Resin plugging agent and preparation method thereof

A technology of plugging agent and main agent, which is applied in the field of resin plugging agent and its preparation, can solve the problems of strong alkalinity of raw materials, not easy to degrade, and low success rate of high pressure, and achieve simple preparation method, high adhesion strength, The effect of high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] This example provides the preparation and plugging effect of a resin-based plugging agent.

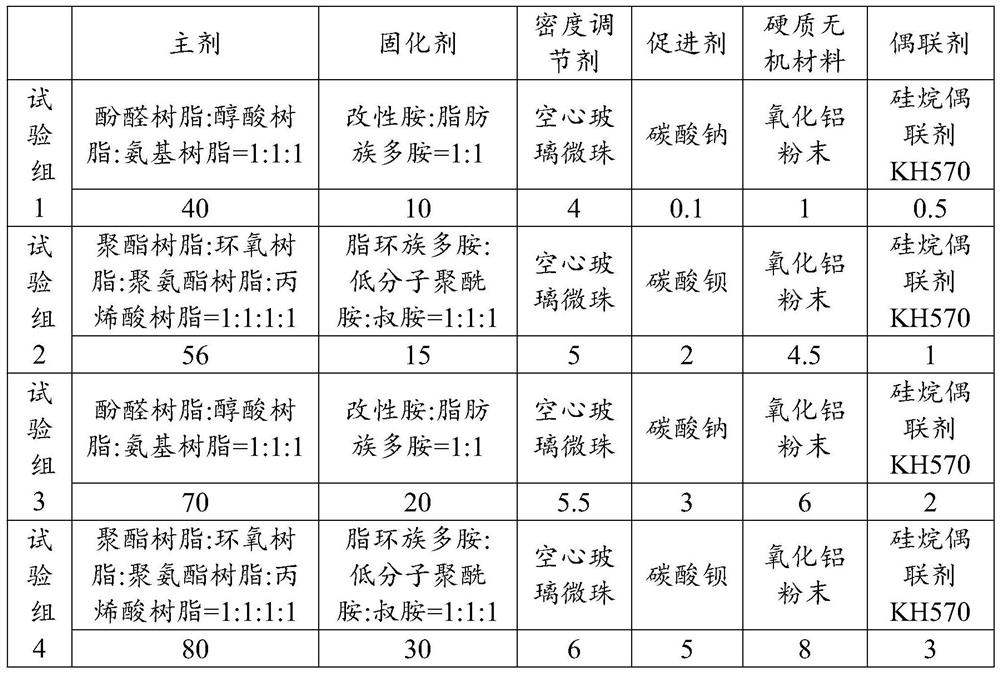

[0024] Add the main ingredient and water into the reaction kettle according to the mass ratio of 1:2, and then heat to 150-200°C and stir thoroughly until there are no lumps; add a density regulator to the obtained pasty substance, and stir it Add silane coupling agent KH570 and alumina powder (180-200 mesh) in sequence; after stirring and reacting for 30-60 minutes, add curing agent and 30% sodium carbonate solution or 30% barium carbonate solution, and stir at 60-100°C for 10 The blocking agent was obtained after ~30 min. The resin-based plugging agent described in this implementation is composed of the raw materials described in Table 1 in parts by mass.

[0025] Table 1. Composition and parts by mass of resin plugging agents

[0026]

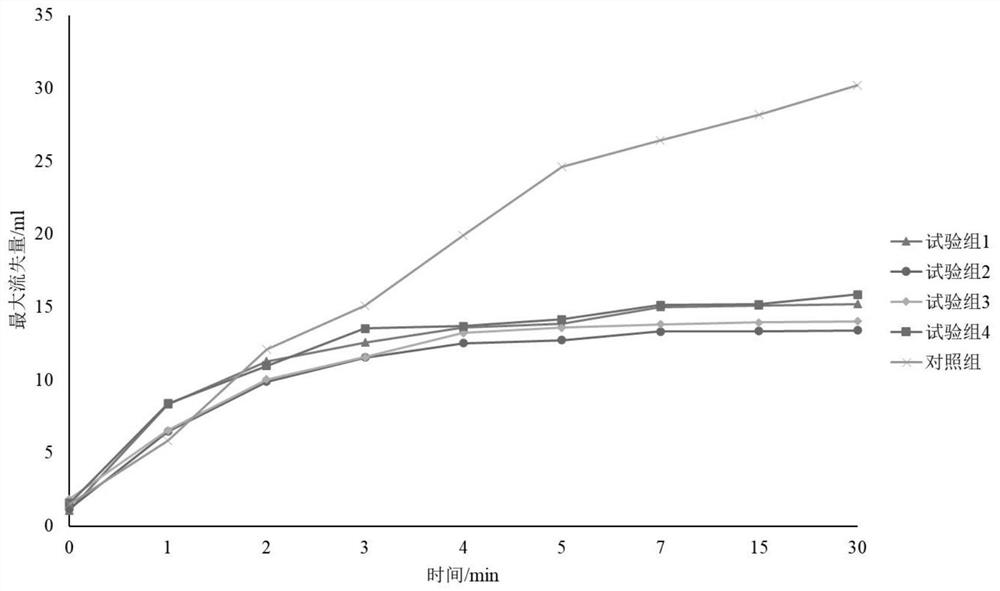

[0027] Prepare 4% high-quality bentonite base slurry, add 3% of the plugging agent after pre-hydration for 24 hours, and fully stir, agi...

Embodiment 2

[0030] This embodiment provides the practical application effect of a resin-based plugging agent.

[0031] The actual composition of the resin plugging agent used in this example is the same as that of the test group 3 in Example 1. Squeeze 4 to 15m into the target section of the oil well 3 After 0.5 to 3 hours under formation conditions, a rigid solidified body with micro-swelling, good cementation, and impact resistance is formed to achieve high-strength plugging of the target well section. During the on-site construction process of the plugging agent of the present invention, the highest pressure after plugging is 70MPa, the pressure test is 30min, the pressure drop is less than 0.5MPa, the pressure test is qualified, and there is no leakage in the subsequent fracturing process, which is successfully completed Subsequent fracturing operations.

[0032] The specific construction cases are as follows:

[0033] (1) The pressure test of well A-1 failed before fracturing. Aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com