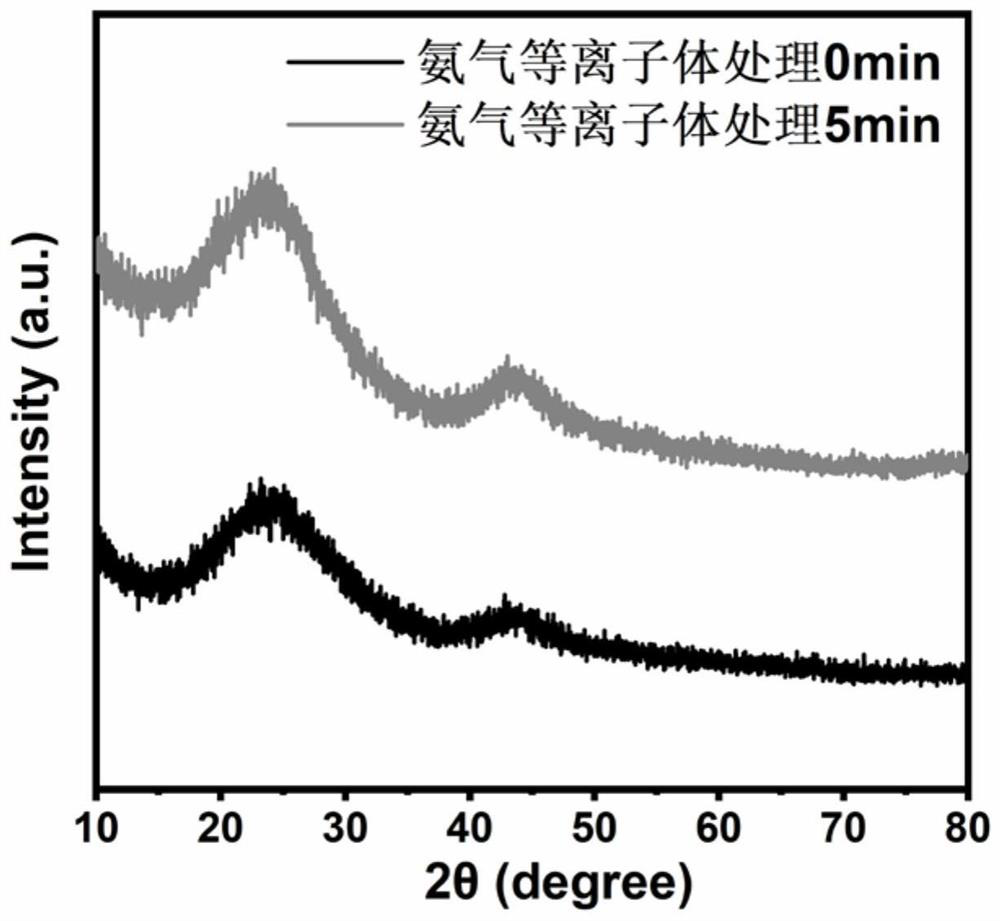

Nitrogen-doped hard carbon material and preparation method and application thereof

A nitrogen-doped, hard carbon technology, used in carbon preparation/purification, electrical components, electrochemical generators, etc., can solve the problems of limited development, unfavorable promotion, high reaction temperature and economic cost, and reduce charge transfer resistance. , the effect of promoting diffusion and improving electrode kinetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

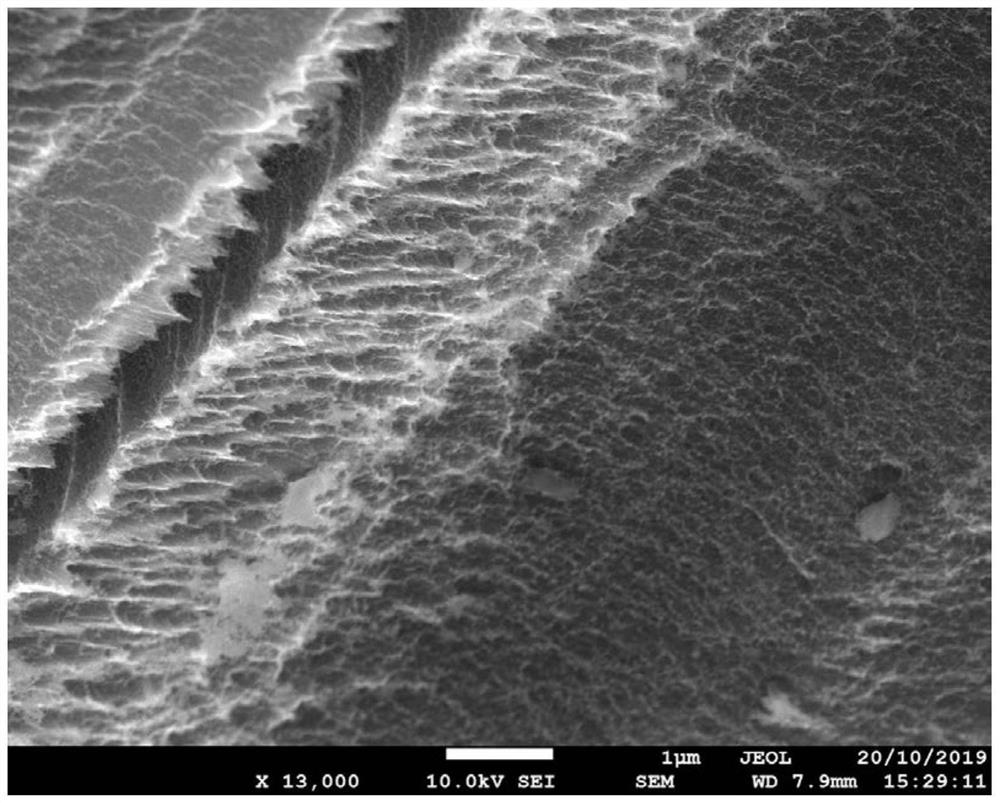

[0039] A method for preparing a nitrogen-doped hard carbon material, comprising the following steps:

