Device and method for preparing ammonia by hydrolyzing urea for flue gas denitrification of thermal power plant

A technology for urea hydrolysis and thermal power plants, which is applied in chemical instruments and methods, separation methods, ammonia compounds, etc. It can solve the problems of slow hydrolysis reaction rate, blockage of urea hydrolysis system, and damage to stainless steel, so as to reduce steam loss and operation cost , the effect of improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, which are explanations rather than limitations of the present invention.

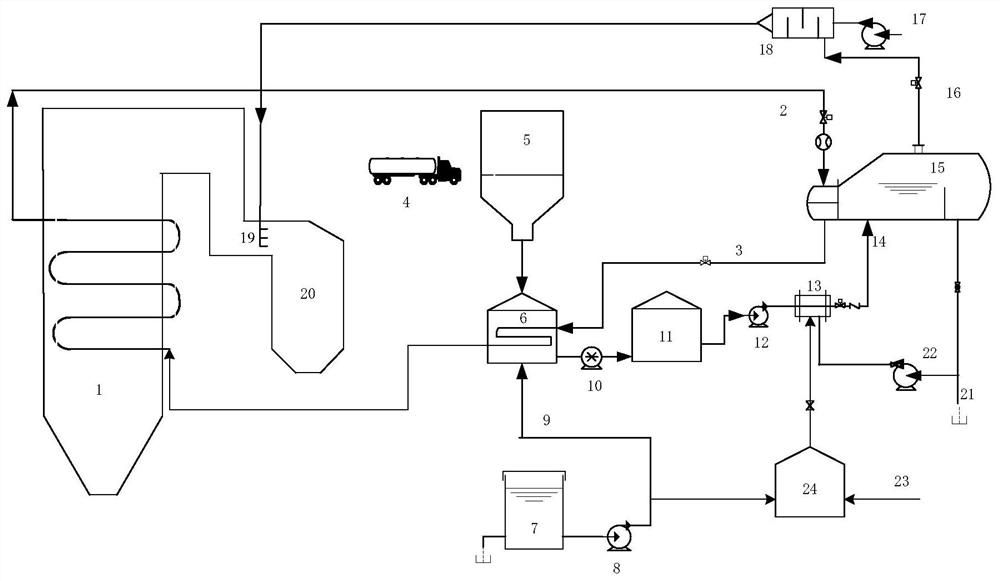

[0029] The invention proposes a urea hydrolysis ammonia production device and ammonia production method for flue gas denitrification in thermal power plants, which are characterized in that the catalyst is used to increase the hydrolysis reaction speed, and the uniformity of the catalyst particle distribution is improved through the circulation of the reaction liquid. The device consists of figure 1 As shown, it is characterized by:

[0030] 1) The bagged urea is transported to the power plant by car and placed in the urea storage bin 5. After the bag is broken, it is sent to the urea dissolving tank 6 by the bucket elevator; The demineralized water pipeline 9 is sent into the urea dissolving tank 6 one way, and the other way is sent into the catalyst storage ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com