A kind of preparation method of marine plant polysaccharide anti-adhesion material

A marine plant and anti-adhesion technology, which is applied in drug delivery, pharmaceutical formulation, surgery, etc., can solve the problems that sodium hyaluronate is easy to cause fever, polylactic acid degrades for a long time, and there are foreign objects in the surgical site, etc., so as to prevent adhesion and facilitate The effect of simple operation and preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

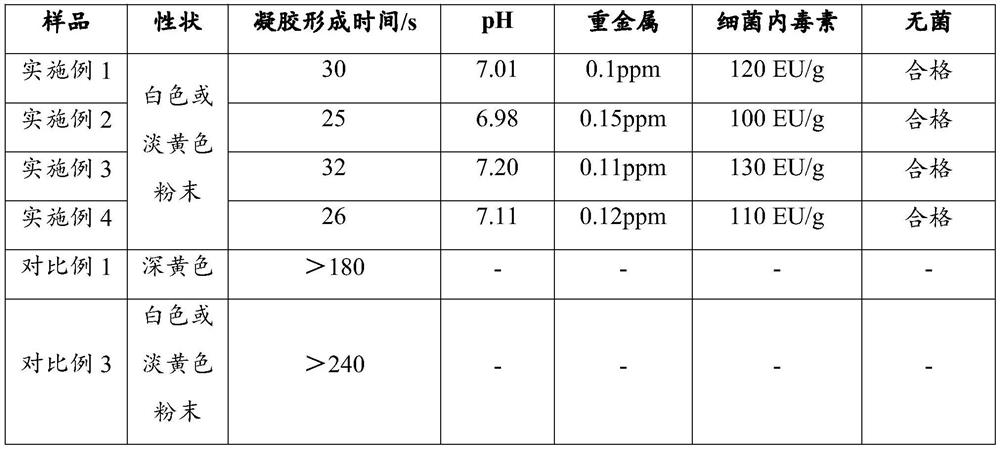

Embodiment 1

[0026] A preparation method of marine plant polysaccharide anti-adhesion material, the specific steps are as follows:

[0027] (1) Dissolve commercially available pharmaceutical excipient grade sodium alginate with a molecular weight of 10,000 in a 0.4% w / w sodium chloride aqueous solution to make a solution with a concentration of 2% w / w; add activated carbon, activated carbon and alginic acid The mass ratio of sodium is 3:1, stirring at 30°C for 4 hours, centrifuging the mixture at 9000 rpm for 30 minutes, and taking the supernatant to obtain a sodium alginate solution;

[0028] (2) Under stirring at 50°C and 500rpm, add 1%w / w calcium chloride to the sodium alginate solution obtained in step (1) through a 26G injection needle to form gel microspheres, continue stirring for 2h, and centrifuge at 9000rpm 30min, take the precipitate and wash the gel microspheres with distilled water;

[0029] (3) after the gel microspheres cleaned in step (2) are stirred and soaked in a lactic...

Embodiment 2

[0034] A preparation method of marine plant polysaccharide anti-adhesion material, the specific steps are as follows:

[0035] (1) Dissolve commercially available pharmaceutical excipient grade potassium alginate with a molecular weight of 30,000 in a 0.6% w / w sodium nitrate aqueous solution to make a solution with a concentration of 2% w / w; add activated carbon, activated carbon and potassium alginate The mass ratio was 3:1, stirred at 40°C for 3h, centrifuged the mixture at 10,000rpm for 20min, and took the supernatant to obtain potassium alginate solution;

[0036] (2) Under stirring at 50°C and 1000rpm, add 5% w / w calcium gluconate to the potassium alginate solution obtained in step (1) through a 20G injection needle to form gel microspheres, and continue stirring for 1.5h at 10,000rpm. Centrifuge for 20min, take the precipitate and wash the gel microspheres with distilled water;

[0037] (3) after the gel microspheres cleaned in step (2) are stirred and soaked in a lacti...

Embodiment 3

[0042] A preparation method of marine plant polysaccharide anti-adhesion material, the specific steps are as follows:

[0043] (1) Dissolve oxidized sodium alginate with a molecular weight of 100,000 in a 0.9% w / w sodium lactate aqueous solution to make a solution with a concentration of 2% w / w; add activated carbon, and the mass ratio of activated carbon to oxidized sodium alginate is 3 : 1. Stir at 50°C for 0.5h, centrifuge the mixture at 12000rpm for 15min, and take the supernatant to obtain an oxidized sodium alginate solution;

[0044] (2) Under stirring at 30°C and 1500rpm, add 10% w / w calcium nitrate to the oxidized sodium alginate solution obtained in step (1) through a 24G injection needle to form gel microspheres, continue stirring for 1h, and centrifuge at 12,000rpm 15min, take the precipitate and wash the gel microspheres with distilled water;

[0045] (3) after the gel microspheres cleaned in step (2) are stirred and soaked in a lactic acid solution of pH=4 for 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com