Preparation method of PtCo intermetallic compound catalyst, and fuel cell

An intermetallic compound and catalyst technology, which is applied in battery electrodes, circuits, electrical components, etc., can solve the problems of large particle size, low degree of ordering, and low metal loading of PtCo-IMC, and achieves the promotion of efficient formation and particle size. The effect of good diameter uniformity and high discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

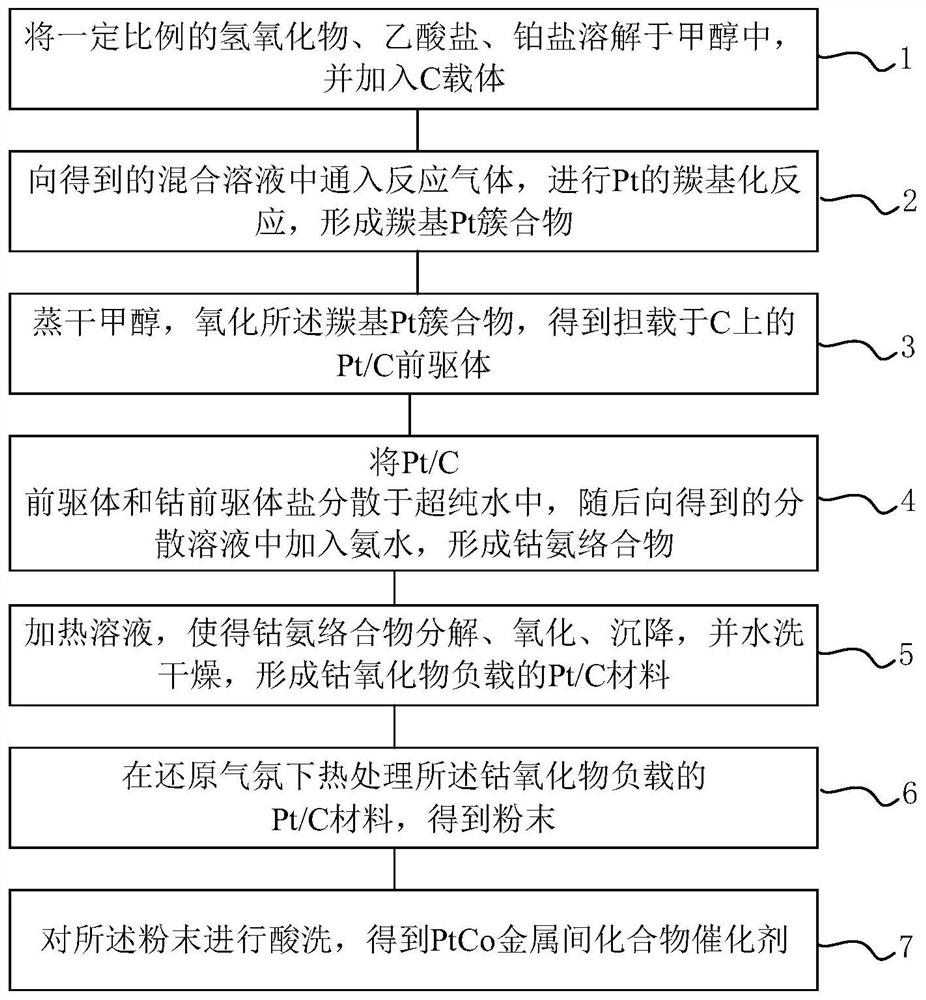

[0033] In this embodiment, the preparation method of the PtCo intermetallic catalyst comprises the following steps:

[0034] Step 1: Dissolve a certain proportion of hydroxide, acetate and platinum salt in methanol, and add C carrier.

[0035] The methanol solution is deoxygenated in advance.

[0036] The platinum salt includes: at least one of chloroplatinic acid, sodium chloroplatinate, platinum acetylacetonate, potassium chloroplatinite and tetraaminodinitroplatinum; the hydroxide includes: sodium hydroxide, hydrogen At least one of potassium oxide, lithium hydroxide and ammonia water; the acetate includes at least one of sodium acetate, potassium acetate and cobalt acetate.

