Preparation and application of bimetal organic framework composite nitrogen-doped graphene catalytic material

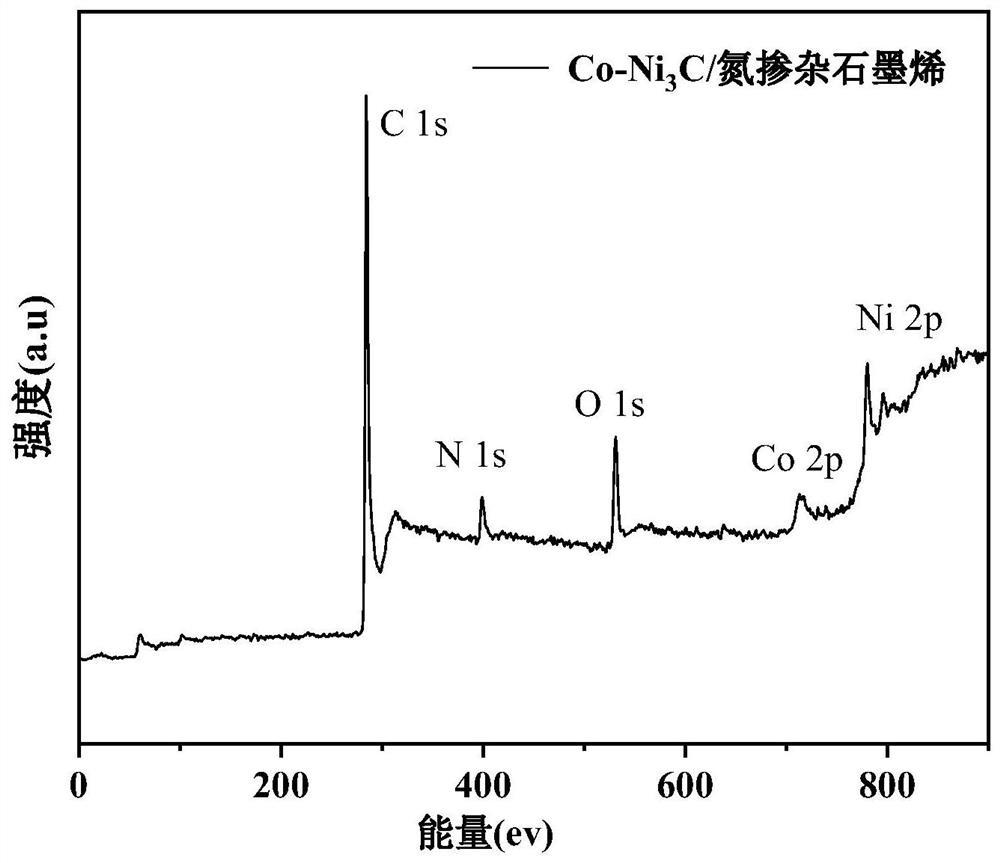

A nitrogen-doped graphene, catalytic material technology, applied in fuel cells, electrochemical generators, electrical components and other directions, can solve the problems of poor nanoparticle dispersion and insignificant catalytic performance, and achieve good alcohol oxidation activity and product availability. control, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A kind of preparation of bimetallic organic framework composite nitrogen-doped graphene catalytic material, comprises the following steps:

[0032] (1) 0.2488g nickel acetate tetrahydrate, 0.7276g cobalt nitrate hexahydrate and 50mg graphene were successively added to the constantly stirring 50mL methanol solution and dispersed completely to obtain solution A;

[0033] (2) Add 1.6423g of dimethylimidazole to solution A at a rate of 0.2g per minute, stirring while adding, until the dissolution is complete, continue stirring until a uniformly mixed mixed solution B is obtained;

[0034] (3) Transfer the mixed solution B to a refrigerator with a temperature of 0° C. to induce crystallization and precipitation for 20 h, then filter, wash twice with distilled water and ethanol, and dry in vacuum at 50° C. to obtain a solid mixture C;

