Catalyst for catalytic combustion of organic volatile waste gas and preparation method thereof

A catalytic combustion and catalyst technology, applied in the field of catalysis, can solve the problems of poor thermal stability, large grain size of high-entropy oxides, and low specific surface area, achieve high hydrothermal stability, improve catalytic combustion performance, and increase specific surface area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of the above-mentioned catalyst for the catalytic combustion of organic volatile waste gas, the specific steps are:

[0032] S1. According to the type of active components in the prepared catalyst, Fe 3+ Soluble salts and Ni 2+ 、Co 2+ , Zn 2+ , Mn 2+ 、Cu 2+ For four of the five soluble salts, dissolve the weighed soluble salts in deionized water, then add citric acid in proportion, and stir at room temperature for 2-4 hours to obtain a clear sol of mixed metal ions;

[0033] S2. Add a certain amount of γ-Al to the clarified sol of the above-mentioned mixed metal ions 2 o 3 The precursor of the carrier is stirred for 1-3h to obtain a mixture;

[0034] S3. Transfer the above mixture to water at 70-90°C, and evaporate the water under rapid stirring conditions to obtain a viscous gel;

[0035] S4. Transfer the prepared viscous gel to a vacuum oven and dry at 80-120°C for 12-24h. The obtained dried sample is ground and calcined at 600-1200°C fo...

Embodiment 1

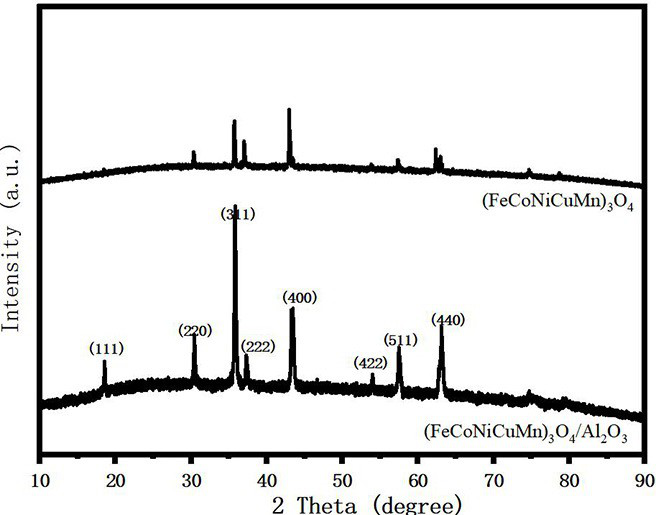

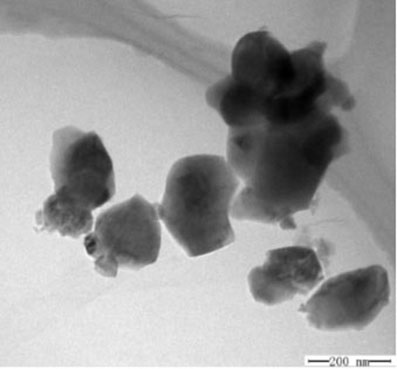

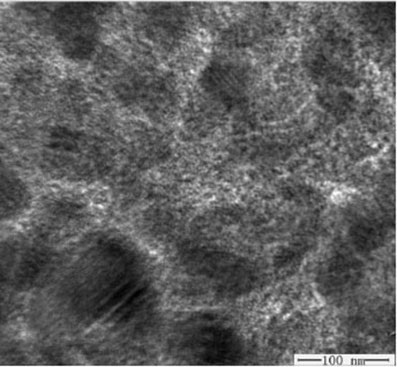

[0044] Weigh Fe(NO 3 ) 3 9H 2 O and Ni(NO 3 ) 2 ·6H 2 O, Co(NO 3 ) 2 ·6H 2 O, Zn(NO 3 ) 2 ·6H 2 O, Mn(NO 3 ) 2 4H 2 O, Cu(NO 3 ) 2 ·6H 2 O Dissolve any four of the five nitrates in deionized water (the total concentration of metal ions is 5 mol / L), then add citric acid in proportion (the molar ratio of citric acid to total metal ions is 3:1), at room temperature Stirring under the same conditions for 4 hours to obtain a clear sol of mixed metal ions; then add pseudo-boehmite powder according to the ratio of the mass loading of the obtained high-entropy oxide to 20%, and stir for 2 hours; The water was evaporated to dryness under rapid stirring conditions to obtain viscous gels; the prepared gels were transferred to a vacuum oven and dried at 120°C for 12 hours, and the dried samples were ground and calcined at 850°C for 4 hours to obtain supported type (FeCoNiCuMn) 3 o 4 / Al 2 o 3 , (FeCoZnCuMn) 3 o 4 / Al 2 o 3 , (FeZnNiCuMn) 3 o 4 / Al 2 o 3 , (FeC...

Embodiment 2

[0046] Prepare (FeCoNiCuMn) by the same method of embodiment 1 3 o 4 / Al 2 o 3 Catalysts, by adjusting the amount of pseudo-boehmite powder to change the loading of high-entropy oxides, prepared (FeCoNiCuMn) 3 o 4 The mass content is respectively 10%, 20% and 30% of supported high entropy oxide catalysts.

[0047] implement pour 3

[0048] The same method as in Example 2 prepared a load of 20% (FeCoNiCuMn) 3 o 4 / Al 2 o 3 Catalysts, changing the calcination temperature of high-entropy oxides, prepared (FeCoNiCuMn) calcined at 700 °C, 750 °C, 800 °C, 850 °C and 900 °C 3 o 4 / Al 2 o 3 catalyst.

[0049] by N 2 Adsorption / desorption method The specific surface area, pore volume and average pore diameter of the catalysts in Comparative Example 1 and Example 1 were measured, and the results are shown in Table 1.

[0050]

[0051] The data in Table 1 shows that the specific surface area and pore volume of Comparative Example 1 are very small, which can be considere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com