[0037] In the embodiment of the present invention, the molar ratio of platinum salt, hydroxide and acetate salt is 1:(2-4):(4-8).

[0038] The C carrier may be carbon powder, and the mass ratio of carbon powder to Pt may be (3-6):(4-7), for example, 6:4, 4:6 or 3:7. Specifically, the type of the ca...

Embodiment 1

[0067] 1) Weigh 82 mg of NaOH particles and 336.4 mg of sodium acetate powder in a round-bottomed flask, add 20 mL of methanol solution, and magnetically stir for 1 hour to fully dissolve the two until the solution is clear; then weigh 263.2 mg of chloroplatinic acid Dissolved in 10 mL of methanol solution, ultrasonically dispersed and dissolved to obtain a yellow solution; pour the above chloroplatinic acid solution into a round-bottomed flask and mix well; then, continue to feed N 2 Drive away the oxygen in the solution to achieve the purpose of deoxygenation.

[0068] 2) One mouth of the round-bottomed flask was connected to CO gas, the gas flow was adjusted to 50 sccm, and the gas was continuously fed, and the flask was placed in a water bath, and the temperature was set at 55 ° C, and the reaction was carried out for 12 hours to carry out carbonylation treatment. During the reaction, the color of the solution changed from yellow to dark green.

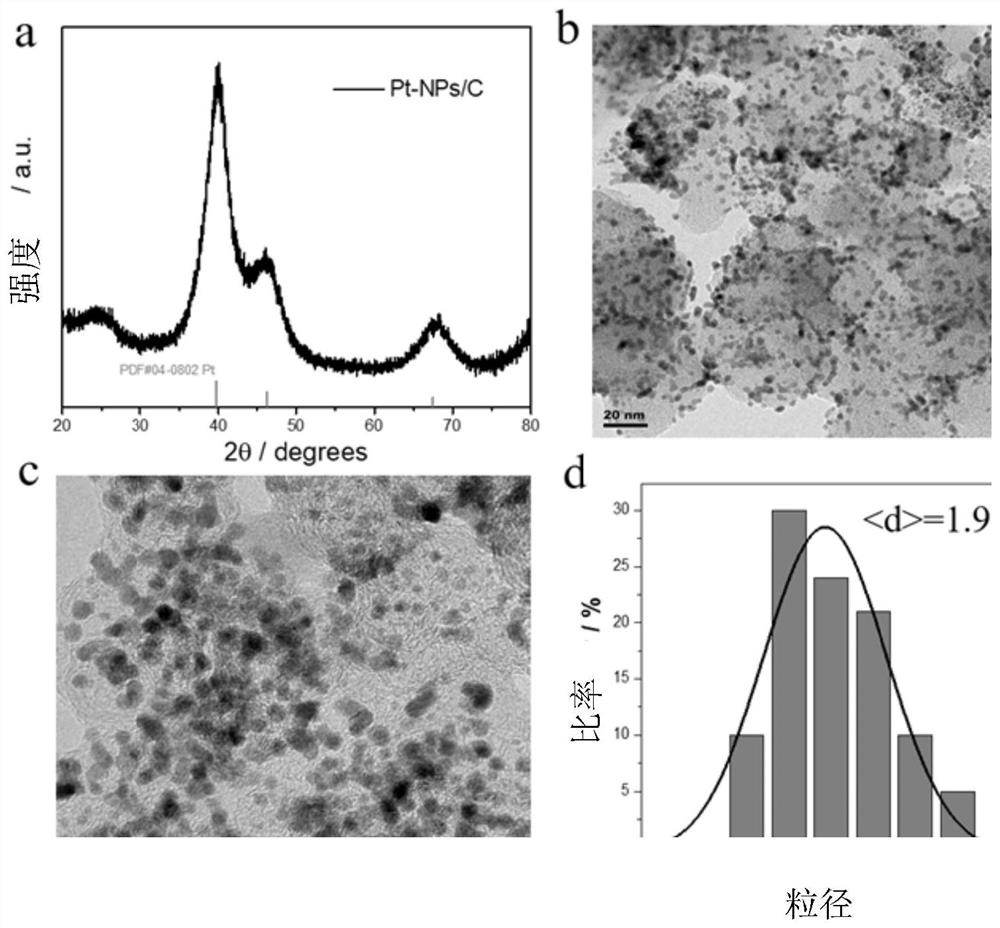

[0069] 3) Weigh 150 mg of...

