passed through a 50-mesh sieve. Weigh 100 parts of sieved cassava residue and 80 parts of sodium hydroxide into a beaker, then measure 2000 parts of ionized water into the beaker, stir and react in a constant temperature water bath at 80°C for 2 hours, after the reaction is completed, take out the reaction solution and centrifuge and wash until neutral The above-mentioned cassava residue and 25 parts of sodium hydroxide, 20 parts of sodium bicarbonate are poured into the large beaker together, adding 1000 parts of deionized water, and then 75 parts of glacial acetic acid. Mechanically stir and react at 80°C for 6 hours, take out the centrifuge and wash the paint until it is neutrally dry, and then pulverize to obtain the treated cassava residue.

[0037] (2) Preparation of modified bentonite: Weigh 1 part of bentonite and 50 parts of ethyl acetate into a beaker, stir ultrasonically fo...

Embodiment 3

[0044] (1) Cassava residue pretreatment: The cassava residue (CR) is mechanically crushed and passed through a 50-mesh sieve. Weigh 100 parts of sieved cassava residue and 80 parts of sodium hydroxide into a beaker, then measure 2000 parts of ionized water into the beaker, stir and react in a constant temperature water bath at 80°C for 2 hours, after the reaction is completed, take out the reaction solution and centrifuge and wash until neutral The above-mentioned cassava residue and 25 parts of sodium hydroxide, 20 parts of sodium bicarbonate are poured into the large beaker together, adding 1000 parts of deionized water, and then 75 parts of glacial acetic acid. Mechanically stir and react at 80°C for 6 hours, take out the centrifuge and wash the paint until it is neutrally dry, and then pulverize to obtain the treated cassava residue.

[0045] (2) Preparation of modified bentonite: Weigh 1 part of bentonite and 50 parts of ethyl acetate into a beaker, stir ultrasonically fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com