Benzene-free solvent type peelable pressure-sensitive adhesive and preparation method thereof

A pressure-sensitive adhesive and solvent-based technology, applied in the field of pressure-sensitive adhesives, can solve problems such as restricting the use of volatile organic compounds, increasing organic waste gas emissions, and health hazards, and achieves improved peelability, improved bonding performance, and volatile The effect of high speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

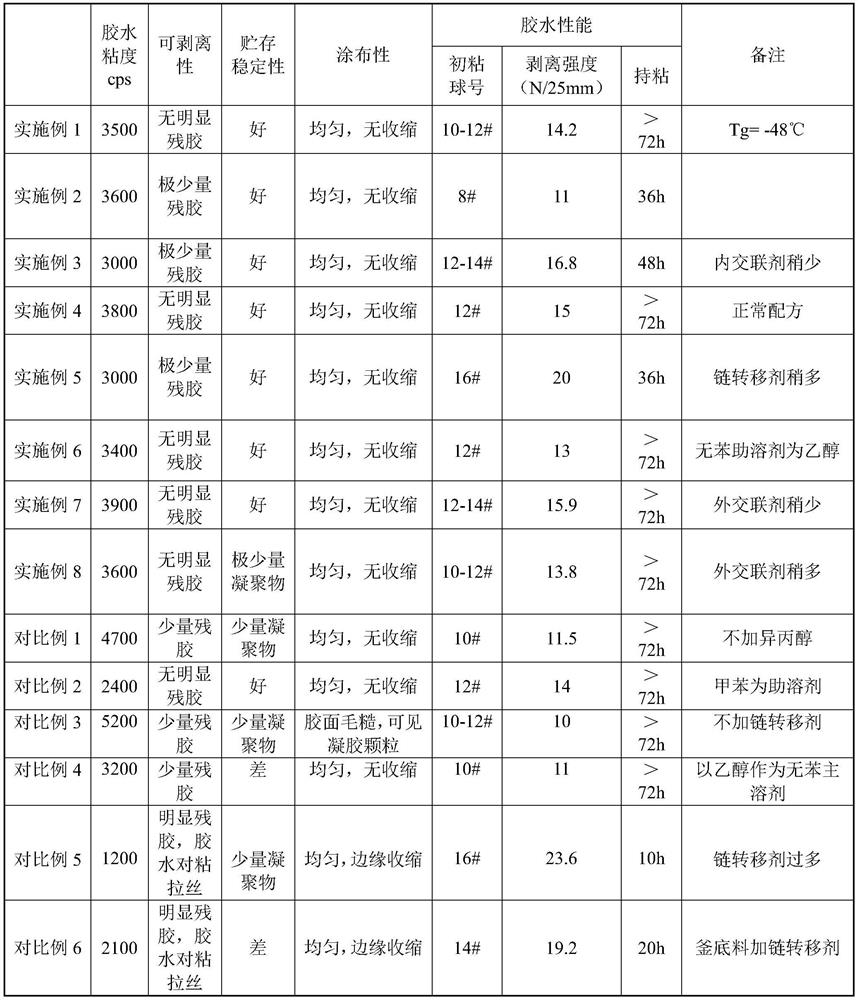

Examples

preparation example Construction

[0086] A second aspect of the invention provides a method for preparing a non-p-lyl solvent type peelable pressure sensitive, comprising the steps of:

[0087] 1) Preparation of the monomer mixture: It is weighing the hard monomer, an acrylate soft monomer, a functional monomer, an inner crosslinked monomer, and a monomer mixture is obtained, and the monomer mixture is mixed with 5% concentration of sodium hydroxide solution mixed, washing the monomer, remove the polymerization agent, spare;

[0088] 2) Preparation of the kettle: It is weighed with an initiator, a non-phenorbone solvent, and a non-p-free solvent, and the monomer mixture obtained by removing the polymerization agent from 15% by weight and 10% by weight. Part of the initiator, 20% by weight of a no-phenorbone solvent and all parts of the othlebrene-free solvent mix, dissolve, and mixed into a suction;

[0089] 3) Preparation of dripping liquid: It is known to mix the remaining part of the monomer mixture, the initia...

Embodiment 1

[0098] Example 1 provides a non-p-free solvent-type peelable pressure sensitive, according to a mass, the preparation of the pressure sensitive comprises 140 ester solvents, 7 parts of the alcohol solvent, 17 parts of hard cells, acrylic acid 70 ester soft monomers, 6 functional monomers, 0.15 inner crosslinking monomers, 0.05 parts of chain transfer agents, 0.8 initiationers, 1 diplomatic agent.

[0099] The ester solvent is ethyl acetate, and the CAS number is from 141 to 78-6, the alcohol solvent is isopropyl alcohol, and the CAS number is 67-63-0.

[0100] The hard monomer is methyl acrylate which is a mixture of ethyl acrylate, octyl acrylate, and acrylate, the functional monomer being acrylic acid and acrylic-2-hydroxypropyl. Mixture, the inner crosslinked monomer is a mixture of methacrylate and N-hydroxymethyl methacrylate, 17 parts of methacrylate, 4 parts of acrylate, and 13 acrylic acid n-butyl acrylate. Octal acrylate, 4 parts of acrylic, 2 parts of acrylic acid-2-hydr...

Embodiment 2

[0114] Example 2 provides a non-p-free solvent-type peelable pressure sensitive adhesive, and the preparation of the pressure-sensitive glue is 90 parts of ester solvent, 4 of the alcohol solvent, 12 parts of hard cells, acrylic acid. Ester soft monomer, 6 functional monomers, 0.2 parts of the internal crosslinked monomer, 0.05 parts of the chain transfer agent, 0.5 primary initiators, and the diplomatic agent.

[0115] The ester solvent is ethyl acetate, and the CAS number is from 141 to 78-6, the alcohol solvent is isopropyl alcohol, and the CAS number is 67-63-0.

[0116] The hard monomer is methyl acrylate which is a mixture of ethyl acrylate, octyl acrylate, and acrylate, the functional monomer being acrylic acid and acrylic-2-hydroxypropyl. Mixture, the inner crosslinked monomer is a mixture of methacrylate and N-hydroxymethyl methacrylate, 12 parts of methyl acrylate, 5 parts of ethyl acrylate, 15 parts of acrylic acid, abut ester acrylate. 65 parts, 4 servium acrylic, 2 pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com