Embodiment 2

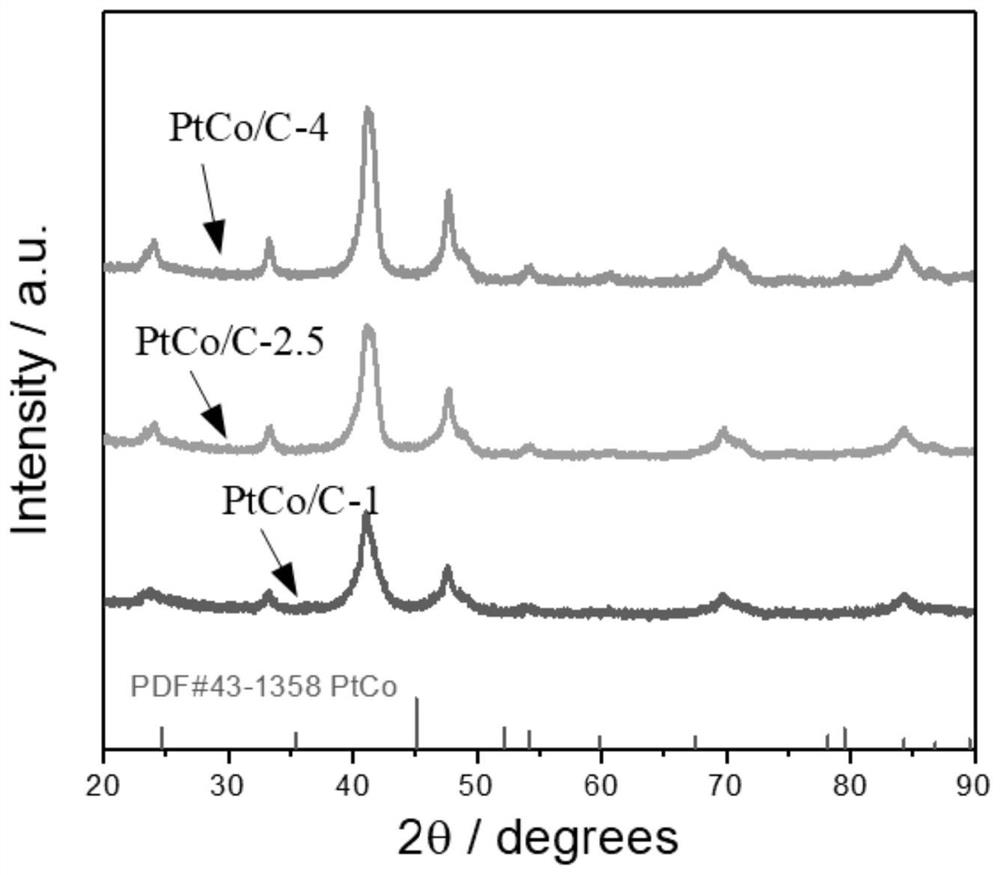

[0078] According to the first 8 steps in the above-mentioned embodiment 1, in particular, in step 8), the heat treatment process is set as follows: 7°C / min is raised from room temperature to 300°C, and kept for 2 hours; The temperature was raised to 700°C for 1 min, and the two samples were kept for 1 hour and 4 hours respectively; then the temperature was naturally lowered, the lid was opened, and the heat-treated samples were taken out; then PtCo-IMC-1 and PtCo-IMC-4 were obtained according to step 9 in Example 1. Catalyst, where "1" and "4" refer to the corresponding products that are kept for 1 hour and 4 hours, respectively. The crystal structure is as follows figure 2 shown. ,

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com