Preparation method of 7-ethyl chrotol

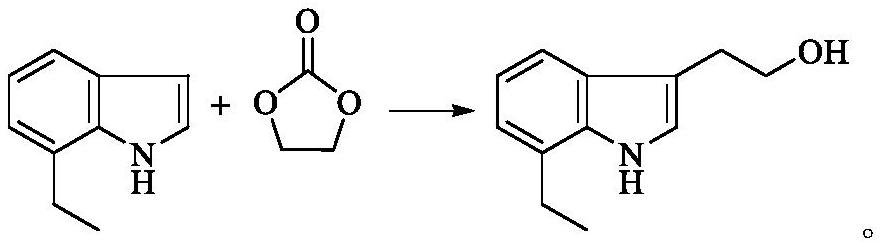

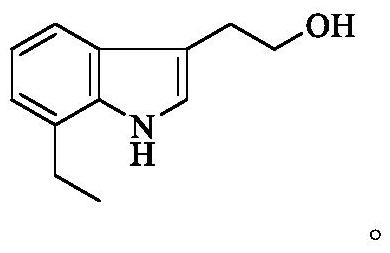

A technology of ethyl tryptol and ethyl indole, which is applied in the field of preparation of 7-ethyl tryptol, can solve the problems of high production cost, low yield, long process route, etc., and achieves improved operational safety and simplified production operation. , the effect of shortening the process route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] At room temperature, add 7-ethylindole (14.52g, 0.1mol) and potassium carbonate (16.58g, 0.12mol) into N,N-dimethylformamide (150ml), and add sulfite Ethyl ester (19.37g, 0.22mol), after the addition was completed, the temperature was controlled at 110-115°C until the reaction was completed, the reaction solution was cooled to room temperature and filtered, the filtrate was added with dichloromethane (100ml), and the organic phase was obtained by liquid separation. Washed with saturated brine (100ml×2), dried over anhydrous sodium sulfate, filtered, and the filtrate was concentrated to dryness under reduced pressure to obtain the target product with a yield of 98.7% and a purity of 99.92% by HPLC.

Embodiment 2

[0060] At room temperature, add 7-ethylindole (14.52g, 0.1mol) and potassium carbonate (13.82g, 0.1mol) into 1.4-dioxane (150ml), and add ethylene carbonate ( 19.37g, 0.22mol), the addition is completed, the temperature is controlled at 90-100°C until the reaction is completed, the reaction solution is cooled to room temperature and filtered, the filtrate is added with dichloromethane (100ml), the organic phase is separated, and the organic phase is washed with saturated saline (100ml×2) washed, dried over anhydrous sodium sulfate, filtered, and the filtrate was concentrated to dryness under reduced pressure to obtain the target product, with a yield of 94.6% and a HPLC purity of 99.86%.

Embodiment 3

[0062] At room temperature, add 7-ethylindole (14.52g, 0.1mol) and potassium carbonate (27.64g, 0.2mol) into xylene (150ml), and add ethylene carbonate (19.37g, 0.22 mol), the addition is completed, the temperature is controlled at 115-120 ° C until the reaction is over, the reaction solution is cooled to room temperature and filtered, the filtrate is added with dichloromethane (100ml), the liquid is separated to get the organic phase, and the organic phase is washed with saturated brine (100ml×2 ), dried over anhydrous sodium sulfate, filtered, and the filtrate was concentrated to dryness under reduced pressure to obtain the target product. The yield was 93.9%, and the HPLC purity was 99.76%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com