Gradient density scaffold material as well as preparation method and application thereof

A technology of gradient density and scaffolding materials, applied in the field of additive manufacturing, can solve problems such as uneven stress distribution, difficulty in meeting comprehensive performance requirements, and difficulty in controlling microstructural interconnectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

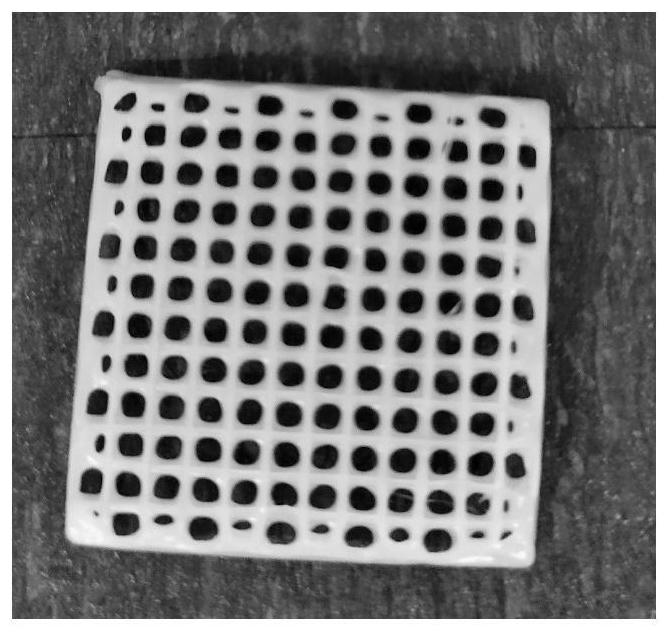

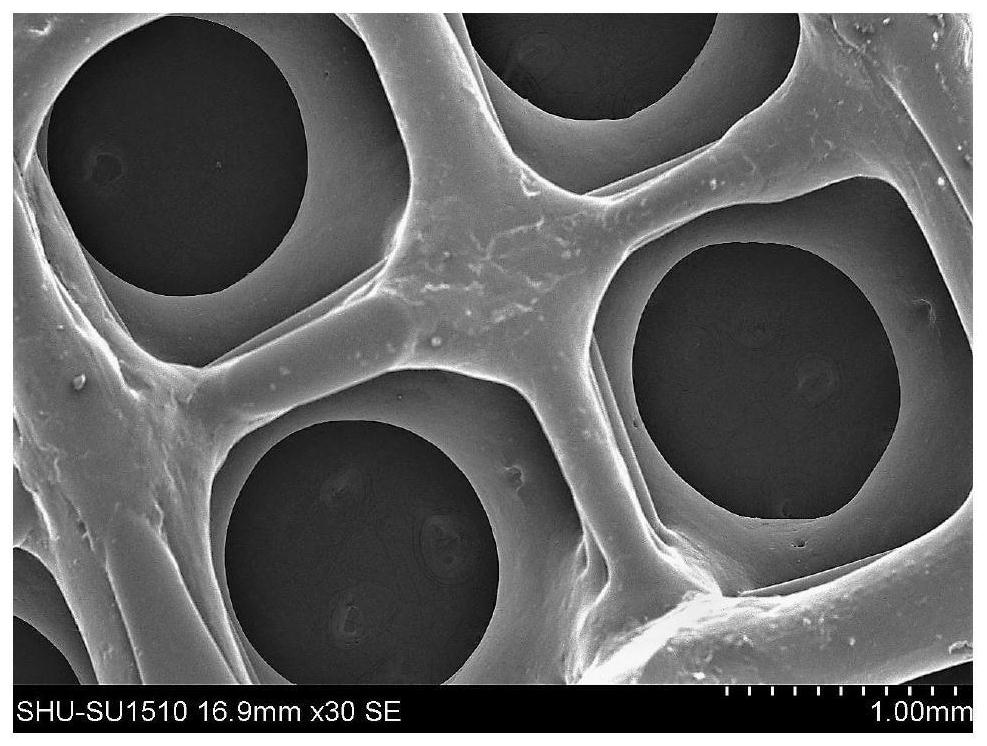

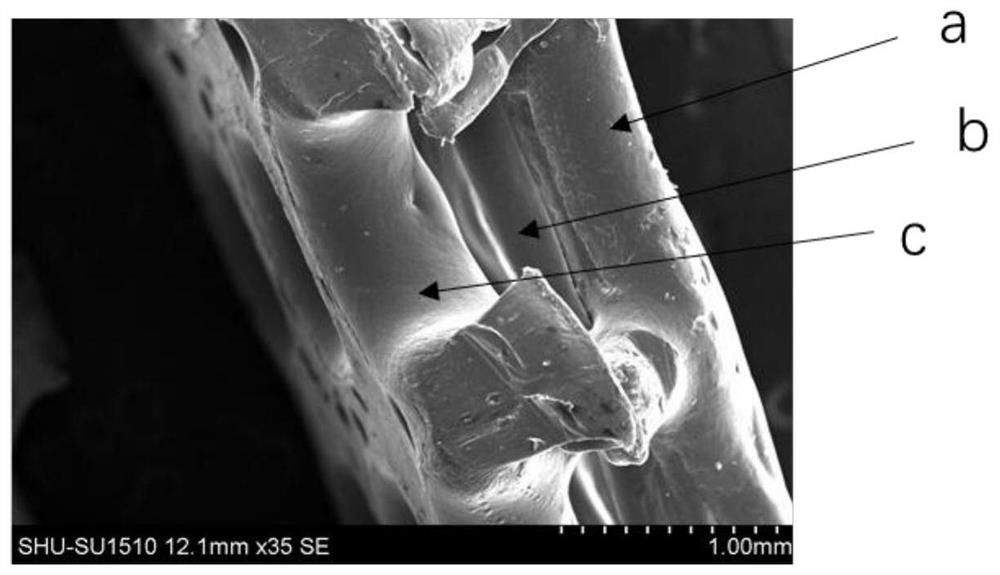

[0036] The invention provides a method for preparing a gradient density scaffold material, comprising the following steps:

[0037] Mix organic matter, inorganic matter and organic solvent to obtain liquid A; the organic matter includes one or more of polycaprolactone, polyvinyl alcohol, polylactic acid, gelatin, sodium alginate, collagen and fibrin; the Inorganic substances include one or more of hydroxyapatite, calcium phosphate, calcium tripolyphosphate, bioactive glass and calcium silicate;

[0038] Provide chitosan-acetic acid aqueous solution as B liquid;

[0039] dynamically mixing the liquid A and the liquid B, and performing additive printing on the obtained dynamic mixed liquid to obtain the gradient density scaffold;

[0040] The dynamic mixing is: extruding and mixing liquid A and liquid B according to different extrusion rates to obtain a dynamic mixed liquid.

[0041] In the present invention, unless otherwise specified, each component in the preparation method...

Embodiment 1

[0069] Mix and dissolve 8 g of polycaprolactone and 10 mL of dichloromethane in a closed container for 12 hours to obtain a polycaprolactone solution; mix the obtained polycaprolactone solution with 0.8 g of hydroxyapatite to obtain liquid A;

