Kitchen waste sewage treatment system

A sewage treatment system and kitchen waste technology, applied in biological water/sewage treatment, flotation water/sewage treatment, water/sewage multi-stage treatment, etc., can solve problems such as insufficient strength, achieve strong water quality adaptability, and run Low cost, beneficial to the effect of adsorbing biofilm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0049] 1. Preparation of modified PVDC polymer

[0050] (1) Prepare the water phase: add 10wt% HPMC and 5wt% polyvinylpyrrolidone in water as a dispersant, stir to obtain the water phase;

[0051] (2) Prepare the oil phase: feed vinylidene chloride, 1,2-dichloroethylene, glycidyl methacrylate, and dimethyl diallyl ammonium chloride according to the mass ratio of 90:5:4:1, Then add 0.6wt% EHP of the total mass of the monomers as an initiator to prepare the oil phase;

[0052](3) Add the water phase to the oil phase, the mass ratio of the water phase and the oil phase is 1:1, heat to 80°C, maintain the temperature range, and polymerize under the stirring condition of 600rpm, the reaction time is 24h, filter, wash with water, and dry to prepare The obtained modified PVDC polymer had a weight-average molecular weight of 61,000, a PDI of 2.04, and a melting temperature of 142.8°C.

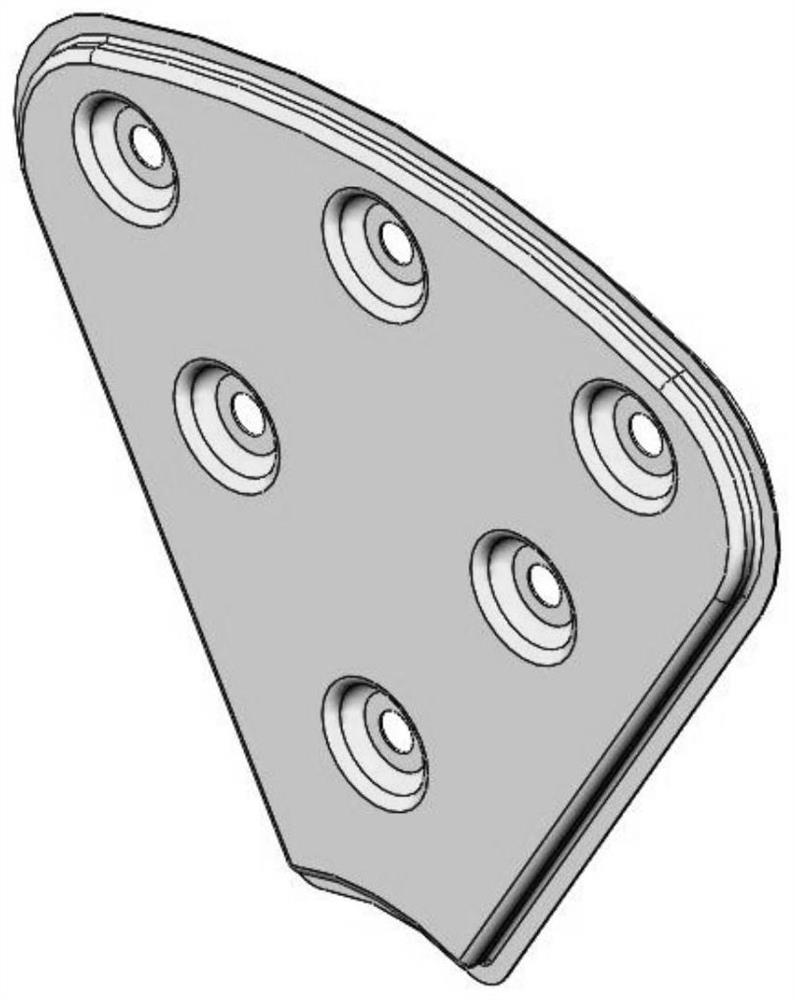

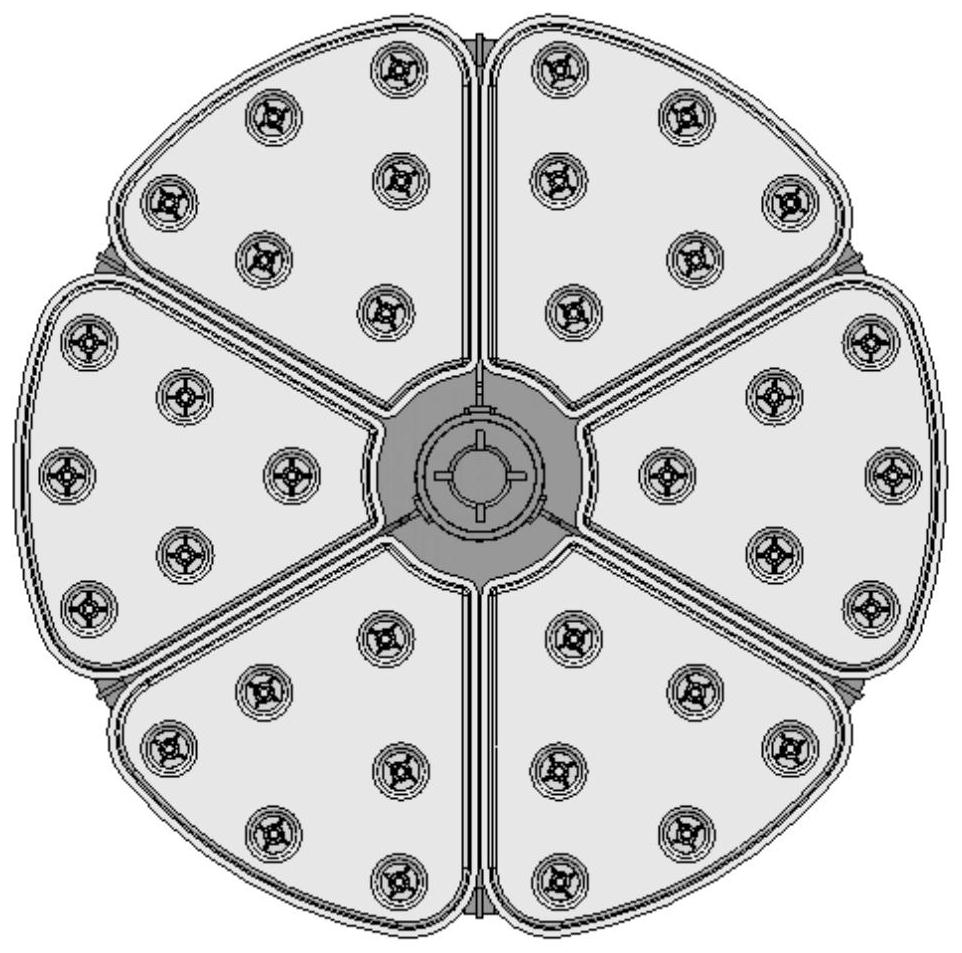

[0053] 2. Preparation of Biological Turntable Disc Material : After the preparation of the mod...

preparation example 2

[0059] Other conditions and steps are identical with preparation example 1, difference is that the preparation process of modified PVDC polymer is:

[0060] (1) Prepare the water phase: add 12wt% HPMC and 3wt% polyvinylpyrrolidone in water as a dispersant, stir to obtain the water phase;

