Preparation method and application of molybdenum disulfide nano dot hybrid nano-filtration membrane

A molybdenum disulfide, nano-dot technology, applied in chemical instruments and methods, membrane, membrane technology and other directions, can solve the problems of ecological environment and water damage, affecting the normal growth of vegetation, high processing cost, and achieve smooth surface flow resistance characteristics, Realize the effect of efficient resource processing and high separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Preparation of MoS 2 Nano dot hybrid nanofiltration membrane, the steps are as follows:

[0033] 1) Put the polyacrylonitrile ultrafiltration membrane into a sodium hydroxide solution with a concentration of 1 mol / L, control the temperature at 50°C for heat treatment for 1 h, and then rinse the surface of the membrane with distilled water to obtain a hydrolyzed polyacrylonitrile ultrafiltration membrane;

[0034] 2) Take 100mg (NH 4 ) 2 MoS 4and 138mg of cysteine were dissolved in 30ml of DMF, ultrasonicated for 15min, then transferred to an autoclave, and reacted at 200°C for 10h; Dialyzed with pure water for 48 hours to obtain amino group-containing MoS 2 Dispersion of nanodots.

[0035] 3) At room temperature, the mass concentration of piperazine was prepared to be 0.2%, and MoS containing amino groups 2 The dispersion concentration of nano-dots is the mixed dispersion liquid of 0.75g / L, and the trimesoyl chloride n-hexane solution with a mass concentration o...

Embodiment 2

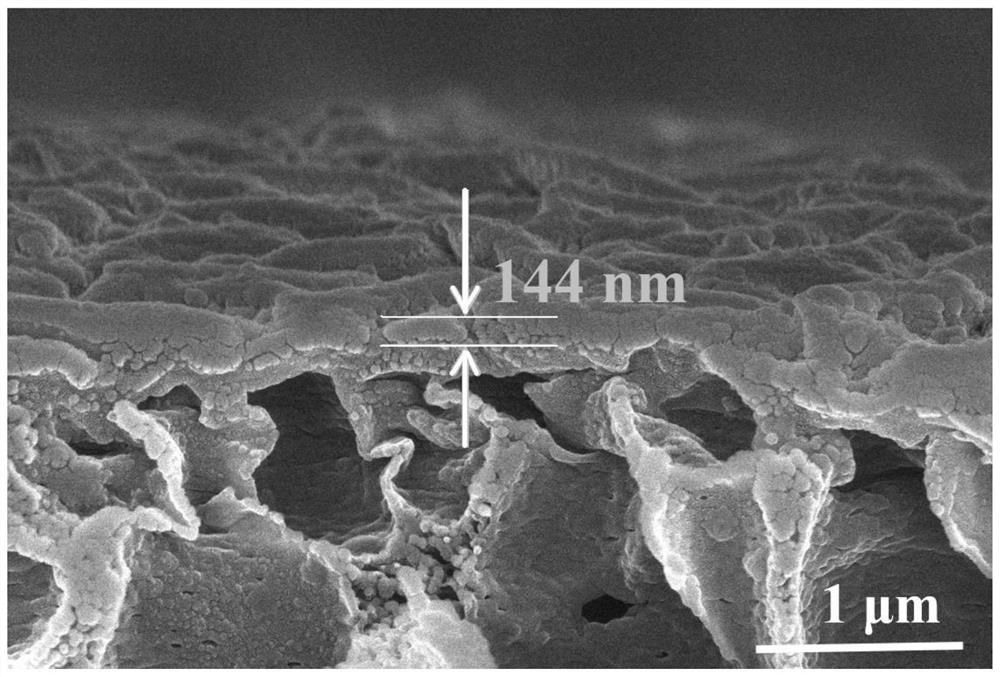

[0041] Preparation of MoS 2 Nanodot hybrid nanofiltration membrane, in the preparation process of this example, the specific steps are basically the same as in Example 1, the only difference is that in the mixed dispersion prepared in step 3), the amino group-containing MoS 2 The dispersion concentration of nanodots is 0.25 g / L, and MoS with a selective layer thickness of about 144 nm is finally prepared. 2 Nanofiltration membranes hybridized with nanodots.