[0070] Mix 1 g of chitosan with 10 mL of acetic acid aqueous solution (the volume of acetic acid and deionized water is 1:9) to obtain liquid B;

[0071] Inject liquid A into the 3D bioprinting syringe of liquid A, inject liquid B into the 3D bioprinting syringe of liquid B, install the syringe and fix the piston, connect the air tanks through different air pressure controllers, and adjust the air pressure to 0.2MPa for ventilation Squeeze to remove the air in the end of the 3D bioprinting syringe, and let the air bubbles in the 3D bioprinting syringe settle;

[0072] Connect the needles of liquid A 3D bioprinting syringe and liquid B 3D bioprinting syringe to the two inlets of the U-shaped three-way valve respectively, the outlet of th...

Embodiment 2

[0081] Mix and dissolve 9 g of polycaprolactone and 10 mL of dichloromethane in a closed container for 12 hours to obtain a polycaprolactone solution; mix the obtained polycaprolactone solution with 1.5 g of hydroxyapatite to obtain liquid A;

[0082] Mix 0.5g chitosan with 10mL acetic acid aqueous solution (the volume of acetic acid and deionized water is 1:9) to obtain liquid B;

[0083] Inject liquid A into the 3D bioprinting syringe of liquid A, and inject liquid B into the 3D bioprinting syringe of liquid B. After installing the syringe and fixing the piston, connect the air tanks through different air pressure controllers, and adjust the air pressure to 0.3MPa for ventilation. Squeeze to remove the air in the end of the 3D bioprinting syringe, and let the air bubbles in the 3D bioprinting syringe settle;

[0084] Connect the needles of liquid A 3D bioprinting syringe and liquid B 3D bioprinting syringe to the two inlets of the U-shaped three-way valve respectively, the out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Overall width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com