Acetonitrile refining method

A refining method, acetonitrile technology, applied in the direction of separation method, chemical instrument and method, hydrocarbon ammoxidation preparation, etc., can solve the problems of acetonitrile output and output limitation, avoid multiple evaporation and condensation, improve the energy utilization rate of the device, save The effect of equipment occupation and investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

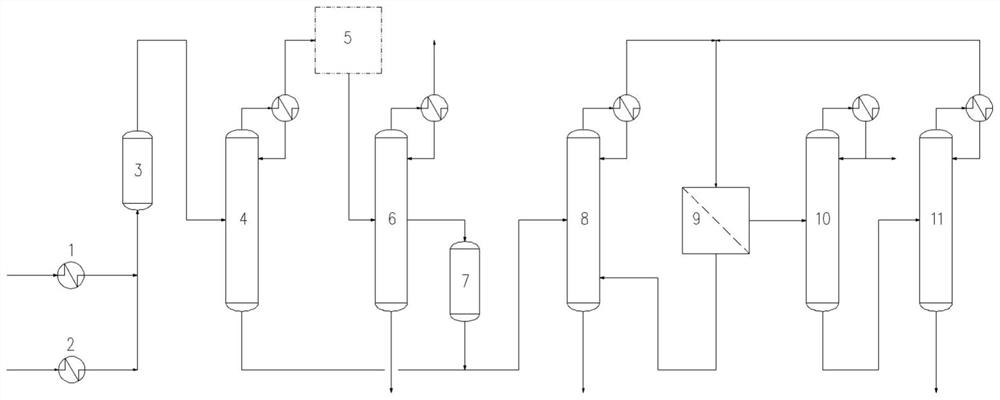

Embodiment 1

[0056] Ammonia and acetic acid are added into the ammoniation reactor 3 to carry out the acetic acid ammoxidation reaction, the molar ratio of ammonia to acetic acid is 1.01, the reaction temperature is 350°C, the gas phase product at the outlet enters the ammonia recovery tower 4, and the tower top pressure is 150kPa, the tower The temperature at the top is -25°C, and ammonia gas is extracted from the gas phase at the top of the tower and sent to the acrylonitrile unit 5.

[0057] The crude acetonitrile obtained through the ammoxidation of propylene is sent to the decyanation tower 6, the pressure at the top of the tower is 105kPa, and the temperature at the top of the tower is 25°C. The acetonitrile-water azeotrope is extracted from the gas phase in the middle of the tower, and enters the purification reactor 7, and the temperature is controlled at 25-55°C.

[0058] The outlet liquid of the purification reactor 7 is mixed with the bottom liquid of the ammonia recovery tower ...

Embodiment 2

[0062] Ammonia and acetic acid are added into the ammoniation reactor 3 to carry out the ammoxidation reaction of acetic acid. The molar ratio of ammonia to acetic acid is 1.99, and the reaction temperature is 350°C. The temperature at the top is 10°C, and ammonia gas is extracted from the gas phase at the top of the tower and sent to the acrylonitrile unit 5.

[0063] The crude acetonitrile obtained through the ammoxidation of propylene is sent to the decyanation tower 6, the pressure at the top of the tower is 110kPa, and the temperature at the top of the tower is 75°C. The acetonitrile-water azeotrope is extracted from the gas phase in the middle of the tower, and enters the purification reactor 7, and the temperature is controlled at 25-55°C.

[0064] The outlet liquid of the purification reactor 7 is mixed with the bottom liquid of the ammonia recovery tower 4 and then enters the azeotropic tower 8, and the pressure at the top of the tower is 500kPa. The acetone-containi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com