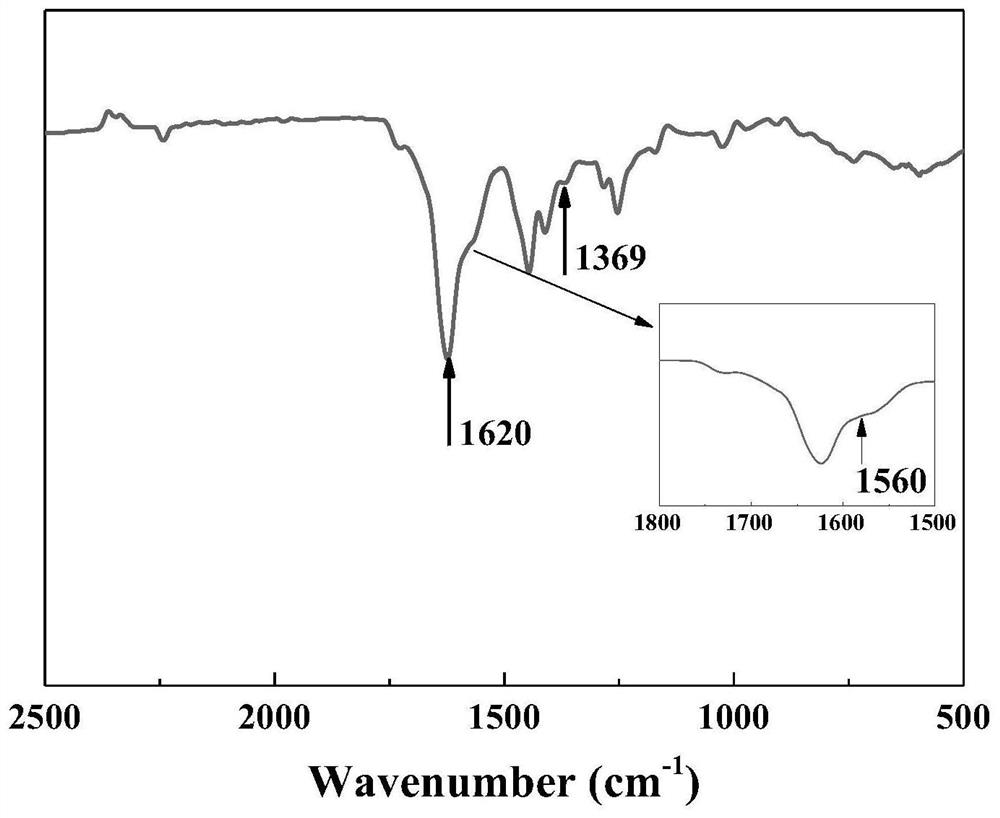

[0042] figure 2 For the surface infrared characterization figure of the hybrid nanofiltration membrane that embodiment 2 obtains, by figure 2 available at 1620cm -1 The absorption peak at belongs to the C=O stretching vibration of the amide band, located at 1369cm -1 The absorption peak at corresponds to the C-N stretching vibration of the amide band. This indicates the formation of a polyamide layer on the polyacrylonitrile ultrafiltration membrane. at 1560cm -1 The absorption peak at belongs to aminated MoS 2 ...

Embodiment 3

[0045] Preparation of MoS 2 Nanodot hybrid nanofiltration membrane, in the preparation process of this example, the specific steps are basically the same as in Example 1, the only difference is that in the mixed dispersion prepared in step 3), MoS 2 The dispersion concentration of nanodots is 1g / L, and MoS with a selective layer thickness of about 144nm is finally prepared. 2 Nanofiltration membranes hybridized with nanodots.

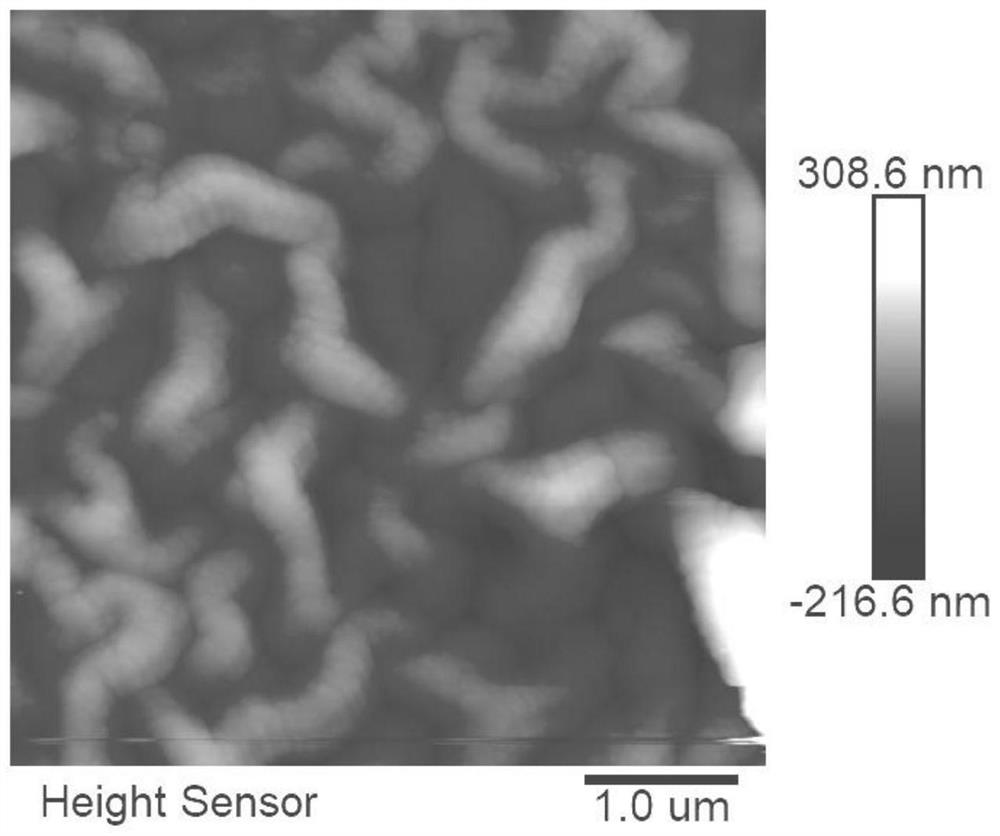

[0046] image 3 For the surface AFM figure of the hybrid nanofiltration membrane that embodiment 3 makes, by image 3 It can be seen that the surface of the prepared nanofiltration membrane has large folds and protrusions, which are interconnected to form a network, forming an obvious Turing structure, and the roughness is high, which is conducive to obtaining a large water flux. Since the main component of the film is still the polyamide layer formed by piperazine and trimesoyl chloride, it shows that the MoS in the present invention 2 Nanodot hybr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com