Preparation method of modified biomass charcoal composite chitosan-based adsorbent

A biochar and chitosan technology, applied in chemical instruments and methods, adsorption water/sewage treatment, water pollutants, etc., can solve the problems of low density, small size of biochar, difficult to separate, etc., and achieve adsorption performance Improve the effect of simple synthesis process and great application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

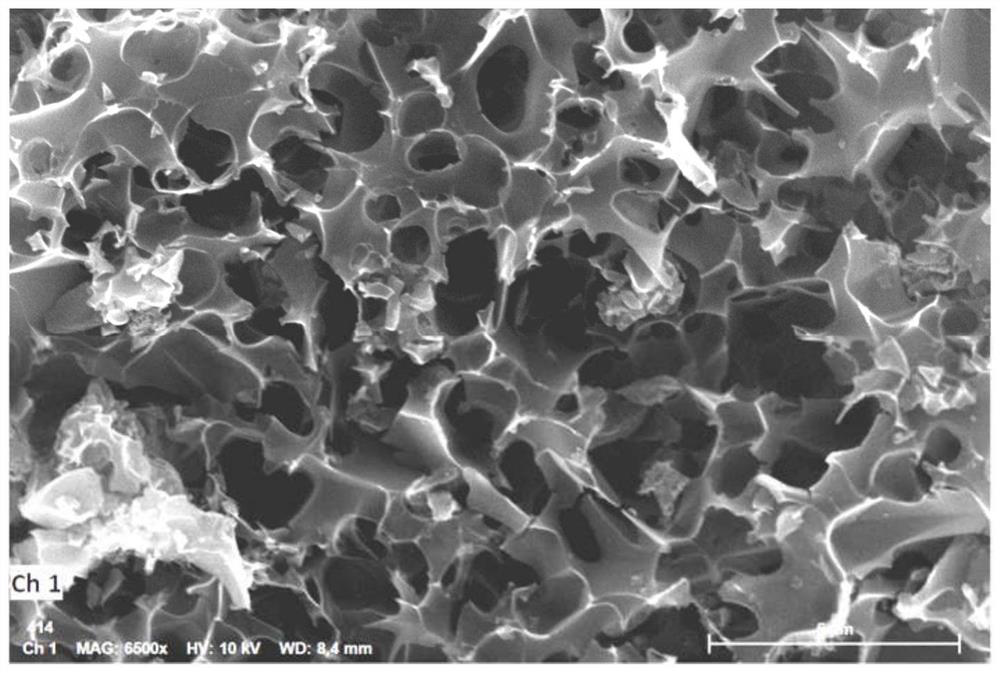

[0037] A preparation method of modified biochar composite chitosan-based adsorbent, comprising the steps of:

