Method and system for producing high-silicon compound fertilizer by activating coal gangue

A technology of coal gangue and compound fertilizer, applied in the directions of potash fertilizer, magnesium fertilizer, organic fertilizer, etc., can solve the problem of difficult large-scale utilization of coal gangue, and achieve the effects of enhancing energy flow density, reducing microwave power, and expanding processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

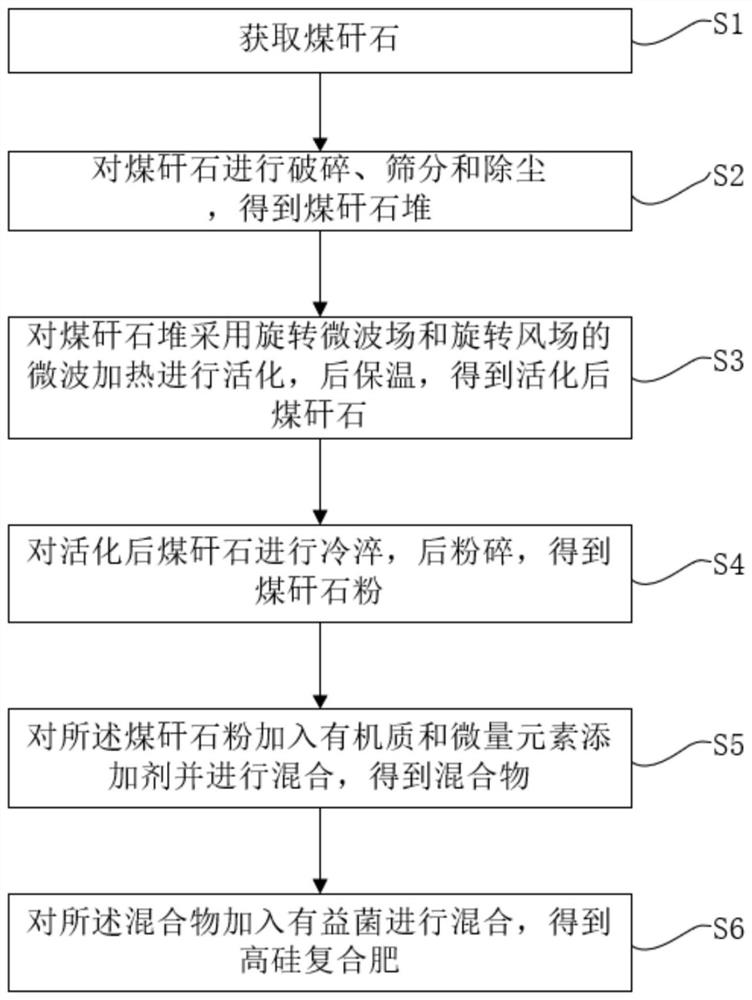

[0095] A method for activating coal gangue to produce high-silicon compound fertilizer, the method comprising:

[0096] S1. Obtain coal gangue;

[0097] S2. Crushing, screening and dedusting the coal gangue to obtain a coal gangue pile;

[0098] S3. The coal gangue pile is activated by microwave heating in a rotating microwave field and a rotating wind field, and then kept warm to obtain activated gangue;

[0099] S4. The activated coal gangue is quenched and crushed to obtain coal gangue powder;

[0100] S5. Adding organic matter and trace element additives to the gangue powder and mixing to obtain a mixture;

