Single-crystal indium micron sheet and synthetic method and application thereof

A synthesis method and technology of micro-sheets, applied in the field of preparation and application of micro-nano materials, can solve problems such as difficulty in obtaining large-area single-crystal metal micro-sheets, and achieve high yield, strong adhesion, and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] A method for synthesizing single-crystal indium micro-sheets is as follows: using polyhydric alcohol as a solvent, citrate as a surfactant, and borohydride salt as a reducing agent, and adopting a wet chemical method to synthesize indium micro-sheets. The specific experimental steps are as follows. First, take an appropriate amount of polyol and pour it into a three-necked flask, and blow nitrogen into it. Next, pour the citrate and the indium salt into the three-necked flask, heat it to 70-150° C., and keep it warm for a while. Then weigh an appropriate amount of borohydride salt and make it into a solution with an appropriate amount of deionized water. The borohydride salt solution was quickly poured into the three-necked flask, and after a period of reaction, rapid cooling was performed. Finally, the cooled sample was centrifuged, washed with alcohol and centrifuged several times, and the centrifuged sample was dispersed in ethanol for storage.

[0032] First of a...

Embodiment 1

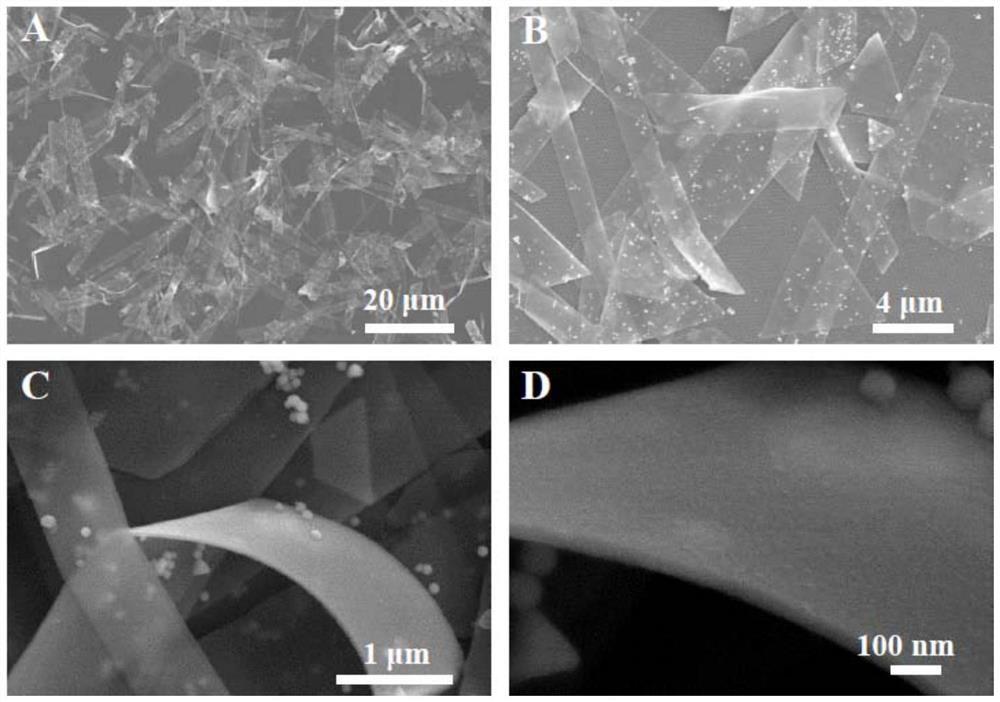

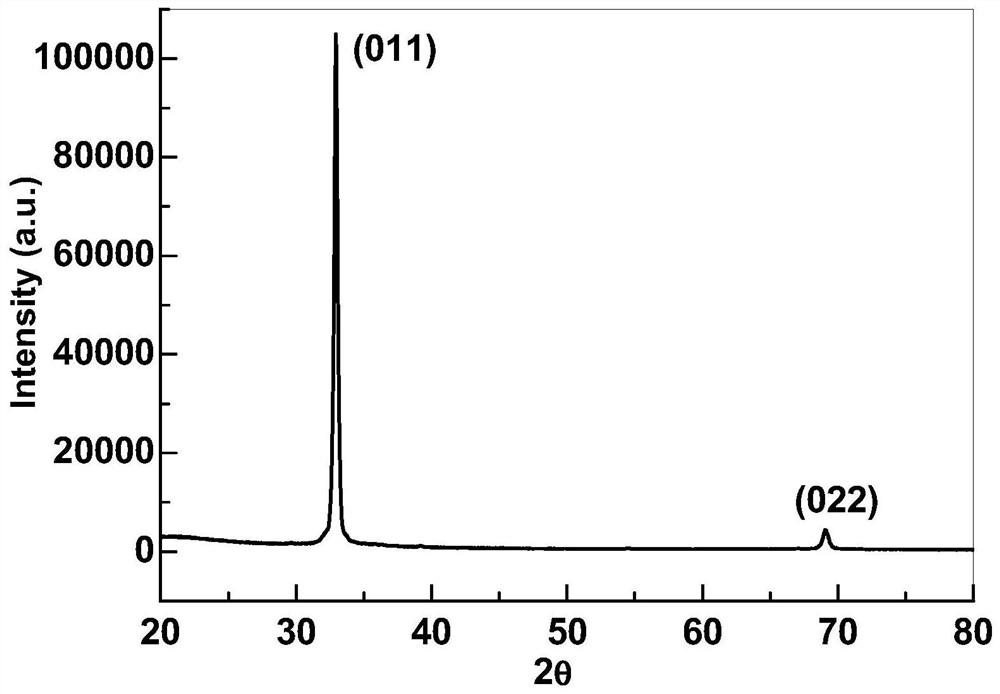

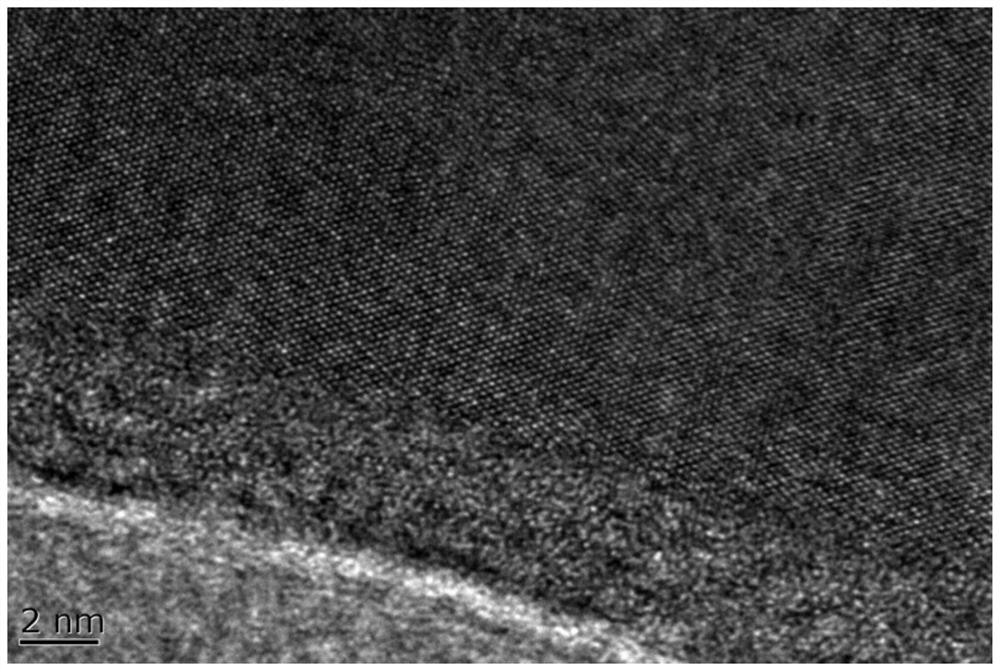

