Polyether-based composite solid propellant 3D printing ink and preparation method thereof

A solid propellant and 3D printing technology, applied in the field of additive manufacturing, can solve the problems that affect the 3D printing process, difficulties, and difficulty in achieving self-leveling, achieve high printing resolution and complex structure forming capabilities, improve production safety, and reduce The effect of volume shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

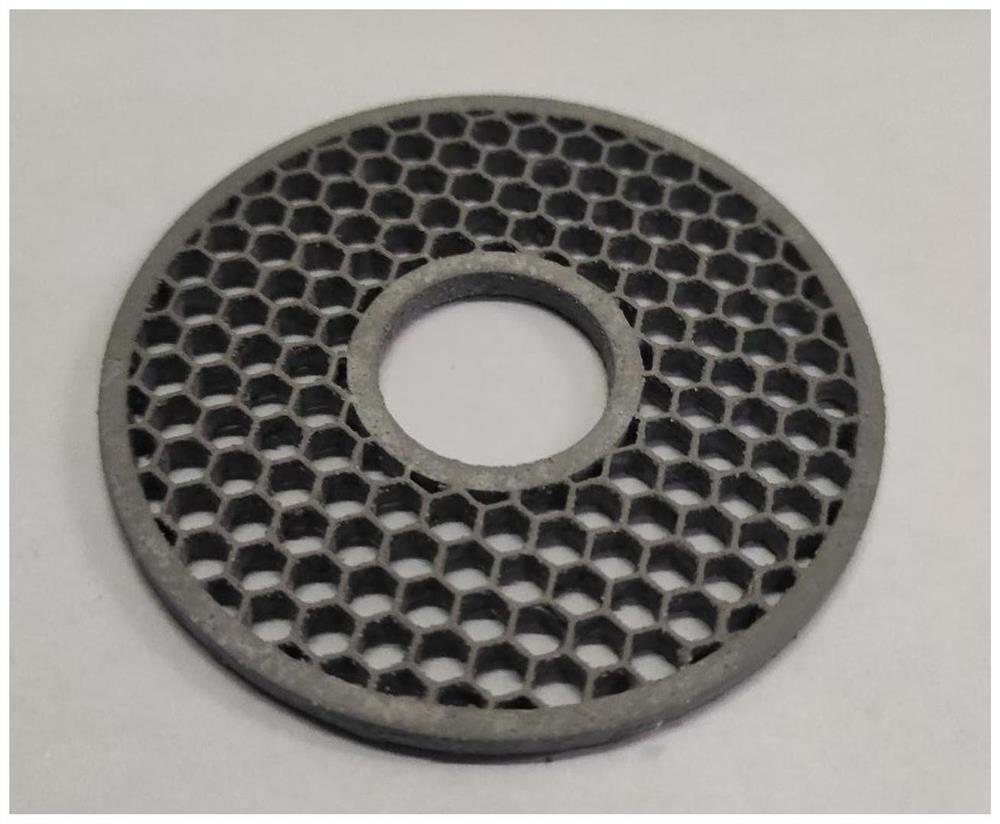

Image

Examples

Embodiment 1

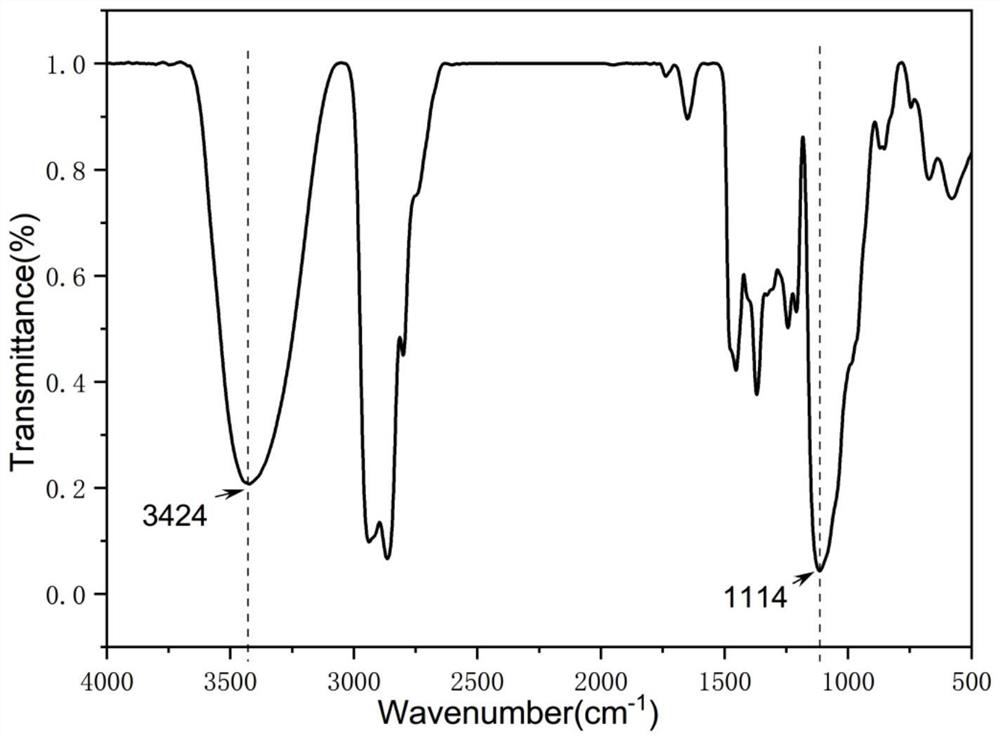

[0049] (1) Preparation of hyperbranched polyether macromonomer

[0050]

[0051] The present invention uses tetrahydrofuran and glycidyl alcohol as raw materials, boron trifluoride ether as a catalyst, reacts at 0°C-90°C for 1-10 hours, and prepares a hydroxyl-terminated hyperbranched polyether through cationic polymerization. Its structural formula is as follows: I) Shown:

[0052] Where a+b+c+d+e+f+g+h+i+j+k+l+m=15-50.

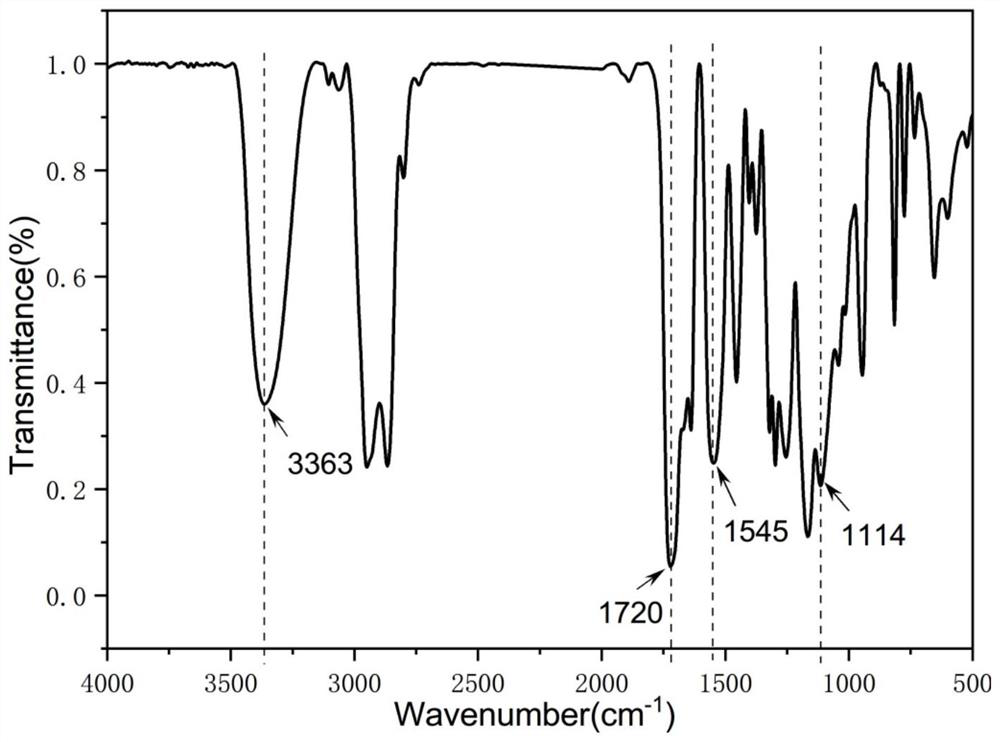

[0053] The present invention uses the hydroxyl-terminated hyperbranched polyether as a raw material, dissolves it in tetrahydrofuran together with isocyanoethyl methacrylate and DBTDL, reacts at room temperature for 12 hours and precipitates the reaction solution three times with petroleum ether to obtain a polyether type Polyurethane acrylate, its structural formula is shown in (II)

[0054]

[0055] Where a+b+c+d+e+f+g+h+i+j+k+l+m=15-50.

[0056] (2) Preparation of polyether-based composite solid propellant 3D printing ink

[0057] The present in...

Embodiment 2-6

[0063] Using the same preparation process and 3D printing technology as in Example 1, change the type of hyperbranched polyether macromonomer, diluent, crosslinking agent, plasticizer, oxidant, metal fuel, photoinitiator and dispersant and other parameters All the same as in Example 1, the prepared polyether-based composite solid propellant material ratio and breaking strength are shown in Table 1 below:

[0064] Table 1

[0065]

[0066]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Maximum tensile strength | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com