Preparation method of organic-inorganic composite full-nutrient microbial fertilizer

A technology of microbial fertilizer and inorganic compounding, applied in organic fertilizers, inorganic fertilizers, urea compound fertilizers, etc., can solve the problems of affecting fertilizer quality and decreasing fertilizer efficiency, and achieve the effects of improving crop quality, accelerating the decomposition of organic matter, and uniformly supplying fertilizers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

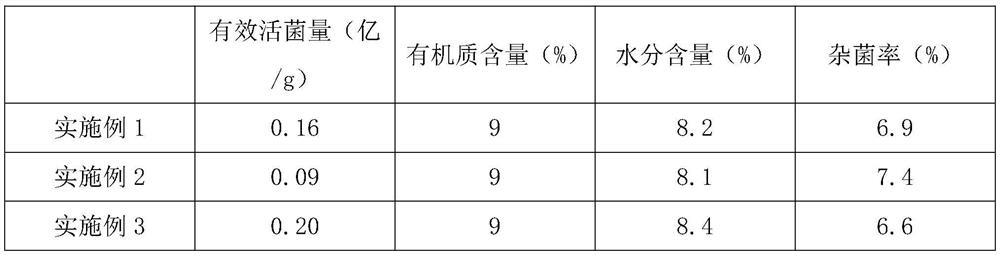

Examples

Embodiment 1

[0035] An organic-inorganic compound full-nutrient microbial fertilizer, the preparation method of which comprises the following steps:

[0036] S1. Preparation of organic fertilizer granules

[0037]Premix sheep manure or cow manure with broken straw at a mass ratio of 4:1, add 1wt.% EB decomposing agent, stir and add water to adjust the humidity of the mixed material to 60%, and then carry out biological fermentation. After the fermentation is completed, press the product Add 1-2% of calcium sulfate, magnesium sulfate, zinc sulfate monohydrate and / or manganese sulfate monohydrate to adjust the content of calcium, magnesium, zinc and manganese elements by dry weight. Granulating to make organic fertilizer granules;

[0038] S2. Functional bacteria culture load

[0039] Weigh the organic fertilizer particles and crush them, add porous carbon material and polyaniline gel, the mixing ratio of the organic fertilizer particles and the porous carbon material, polyaniline gel is 2...

Embodiment 2

[0048] An organic-inorganic composite full-nutrient microbial fertilizer, the preparation method of which is the same as in Example 1, except that the porous carbon material is replaced by an equivalent amount of commercial activated carbon.

Embodiment 3

[0050] An organic-inorganic compound full-nutrition microbial fertilizer, its preparation method is the same as that of Example 1, the difference is that: the porous calcium carbonate of 7wt.% is also included in the described culture substrate, and the preparation method of the porous calcium carbonate comprises the following steps:

[0051] Weigh the soluble starch and dissolve it in deionized water according to the ratio of solid to liquid 0.5g / 100mL, stir and heat up to 70-80°C and keep it warm for 36min until the dissolution is complete. After natural cooling to 50°C, add the final concentration of 1.8 Calcium acetate of g / 100mL, after dissolving completely, add an equal volume of 0.96g / 100mL ammonium carbonate solution, stir and react for 10h, separate the precipitate, wash with deionized water, and vacuum dry to obtain the porous calcium carbonate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com