Method for modifying wet base surface of aluminum sulfate cement by using hydrophilic micromolecular epoxy composite resin

A technology of aluminum sulfate cement and composite resin, which is applied in epoxy resin coatings, coatings, anti-corrosion coatings, etc., can solve problems such as insoluble in water, achieve good thermal stability, improve coupling, and physical and mechanical properties Enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1: Preparation of polyetheramine curing agent

[0038] Step 1: Add 109 parts of acrylic acid, 95 parts of 3-methyl-2-buten-1-amine and 0.6 parts of p-benzoquinone and 4,4' in a mass ratio of 1:2 to a reactor equipped with a stirrer - Compositions of biphenyls. Heated to 94°C in an oil bath and reacted for 1 h to prepare the amide monomer.

[0039] Step 2: Add 198 parts of the prepared amide monomer and 100 parts of allyloxypropanol into a reaction kettle equipped with a stirrer, and heat to 83° C. in a water bath. 112 parts of allyloxy propanol and water are prepared into liquid A, 2.79 parts of ammonium persulfate and di-tert-butyl peroxide in a mass ratio of 3:2, 8 parts of mercaptopropane in a mass ratio of 1:4 The composition of acid and mercaptopropanol and water are prepared into liquid B, and liquid A and liquid B are added dropwise to the reaction kettle with a drip pump, wherein liquid A is added dropwise for 1.5 hours, and liquid B is added dropwi...