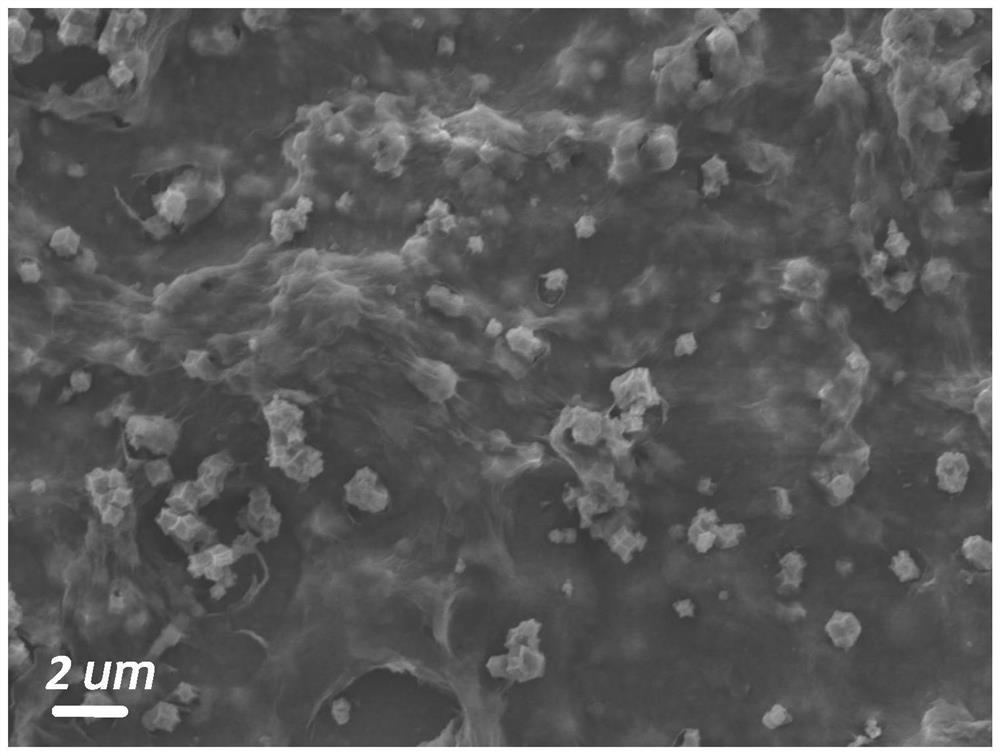

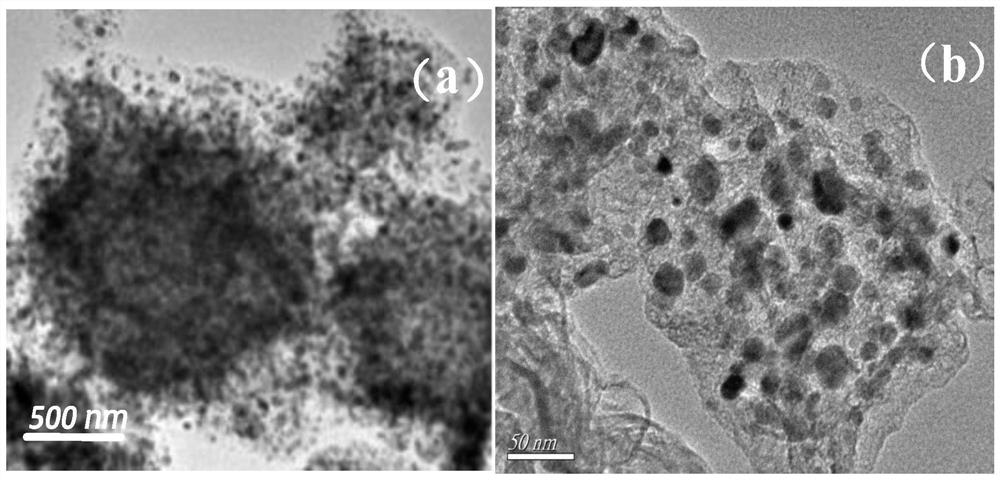

[0035] (4) Grind the solid mixture C evenly and place it in a tube furnace for calcination. The heating process is programmed heating. The fi...

Embodiment 2

[0038] A kind of preparation of bimetallic organic framework composite nitrogen-doped graphene catalytic material, comprises the following steps:

[0039] (1) 0.4976g nickel acetate tetrahydrate, 0.8731g cobalt nitrate hexahydrate and 70mg graphene were successively added to the constantly stirring 50mL methanol solution and dispersed completely to obtain solution A;

[0040] (2) Add 2.4630 g of dimethylimidazole to solution A at a rate of 0.2 g per minute, stirring while adding, until the dissolution is complete, continue stirring until a uniformly mixed solution B is obtained;

[0041] (3) Transfer the mixed solution B to a refrigerator with a temperature of 2° C. to induce crystallization and precipitation for 22 hours, then filter, wash twice with distilled water and ethanol, and dry under vacuum at 60° C. to obtain a solid mixture C;

[0042](4) Grind product C evenly and place it in a tube furnace for calcination. The heating process is programmed temperature rise. The f...

Embodiment 3

[0045] A kind of preparation of bimetallic organic framework composite nitrogen-doped graphene catalytic material, comprises the following steps:

[0046] (1) 0.6221g of nickel acetate tetrahydrate, 1.1641g of cobalt nitrate hexahydrate and 90mg of graphene were successively added to the constantly stirring 50mL methanol solution and dispersed completely to obtain solution A;

[0047] (2) Add 3.2840 g of dimethylimidazole to solution A at a rate of 0.2 g per minute, stirring while adding, until the dissolution is complete, continue stirring until a uniformly mixed mixed solution B is obtained;

[0048] (3) Transfer the mixed solution B to a refrigerator with a temperature of 3° C. to induce crystallization and precipitation for 24 hours, then filter, wash twice with distilled water and ethanol, and dry in vacuum at 70° C. to obtain a solid mixture C;

[0049] (4) Grind the product C evenly and place it in a tube furnace for calcination. The heating process is programmed temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com