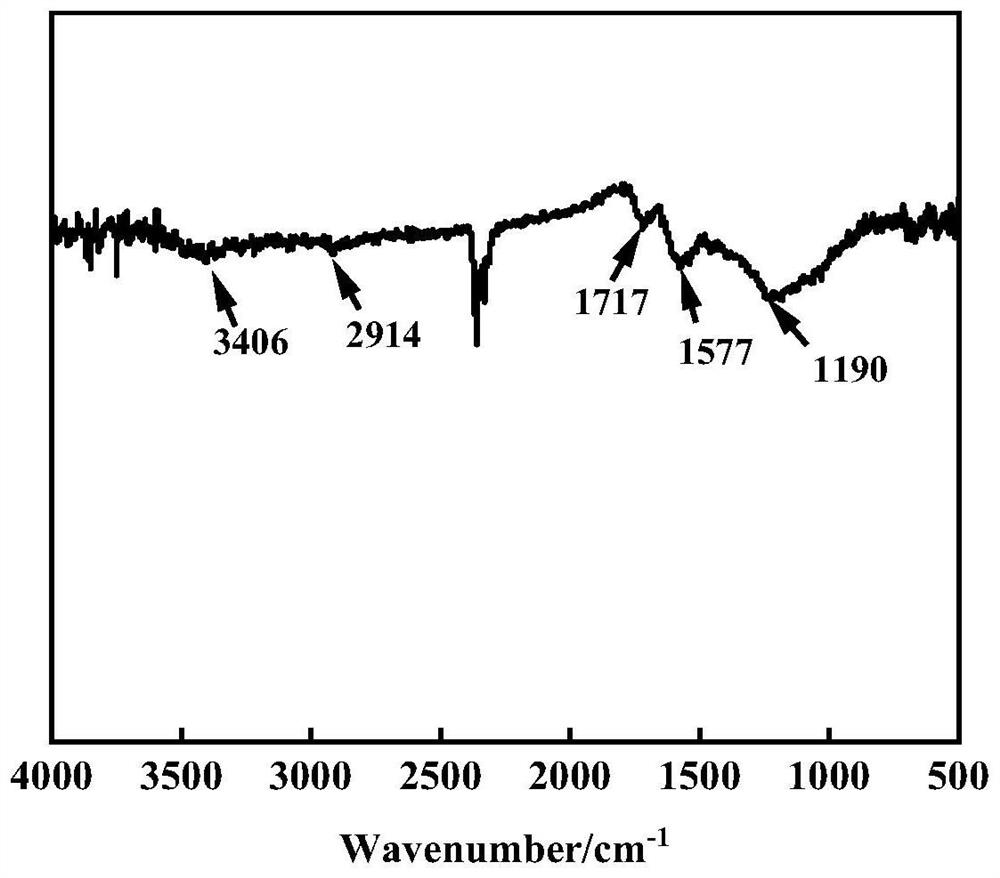

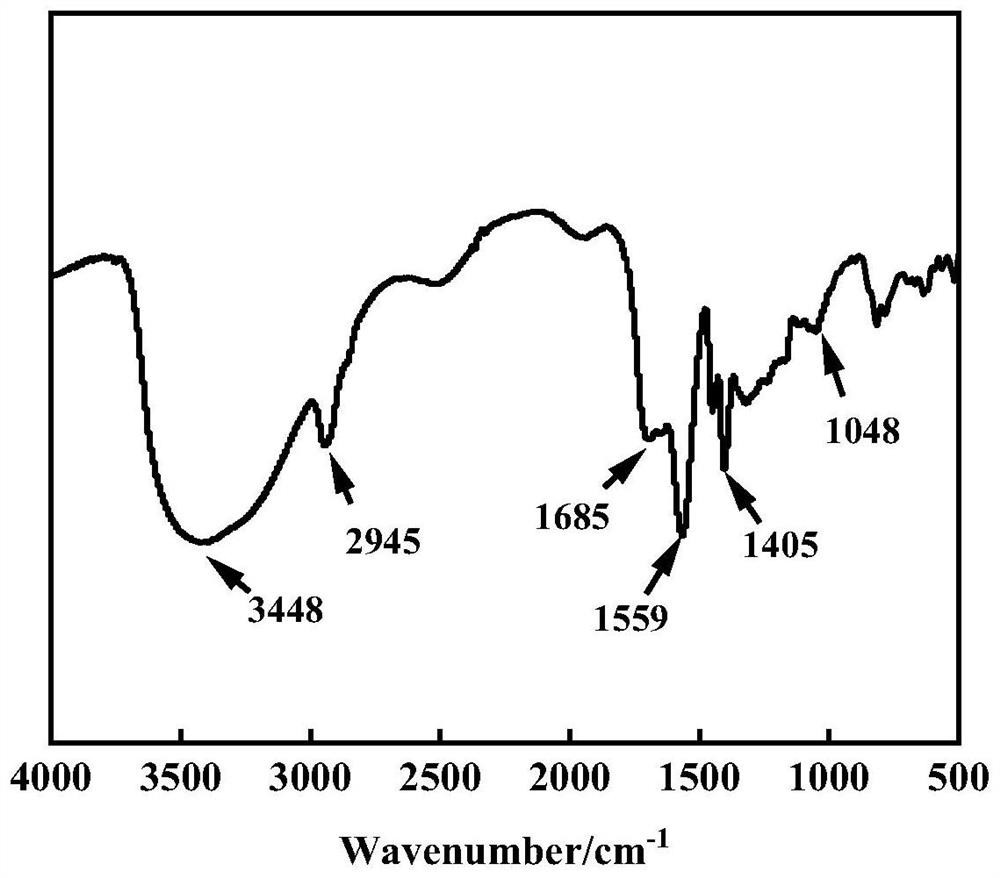

[0038] 1) Preparation of modified biochar: Disperse 2 g of natural cotton waste into 50 mL of 7 mol / L KOH solution, sonicate for 30 minutes, and then soak in vacuum for 20 h. Then, the excess KOH solution was filtered and dried for 24 hours to obtain a dry cotton / KOH mixture. The mixture was placed in a horizontal tube furnace and heated at 400°C under nitrogen for 0.5h, then raised to 800°C at a rate of 5°C / min and kept for 1h. After the sample was cooled, it was repeatedly washed with pure water until the pH was neutral, and then dried at 80 °C. Then, the dried sample was dispersed in 50mL 5mol / L HNO 3 solution, after magnetic stirring for 1 h, it was left overnight. Finally, filter out the HNO 3 solution, and the sample was washed with pure water until the pH value was neutral, and the sample obtained after drying was modified biochar.

[0039] 2) Weigh 2.6625...

Embodiment 2

[0042] A preparation method of modified biochar composite chitosan-based adsorbent, comprising the steps of:

[0043] 1) Preparation of modified biochar: Disperse 2 g of natural cotton waste into 50 mL of 7 mol / L KOH solution, sonicate for 30 minutes, and then soak in vacuum for 20 h. Then, the excess KOH solution was filtered and dried for 24 hours to obtain a dry cotton / KOH mixture. The mixture was placed in a horizontal tube furnace and heated at 400°C under nitrogen for 0.5h, then raised to 800°C at a rate of 5°C / min and kept for 1h. After the sample was cooled, it was repeatedly washed with pure water until the pH was neutral, and then dried at 80 °C. Then, the dried sample was dispersed in 50mL 5mol / L HNO 3 solution, after magnetic stirring for 1 h, it was left overnight. Finally, filter out the HNO 3 solution, and the sample was washed with pure water until the pH value was neutral, and the sample obtained after drying was modified biochar.

[0044] 2) Weigh 2.8673...

Embodiment 3

[0047] A preparation method of modified biochar composite chitosan-based adsorbent, comprising the steps of:

[0048] 1) Preparation of modified biochar: Disperse 2 g of natural cotton waste into 50 mL of 7 mol / L KOH solution, sonicate for 30 minutes, and then soak in vacuum for 20 h. Then, the excess KOH solution was filtered and dried for 24 hours to obtain a dry cotton / KOH mixture. The mixture was placed in a horizontal tube furnace and heated at 400°C under nitrogen for 0.5h, then raised to 800°C at a rate of 5°C / min and kept for 1h. After the sample was cooled, it was repeatedly washed with pure water until the pH was neutral, and then dried at 80 °C. Then, the dried sample was dispersed in 50mL 5mol / L HNO3 solution, stirred by magnetic force for 1h, and left overnight. Finally, the HNO3 solution was filtered out, and the sample was washed with pure water until the pH value was neutral, and the sample obtained after drying was modified biochar.

[0049] 2) Weigh 3.0720...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com