Preparation method of halcinonide and intermediate thereof

A compound, N-7 technology, applied in the field of preparation of halcyonide and its intermediates, can solve the problems of product quality and yield need to be improved, strong irritation, large energy consumption, etc., so as to shorten the production cycle and simplify the production Steps, the effect of reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

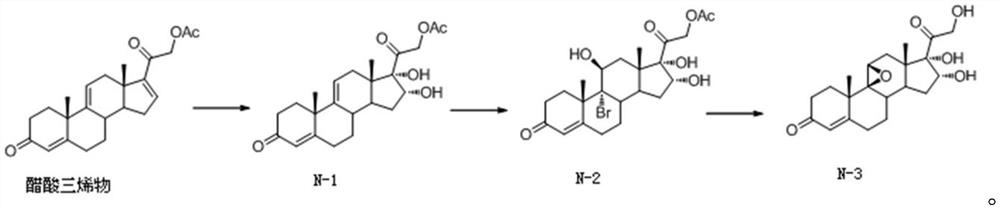

[0048] The preparation of embodiment 1 intermediate N-3

[0049] This embodiment provides the preparation method of the compound of intermediate formula N-3, the steps are as follows:

[0050] Step A: Preparation of intermediate N-1 from triene acetate

[0051] Add 8.1g of potassium permanganate to 105ml of water, heat up to 40°C, stir to dissolve potassium permanganate, add 300ml of acetone after dissolving, stir and cool down to about -5°C to obtain potassium permanganate solution; set aside.

[0052] Add 9g of sodium sulfite into 75ml of water, stir and dissolve to obtain sodium sulfite solution; set aside.

[0053] Add 15g of triene acetate to 600ml of acetone, cool down to about -5°C, add 5.4ml of formic acid, stir for 5 minutes, add the potassium permanganate solution prepared above, control the temperature at -5°C for 10 minutes, add the prepared The sodium sulfite solution was heated to 40°C, filtered, and the filtrate was concentrated under reduced pressure to be fr...

Embodiment 2

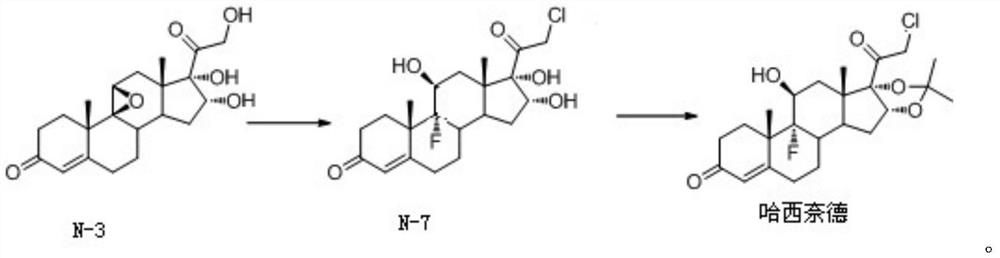

[0059] The preparation of embodiment 2 halcinonide

[0060] This embodiment provides the preparation method of halcinonide, the steps are as follows:

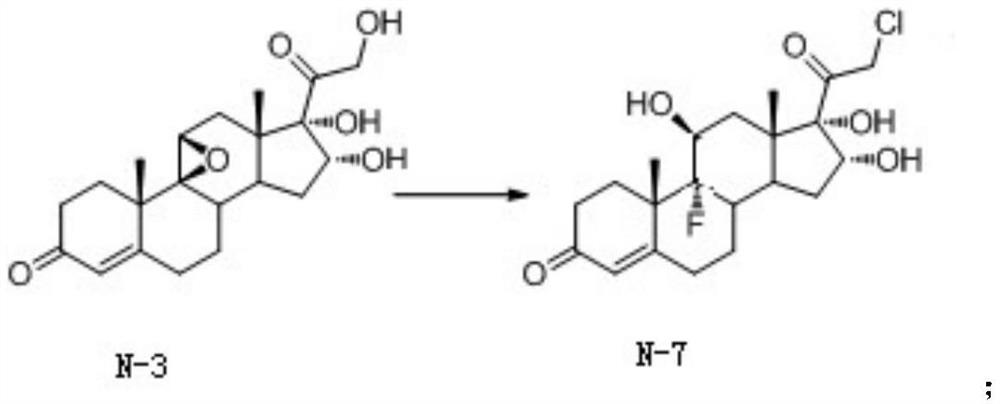

[0061] Step A: Preparation of Intermediate N-7

[0062] Dissolve 60g of potassium hydroxide in 300ml of water, stir and dissolve to obtain potassium hydroxide solution; set aside.

[0063] Under the protection of nitrogen, add 160ml of chloroform, 20g of the compound of formula N-3 and 20g of p-toluenesulfonyl chloride into the reaction flask, cool down to about -5°C, add 25ml of diethylamine dropwise, drop it in 30 minutes, and then - React at about 5°C for 5 hours, TLC (dichloromethane: acetone = 6:1) detects almost no spots at Rf 0.35, add 2ml of methanol, heat up to about 30°C, keep warm for 10 hours, TLC (dichloromethane: acetone =6:1) There is almost no spot at Rf 0.65, washed twice with 100ml of drinking water, the organic layer is cooled to below 10°C, under the protection of nitrogen, add 1g of antioxidant BHT, conti...

Embodiment 3

[0068] The preparation of embodiment 3 halcinonide

[0069] This embodiment provides the preparation method of halcinonide, the steps are as follows:

[0070] Step A: Preparation of Intermediate N-7

[0071] Dissolve 60g of potassium hydroxide in 300ml of water, stir and dissolve to obtain potassium hydroxide solution; set aside.

[0072] Under the protection of nitrogen, add 160ml of dichloromethane, 20g of the compound of formula N-3 and 18g of p-toluenesulfonyl chloride into the reaction flask, cool down to about 0°C, add 25ml of triethylamine dropwise, drop it in 30 minutes, and put it at 0°C React for about 5 hours, TLC (dichloromethane: acetone = 6: 1) detects that there is almost no spot at Rf 0.35, add 2ml of methanol, heat up to about 35 ° C, keep the reaction for 10 hours, TLC (dichloromethane: acetone = 6: 1) There are almost no spots at Rf 0.65, wash twice with 100ml of drinking water, cool the organic layer to below 10°C, add 1g of antioxidant BHT under nitrogen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com