Solid waste-based in-furnace synchronous desulfurization and denitrification agent as well as preparation method and application thereof

A desulfurization, denitrification and internal synchronization technology, applied in separation methods, combustion methods, chemical instruments and methods, etc., can solve problems such as desulfurization, and achieve the effects of reducing NOx control pressure, reducing ammonia injection, and saving clean water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

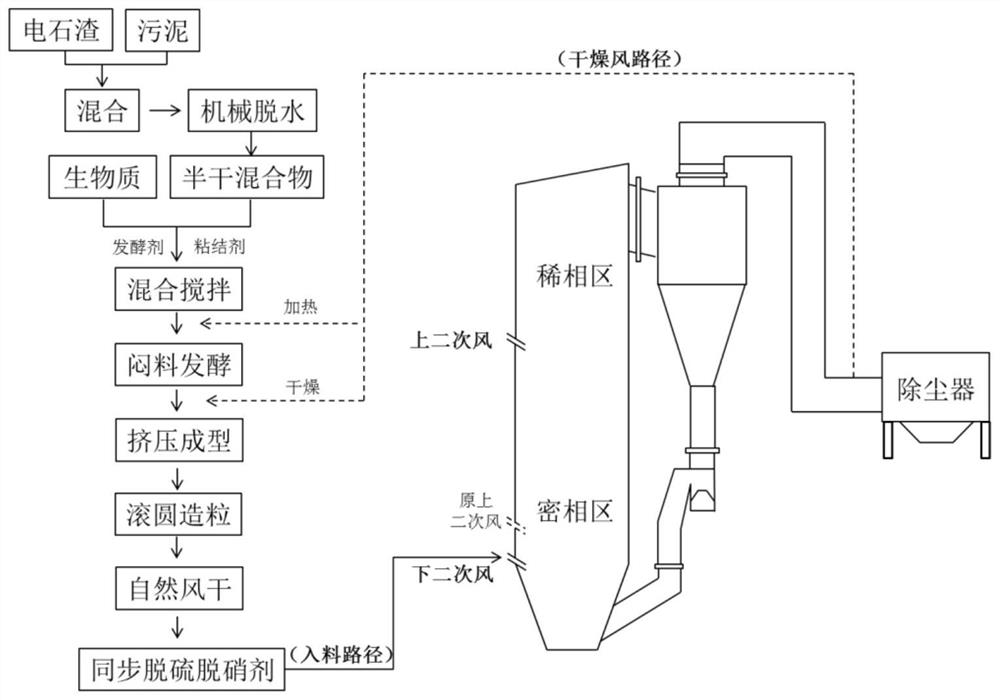

[0037] refer to figure 1 , the preparation method and application of synchronous desulfurization and denitrification agent in the solid waste base furnace, comprising the following steps:

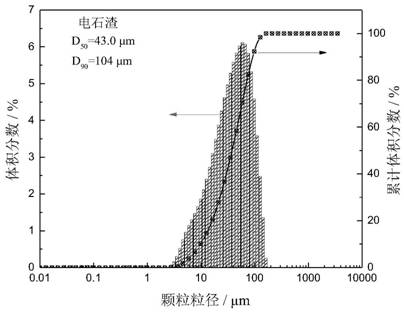

[0038] Step 1: Carbide slag and sludge with a water content of 5% after mechanical dehydration are mixed according to a mass ratio of 7:3 and then mechanically dehydrated to make a mixture of calcium carbide slag and sludge in a semi-dry state with a water content of 40%, and Crushing the biomass into biomass powder with a particle size of 2 mm;

[0039] Step 2, mix the biomass powder and the mixture in step 1 again according to the mass ratio of 2:8, and add quick-drying high-alumina cement binder accounting for 5% of the total mass of the mixture and 0.5% of the total mass of the mixture for fermentation agent, stir it evenly in a stirring tank to obtain a mixture;

[0040] In step 3, the mixture evenly stirred in step 2 is fermented. The fermentation condition is to use the flue gas at...

