Composite electrode material and preparation method and application thereof

A composite electrode and mixed solution technology, which can be used in the manufacture of hybrid capacitor electrodes and hybrid/electric double-layer capacitors, etc., can solve problems such as undiscovered and LDHs agglomeration, and achieve improved cycle stability, fast conductive network, and improved energy density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Preparation of N-GQDs: 0.42 g citric acid and 0.36 g urea were dissolved in 30 mL H 2 Ultrasonic dispersion in O for 2 hours, the mixed solution was transferred to a 50 mL stainless steel autoclave lined with polytetrafluoroethylene, heated at 180 °C for 5 hours; the product was centrifuged at 12000 rpm for 20 minutes, and the supernatant was taken at 80 °C Dried to obtain N-GQD powder, configured to a concentration of 1 mg·mL -1 The N-GQDs aqueous solution is standby;

[0031] (2) Preparation of Ni-MOF / NF: 1.2g Ni(NO 3 )2 •6H 2 O and 2.6 g of 2-methylimidazole (2-MI) were dissolved in 80 mL of distilled water, and the 2-MI aqueous solution was quickly poured into the Ni(NO 3 ) 2 •6H 2 O aqueous solution was stirred for 10 minutes to obtain a mixed solution, and a piece was cut into 1×3cm 2 The nickel foam was put into the mixed solution for aging for 2 hours, washed with water and ethanol several times, and dried at 60°C for 5 hours to obtain Ni-MOF / NF;

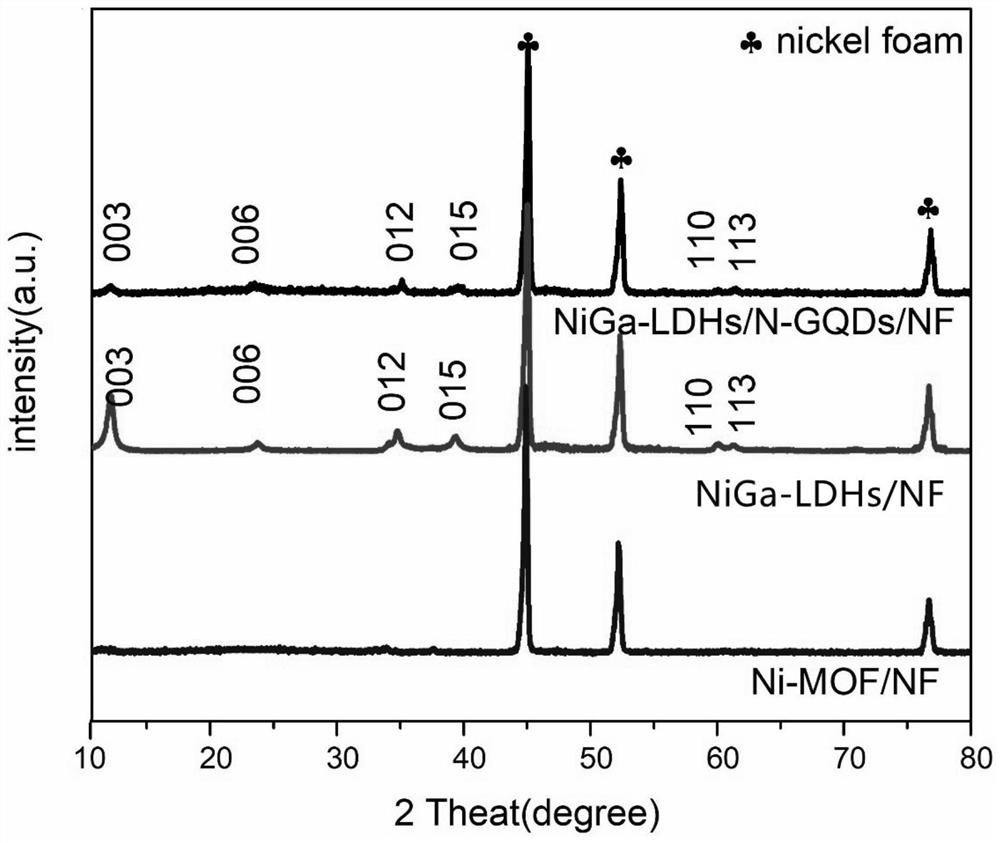

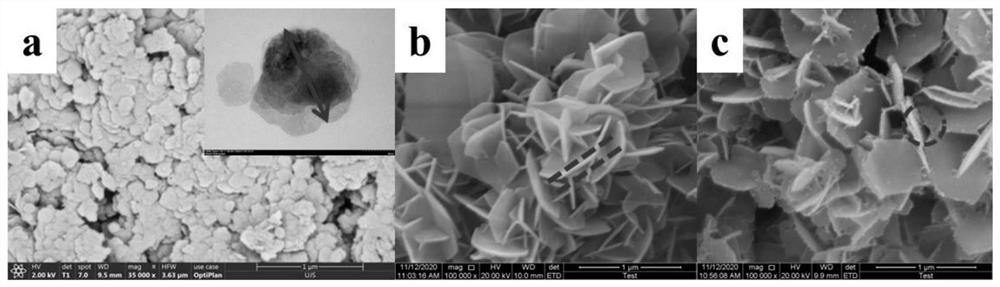

[0...