[0061] (2) Prepare the oil phase: feed vinylidene chloride, 1,2-dichloroethylene, glycidyl methacrylate, and dimethyl diallyl ammonium chloride according to the mass ratio of 80:10:7:3, Then add 0.6wt% EHP of the total mass of the monomers as an initiator to prepare the oil phase;

[0062] (3) Add the water phase to the oil phase, the mass ratio of the water phase and the oil phase is 1:1, heat to 80°C, maintain the temperature range, and polymerize under the stirring condition of 600rpm, the reaction time is 24h, filter, wash with water, and dry to prepare The obtained modified PVDC polymer had a weight-average molecular weight of 62,000, a PDI of 2.09, and a melting temperature of 142.7°C...

preparation example 3

[0064] Other conditions and steps are identical with preparation example 1, difference is that the preparation process of modified PVDC polymer is:

[0065] (1) Prepare the water phase: add 10wt% HPMC and 5wt% polyvinylpyrrolidone in water as a dispersant, stir to obtain the water phase;

[0066] (2) Prepare the oil phase: feed vinylidene chloride, 1,2-dichloroethylene, glycidyl methacrylate, and dimethyl diallyl ammonium chloride according to the mass ratio of 87:6:5:2, Then add 0.6wt% EHP of the total mass of the monomers as an initiator to prepare the oil phase;

[0067] (3) Add the water phase to the oil phase, the mass ratio of the water phase and the oil phase is 1:1, heat to 80°C, maintain the temperature range, and polymerize under the stirring condition of 600rpm, the reaction time is 24h, filter, wash with water, and dry to prepare The obtained modified PVDC polymer had a weight-average molecular weight of 62,000, a PDI of 2.07, and a melting temperature of 142.5°C....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com