Embodiment 2

[0046] Preparation of simultaneous desulfurization and denitrification agent in solid waste base furnace

[0047] Take 10g of sludge in a semi-dry state and 90g of calcium carbide slag in a semi-dry state for mixing, add 5g of quick-drying high-alumina cement and 0.5g of starter, and mix the mixture evenly in the mixing tank; Part of the flue gas waste heat at 100°C to 150°C in front of the flue dust collector of the fluidized bed boiler heats the evenly stirred mixture to 30°C for 2 days of stuffing fermentation, and uses part of the waste heat of the flue gas to heat the mixture after fermentation Dry, and control the moisture after drying at 25% to 35%. Then put the mixture into a screw extruder to extrude columns with a diameter of 1.5 mm to 5 mm, cut the column mixture according to the width of 5 mm to 10 mm, and put the segments into a spheronizer to form spherical particles. The spheroidized particles are naturally air-dried, and the water content is controlled at 5% a...

Embodiment 3

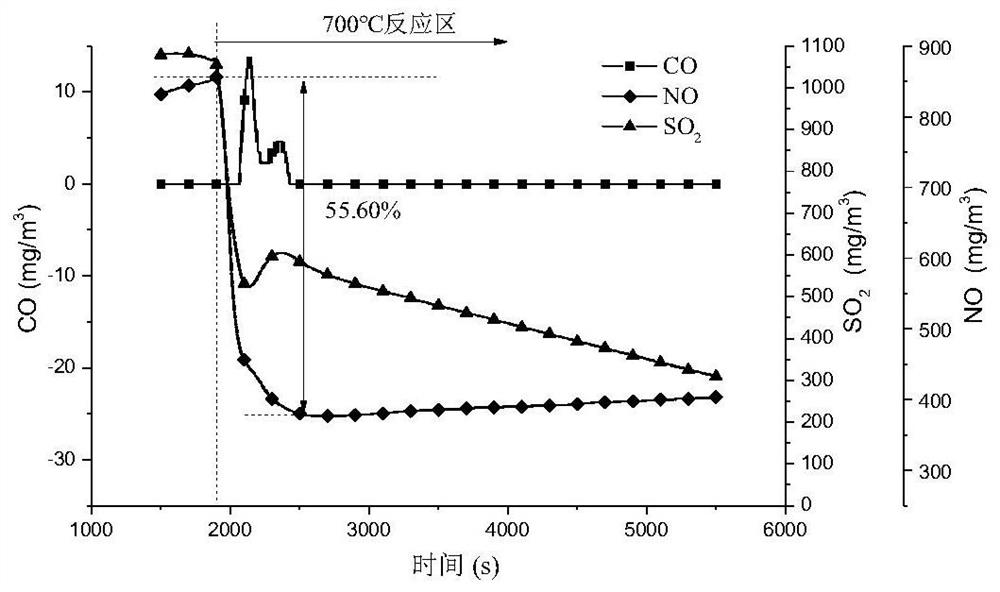

[0049] The use of synchronous desulfurization and denitrification agent in the solid waste base furnace of the present invention

[0050] When the synchronous desulfurization and denitrification agent is used in the furnace, the boiler needs to be modified, and the position of the upper secondary air should be raised to further strengthen the oxygen-poor atmosphere in the furnace. The reduction ability of NOx is also enhanced. Then the synchronous desulfurization and denitrification agent enters from the lower secondary tuyere, where the oxygen concentration is 1% to 3%. Rich pore structure. and here SO 2 Generated, good for shortening SO 2 Response time to concentration reduction. Abundant pore structure enhances SO adsorption on coke surface 2 and NOx, promote coke reduction of NOx and calcium carbide slag and SO 2 gas-solid reaction, effectively reducing SO in the furnace 2 and NOx concentrations.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com