Metal-based energetic fragment with impact reaction activity and preparation method thereof

A reactive, metal-based technology, applied in offensive equipment, explosives processing equipment, explosives, etc., can solve the problems of low bonding degree of oxidizing agent and reducing agent, non-concentrated reaction process, low actual heat release, etc., and achieve good penetration and pore expansion ability, improved impact reactivity, and improved contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] According to the technical solution of the present invention, a specific method for preparing metal-based energetic fragments includes:

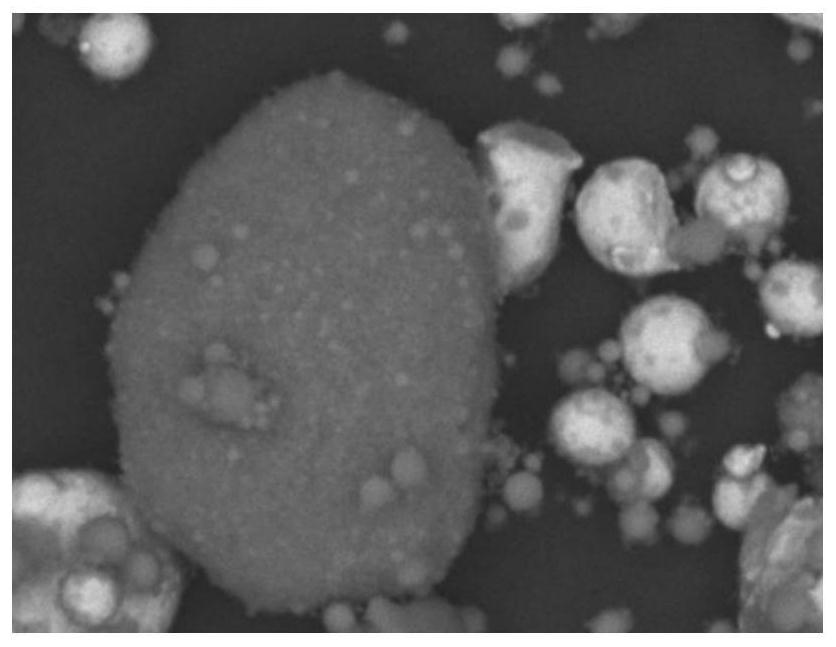

[0038] Step 1: Put the nickel powder in the dispersant solution, then add nano-aluminum to mix and dry, dry the mixed powder after drying, and then sieve to obtain the intermediate product of nano-aluminum powder coated micron nickel powder A;

[0039] Step 2: Fully shake and mix the obtained product A with metal oxide powder and microcrystalline wax;

[0040] Step 3: Add an organic solvent to the powder obtained after shaking in Step 2, perform wet ball milling, and then dry to obtain a metal oxide-coated product B;

[0041] Step 4: Molding the product B;

[0042] Step 5: Sintering the molded test piece to obtain the energetic fragment.

[0043] Among them, some preferred embodiments are:

[0044] The first step is to mix by mechanical stirring, and the stirring time is 2h-5h.

[0045] The time for dry ball milling in step 1 is ...

Embodiment 1

[0054] Metal-based energetic fragments were prepared by the following steps:

[0055] Weighing and stirring: place nickel powder with a particle size of 3 microns in an aqueous solution of sodium lauryl sulfate, add nano-aluminum powder according to the volume ratio of Al powder / Ni powder=3 / 7, stir for 2 hours, and then dry;

[0056] Dry grinding: add the dried mixed powder to the omnidirectional planetary ball mill, add nylon balls, the ball-to-material ratio is 4:1, and sieve after 5 hours of dry grinding to obtain nano-aluminum powder-coated micro-nickel powder;

[0057] Wet grinding: put the obtained powder in a vibrating sieve, add ferric oxide powder and microcrystalline wax in a mass ratio of 1:1:0.5 and shake for 3 hours, then put it in a planetary ball mill, add absolute ethanol, and wet grind Dry to obtain the final coated powder of ferric oxide;

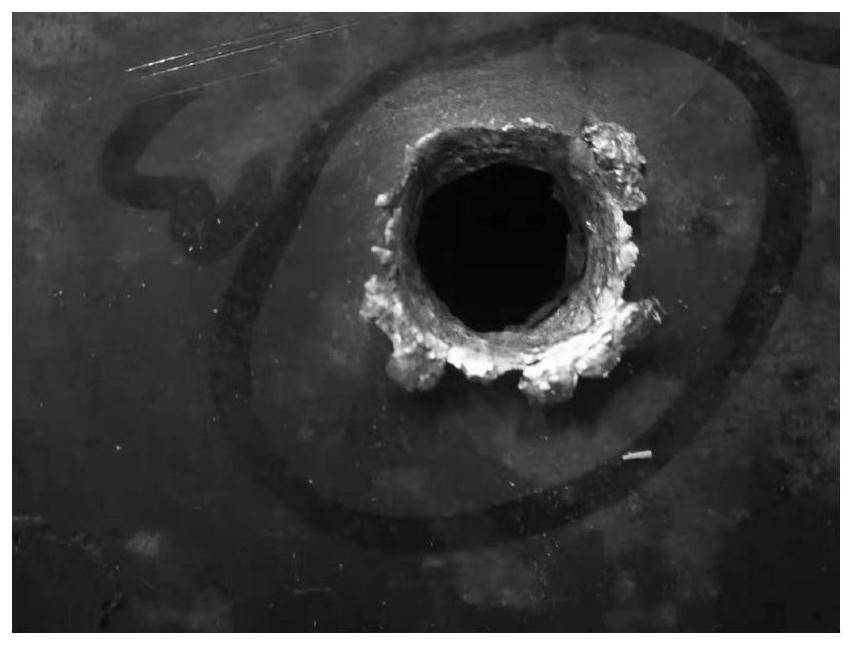

[0058] Molding: put the above-mentioned powder in a cylindrical mold for compression, the pressure is 30MPa, the pressu...

Embodiment 2

[0062] Metal-based energetic fragments were prepared by the following steps:

[0063] Weighing and stirring: Put the nickel powder in the aqueous solution of sodium lauryl sulfate, add nano-aluminum according to the volume ratio of Al powder / Ni powder = 1:1, stir for 3 hours and then dry;

[0064]Dry milling: Add the dried mixed powder into the omnidirectional planetary ball mill, add nylon balls, the ball-to-material ratio is 6:1, dry mill for 8 hours and sieve to obtain nano-aluminum powder-coated micro-nickel powder;

[0065] Wet grinding: put the above obtained powder in a vibrating sieve, add appropriate amount of copper oxide powder and microcrystalline wax to shake for 4 hours according to the mass ratio of 1:0.8:0.3, then place it in a planetary ball mill, add 10% polyvinyl alcohol, Drying after wet grinding to obtain the final coating powder of copper oxide;

[0066] Molding: put the above-mentioned powder in a cylindrical mold for compression, the pressure is 30MPa,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com