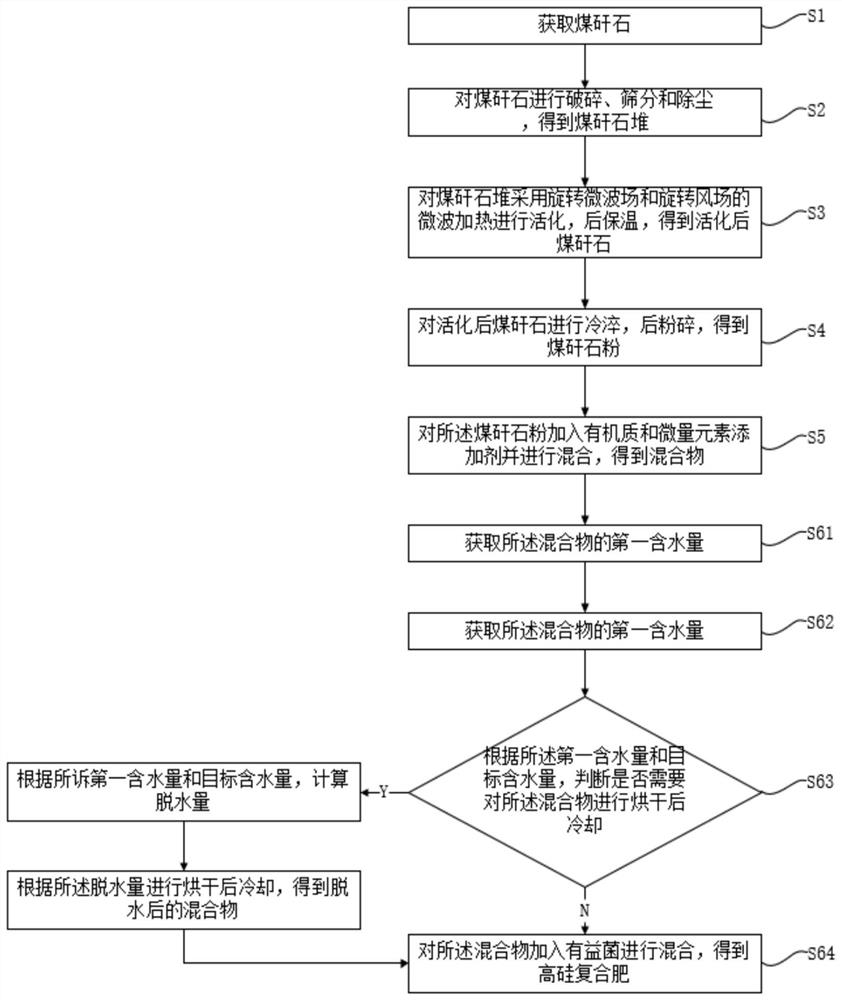

[0101] S61. Obtain the first water content of the mixture;

[0102] S62 obtaining the target water content of the mixture;

[0103] S63 According to the first water content and the target water content, it is judged whether the mixture needs to be air-dried and then cooled;

[0104] If yes, calculate the dehydration amount according to the first water content and ...

Embodiment 2

[0126] Compared with embodiment 2 and embodiment 1, the difference between embodiment 2 and embodiment 1 is:

[0127] The end temperature of microwave heating is 700°C, and the time is 40min;

[0128] The time of heat preservation is 40min.

[0129] The particle size of the coal gangue pile is 5mm to 25mm.

[0130] Organic matter includes chicken manure and peat;

[0131] Trace elements include trace element additives containing at least one of phosphorus, potassium, calcium, magnesium, zinc, selenium, copper, molybdenum, chromium, cobalt, and iron; beneficial bacteria include Bacillus subtilis, Bacillus megaterium, Bacillus licheniformis and thuringiensis At least one type of bacillus, in which trace elements and beneficial bacteria are added according to the lack of soil testing to ensure the quality and effect of the fertilizer.

[0132] The activation box is set at 35° to the horizontal plane.

[0133] The distribution porosity of the air distribution holes 331 on the ...

Embodiment 3

[0136] Embodiment 3 is compared with embodiment 1, and the difference between embodiment 3 and embodiment 1 is:

[0137] The end temperature of microwave heating is 850°C, and the time is 60min;

[0138] The time of heat preservation is 50min.

[0139] The activation box is set at 85° to the horizontal plane.

[0140] The particle size of the coal gangue pile is 5mm to 25mm.

[0141] Organic matter includes chicken manure and peat;

[0142] Trace elements include trace element additives containing at least one of phosphorus, potassium, calcium, magnesium, zinc, selenium, copper, molybdenum, chromium, cobalt, and iron; beneficial bacteria include Bacillus subtilis, Bacillus megaterium, Bacillus licheniformis and thuringiensis At least one type of bacillus, in which trace elements and beneficial bacteria are added according to the lack of soil testing to ensure the quality and effect of the fertilizer.

[0143] The distribution porosity of the air distribution holes 331 on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com