[0035] First, 80 mL of diethylene glycol was added to the three-necked flask, and nitrogen gas was introduced and stirred, and then 2×10 -3 mol indium chloride tetrahydrate and 1.52×10 -3 mol of disodium citrate was put into a three-necked flask, and then heated to 100°C in an oil bath while stirring, and then kept warm for 30min, then added with 4×10 -3mol of sodium borohydride in 1.6mL aqueous solution, the color of the solution rapidly changed from colorless to gray. After reacting for 5 minutes, move to room temperature water for rapid cooling. Indium microflakes with a thickness of 35-80 nm, a length of 5-50 μm and a width of 0.5-5 μm are finally obtained. Among them, after cooling in water for 1.5 minutes, the appearance of shiny substances in the solution can be observed with the naked eye. Finally, after cooling for 1 hour, it is centrifuged and washed with alcohol and then stored in ethanol. After being dispersed in ethanol and precipitated for 12 hours, it is found...

Embodiment 2

[0043] First, 80 mL of diethylene glycol was added to the three-necked flask, and nitrogen gas was introduced and stirred, and then 2×10 -3 mol indium chloride tetrahydrate and 1.52×10 -3 mol disodium citrate was put into a three-necked flask, then stirred and heated to 100°C, and then kept warm for 30min, adding 4×10 -3 mol of sodium borohydride in 1.6mL aqueous solution, reacted for 5min, then moved to 0°C ice-water mixture for rapid cooling. Indium microflakes with a thickness of 35-80 nm, a length of 5-50 μm and a width of 0.5-5 μm are finally obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com