[0040]S1. Carbon source preparation (primary purification): select pomelo peel as the precursor carbon source, remove the inner and outer skins, take the main woody part, wash it with distilled water three times, dry it in an oven at 120°C for 24 hours, and then use a high-energy The pulverizer is pulverized at a speed of 6000r / min for 5min, and 325 mesh pomelo peel powder is screened out;

[0041] S2, secondary purification: take by weighing the pomelo peel powder in 100g step S1 and place in the round bottom flask, under the reflux condensation operation of condensed water, add the dilute nitric acid that concentration is 10wt% in the round bottom flask, then in the oil bath pan reflux at 80°C for 1 hour, finally filter, wash with distilled water three times, and dry in an oven at 120°C for 24 hours to obtain secondary purified pomelo peel powder;

[0042] S3. Calcination:...

Embodiment 2

[0045] A method for preparing a nitrogen-doped hard carbon material, comprising the following steps:

[0046] S1. Carbon source preparation (primary purification): select pomelo peel as the carbon source of the precursor, remove the inner and outer skins, take the main woody part, wash it with distilled water three times, dry it in an oven at 120°C for 24 hours, and then use high-energy pulverization The machine was crushed at a speed of 6000r / min for 5 minutes, and 325-mesh pomelo peel powder was screened out;

[0047] S2, secondary purification: take by weighing the pomelo peel powder in 100g step S1 and place in the round bottom flask, under the reflux condensation operation of condensed water, add the dilute nitric acid that concentration is 10wt% in the round bottom flask, then in the oil bath pan Reflux at a temperature of 80° C. for 1 h, and finally filter, wash with distilled water three times, and dry in an oven at 120° C. for 24 h to obtain secondary purified pomelo ...

Embodiment 3

[0051] A method for preparing a nitrogen-doped hard carbon material, comprising the following steps:

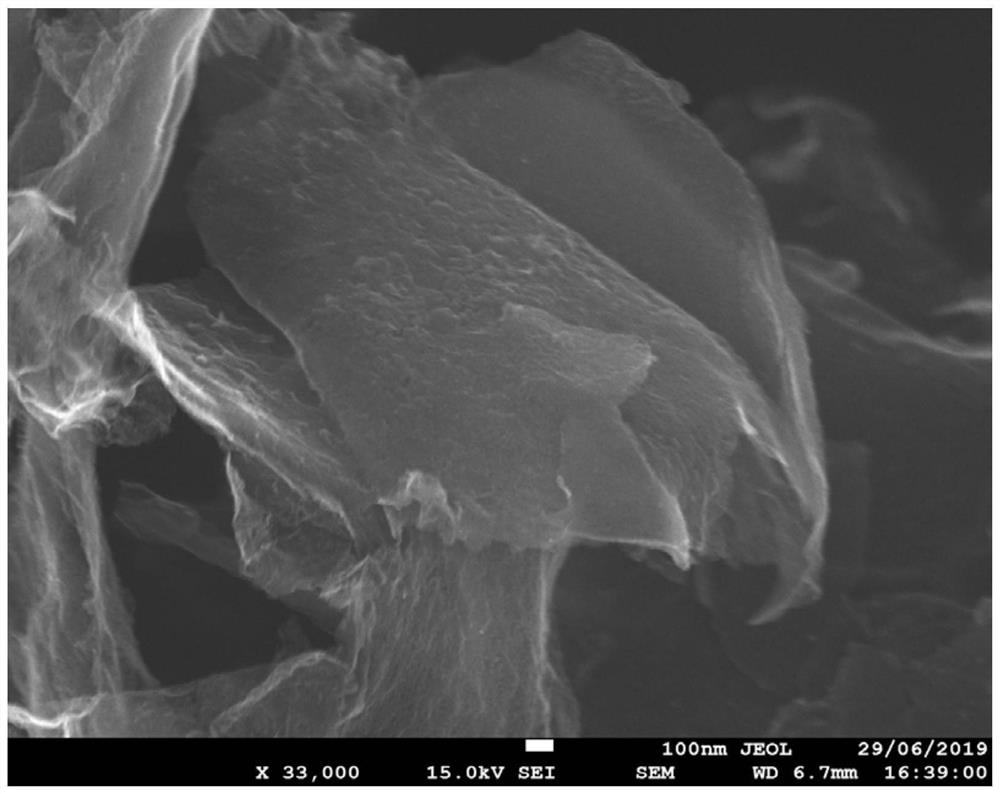

[0052] S1. Carbon source preparation (primary purification): select durian shell as the precursor carbon source, peel it, take its woody main part, wash it with distilled water three times, dry it in an oven at 120°C for 24 hours, and then use a high-energy pulverizer Grinding at a speed of 8000r / min for 10 minutes, and sifting out 325-mesh durian shell powder;

[0053] S2, secondary purification: take by weighing the durian shell powder in 100g step S1 and place in the round-bottomed flask, under the reflux condensation operation of condensed water, add the dilute nitric acid that concentration is 10wt% in the round-bottomed flask, then in the oil bath pan reflux at 80°C for 1 hour, finally filter, wash with distilled water three times, and dry in an oven at 120°C for 24 hours to obtain durian shell powder after secondary purification;

[0054] S3. Calcination: Weigh 30 g o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com