Embodiment 2

[0037] In this example, under the condition that other conditions remain unchanged, a comparative experiment is established to prepare NiGa-LDHs / N-GQDs-x / NF with different additions of N-GQDs, where x is the concentration of N-GQDs aqueous solution. The comparison experiment was the same as the preparation method described in Example 1, except that the concentration of the N-GQDs aqueous solution in step (3) was changed from 1 mg·mL -1 Replaced with 2, 3, 4 and 5 mg·mL, respectively -1 .

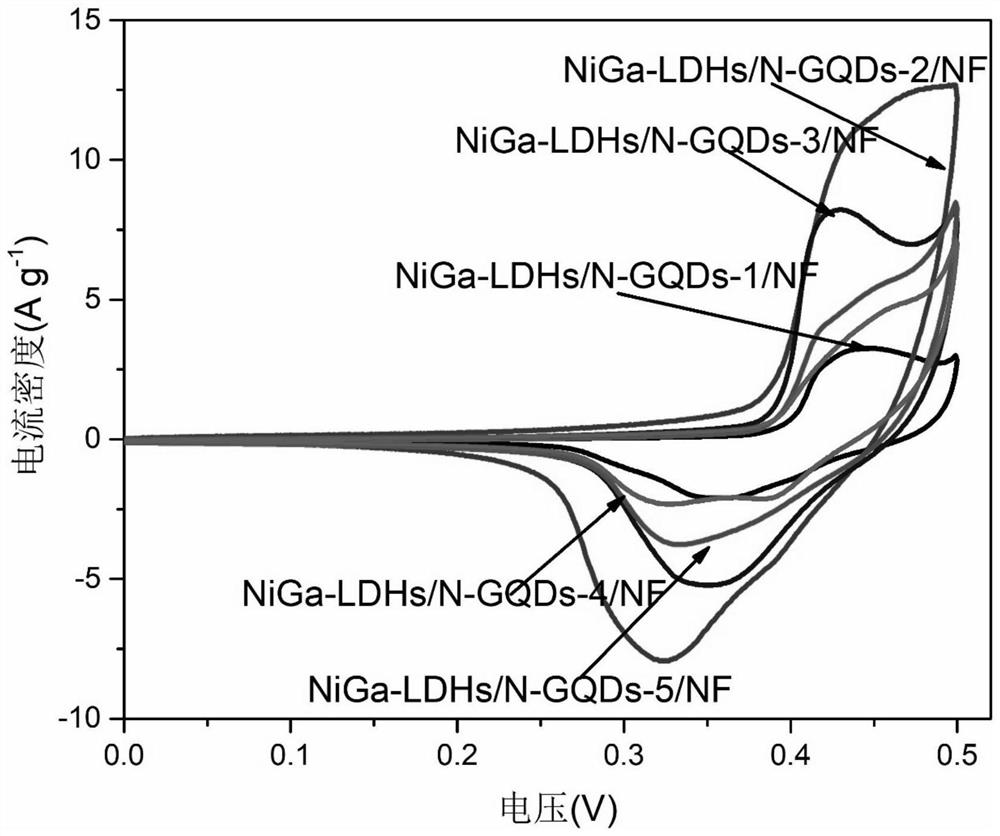

[0038] image 3 It is the CV figure of NiGa-LDHs / N-GQDs-x / NF prepared in embodiment 2; Figure 4 is the GCD diagram of Ni-MOF, NiGa-LDHs and NiGa-LDHs / N-GQDs-x / NF; from image 3 It can be seen that when the concentration of N-GQDs aqueous solution is 2 mg·mL -1 The performance of NiGa-LDHs / N-GQDs-2 / NF prepared at this time is the best. Depend on Figure 4 It can be seen that compared with the others, the discharge time of the prepared NiGa-LDHs / N-GQDs-2 / NF is the longest. After the cap...

Embodiment 3

[0040] In this example, Co-MOF derived carbon nanosheets (Carbon NSs) supported on carbon cloth were prepared. 0.004mol Co(NO 3 ) 2 •6H 2 O and 0.032 mol 2-MI were dissolved in 80 mL distilled water respectively, and the 2-MI aqueous solution was quickly poured into Ni(NO 3 ) 2 •6H 2 O aqueous solution was stirred for 10 minutes to obtain a mixed solution, and then cut into 1 × 3 cm 2 The carbon cloth was aged in the above mixed solution for 2 hours, washed with water and ethanol several times, dried at 60°C for 5 hours, and the obtained Co-MOF was dried at 5°C min -1 Heated to 930°C for 2 hours to prepare Co-MOF derived carbon nanosheets. The obtained Co-MOF-derived carbon nanosheets were used as anodes for asymmetric supercapacitors. The evaluation of electrochemical performance was carried out in the CHI660e electrochemical workstation (purchased from Shanghai Chenhua Instrument Co., Ltd.). Under the three-electrode system, the NiGa-LDHs / N-GQDs / NF electrode material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com