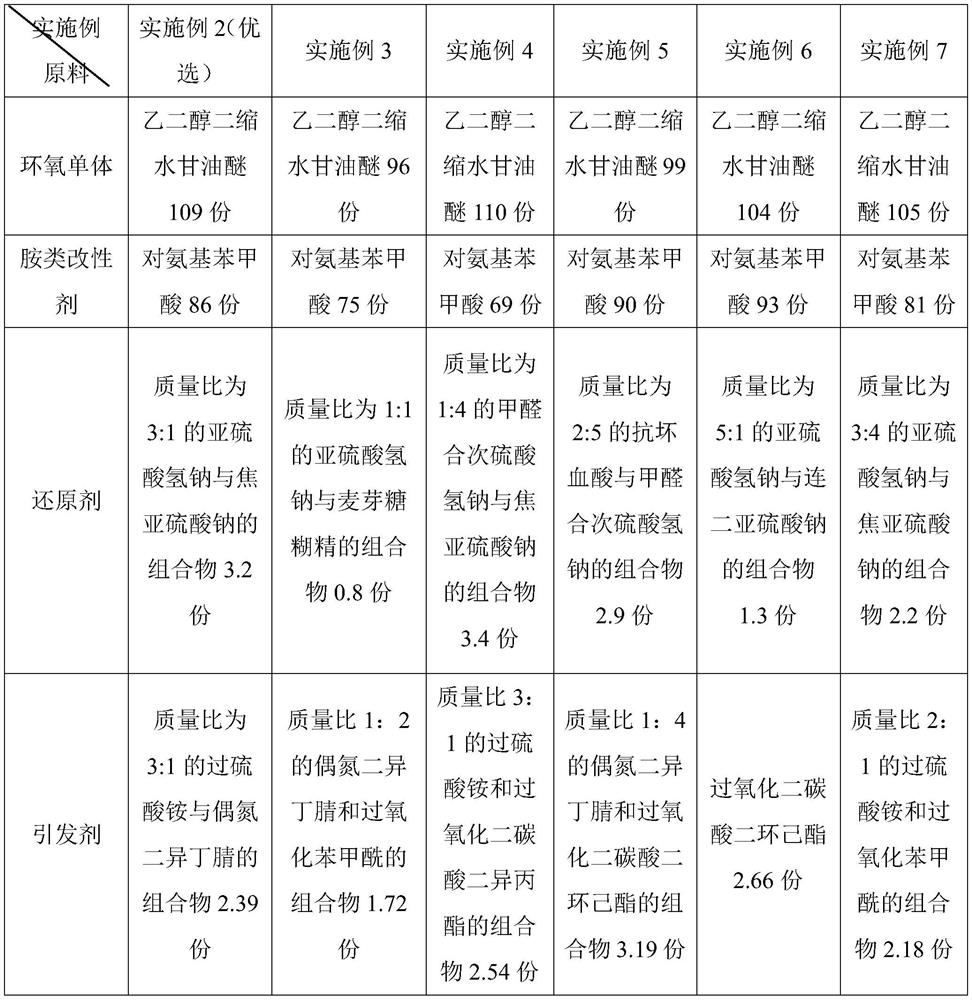

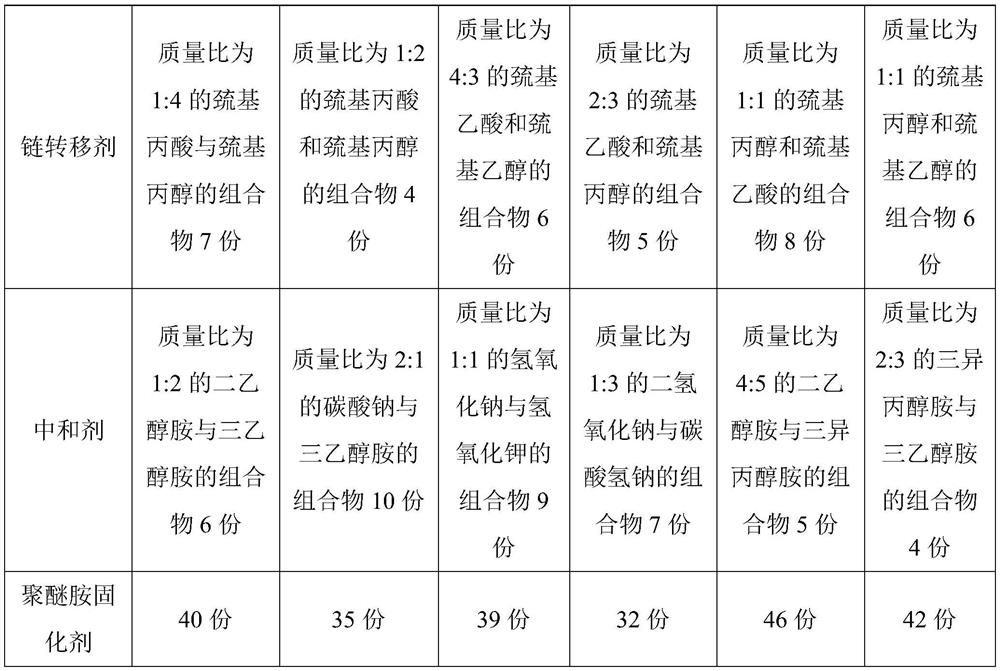

Embodiment 2

[0041] The epoxy composite monomer aqueous solution is formed by polymerizing the following components, the total mass of raw materials is 1000 parts, and each component includes:

[0042] 109 parts of ethylene glycol diglycidyl ether;

[0043] 86 parts of p-aminobenzoic acid;

[0044] 3.2 parts of the composition of sodium bisulfite and sodium metabisulfite with a mass ratio of 3:1;

[0045] 2.39 parts of a composition of ammonium persulfate and azobisisobutyronitrile with a mass ratio of 3:1;

[0046] Mass ratio is 7 parts of the composition of mercaptopropionic acid and mercaptopropanol of 1:4;

[0047] 6 parts of the composition of diethanolamine and triethanolamine whose mass ratio is 1:2;

[0048] 40 parts of polyetheramine curing agent;

[0049] The rest is water.

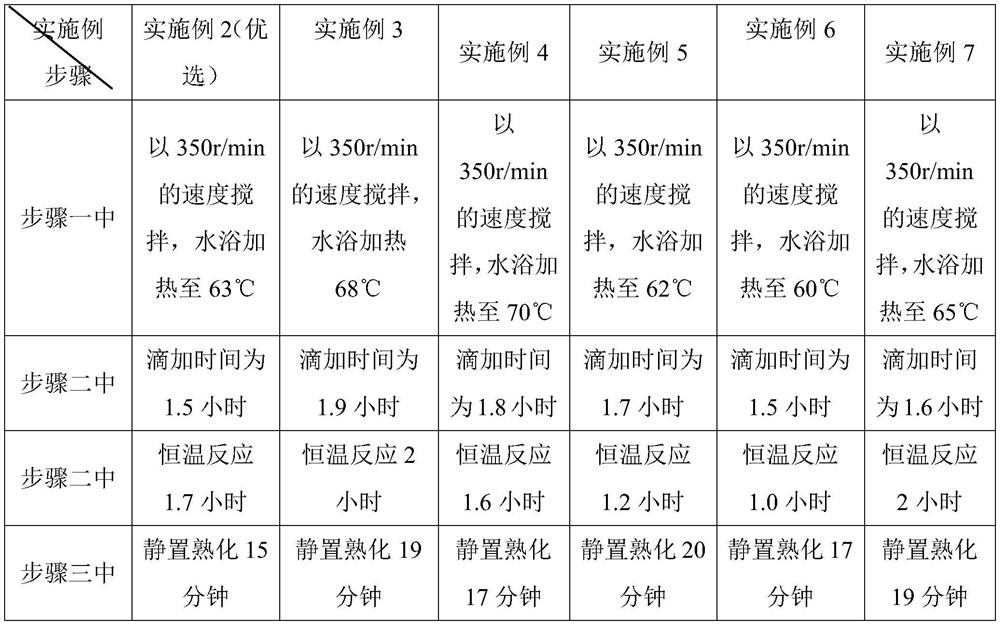

[0050] A method for modifying a wet base surface of aluminum sulfate cement by using a hydrophilic small-molecule epoxy composite resin. The preparation process includes the following steps in sequence: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com